Remote control system of steel structure welding seam radiographic inspection device

A remote control system, radiographic flaw detection technology, applied in the direction of using radiation for material analysis, etc., can solve problems such as operator influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

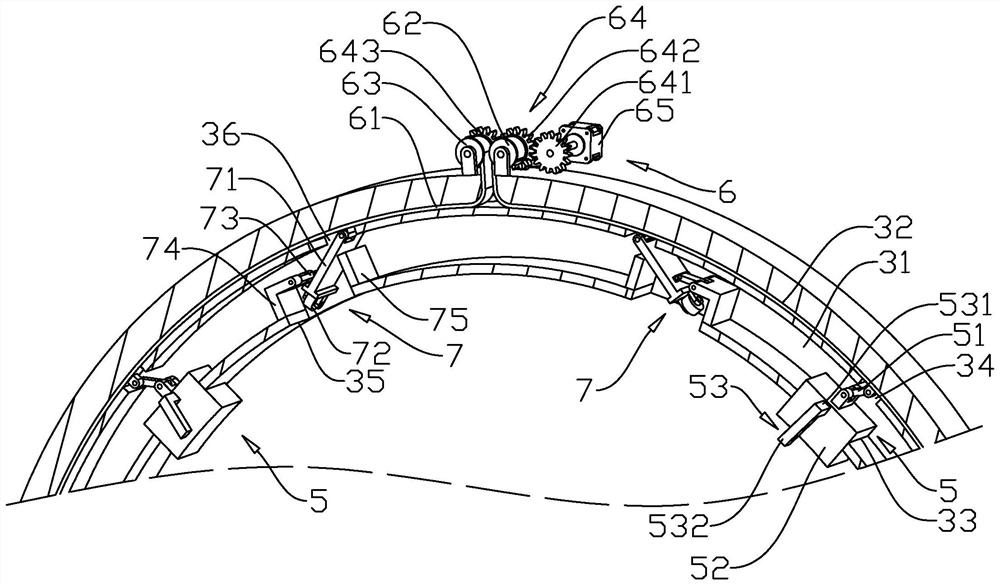

[0047] The following is attached Figure 1-8 The application is described in further detail.

