Initiating explosive device pressing system and method

A technology of pyrotechnic products and control systems, which is applied in the field of pyrotechnic product suppression, can solve the problems of difficult pressure adjustment, low pressure control accuracy, and difficulty in automatic integration, so as to shorten the pressing time, realize automatic integration, and shorten control the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

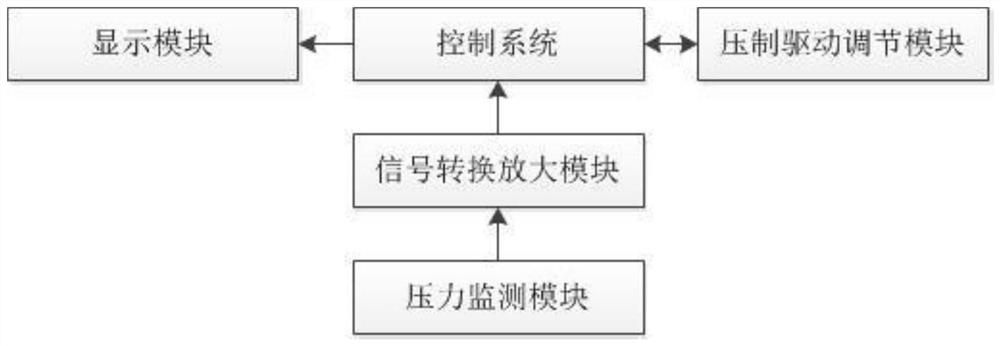