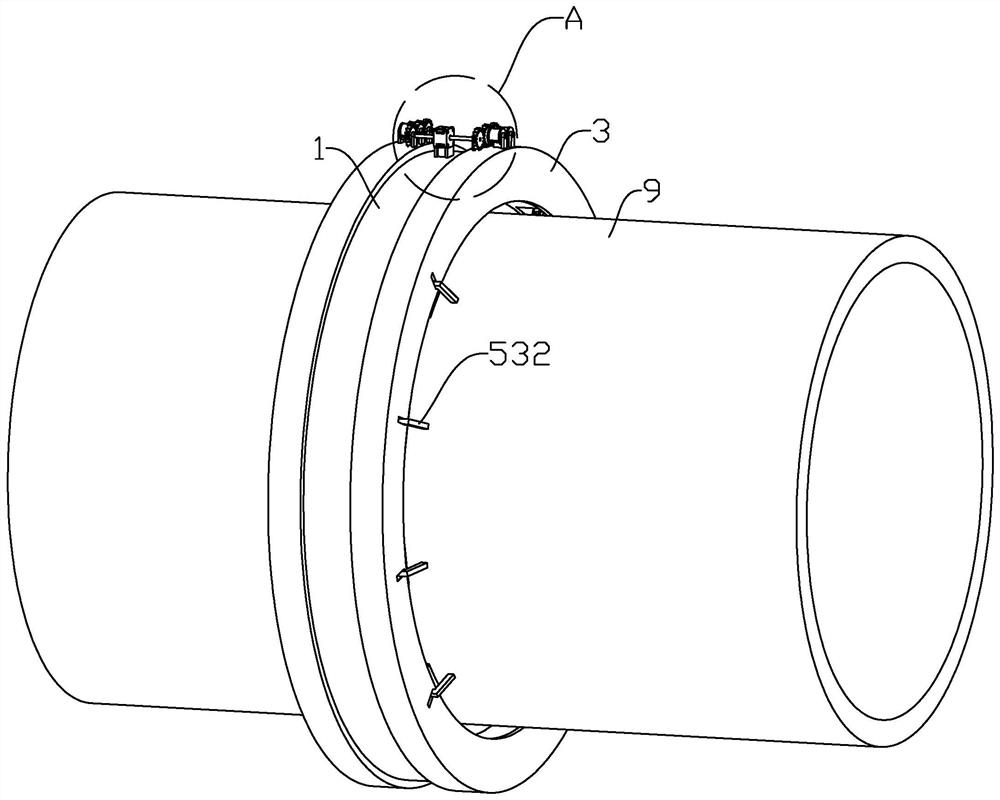

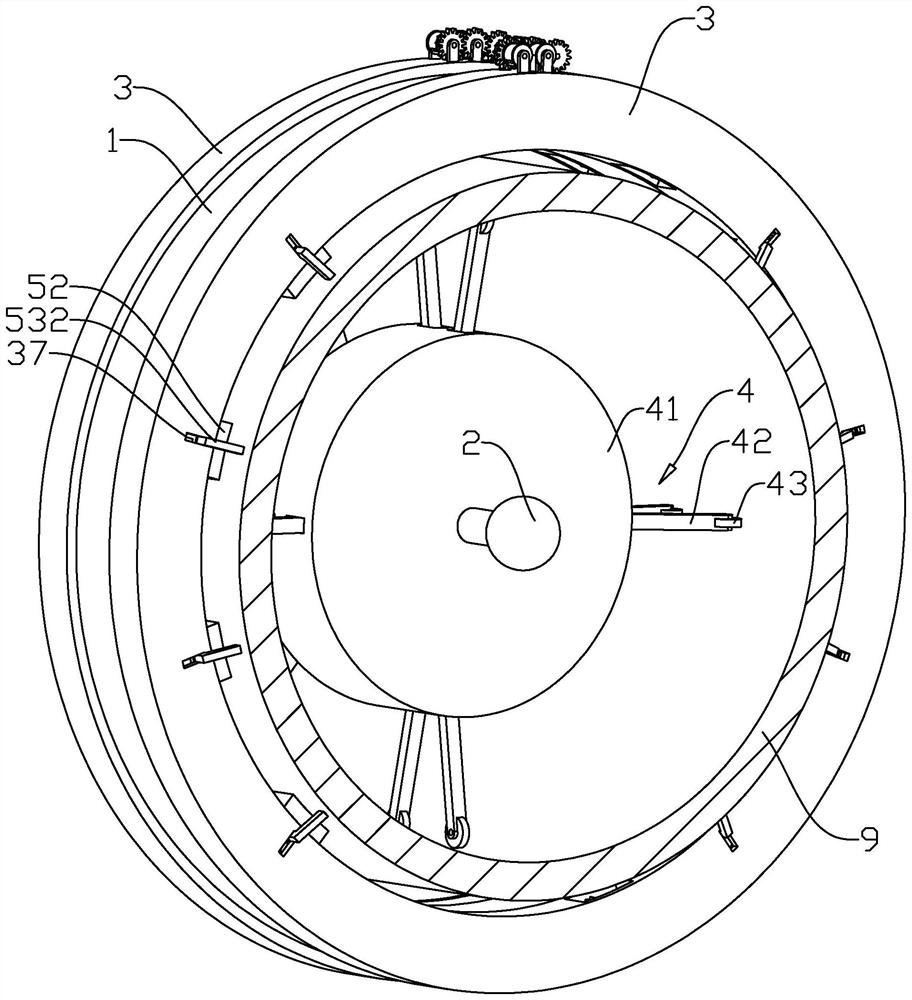

[0048] The embodiment of the present application discloses a remote control system of a radiographic flaw detection device for a weld seam of a steel structure. refer to figure 1 with figure 2 As shown, the remote control system of the steel structure weld seam radiographic flaw detection device includes an annular X-ray emission source 1 and an X-ray sensor 2, and both sides of the annular X-ray emission source 1 are fixedly connected with a fixed ring 3, and the two fixed rings The axis line of 3 coincides with the axis line of the annular X-ray emitting source 1. Both the two fixing rings 3 and the annular X-ray emission source 1 are sleeved on the steel pipe 9 , and each fixing ring 3 is provided with multiple sets of pressing components 5 for pressing against the surface of the steel pipe 9 . The X-ray sensor 2 is provided with a supporting device 4 , and the supporting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com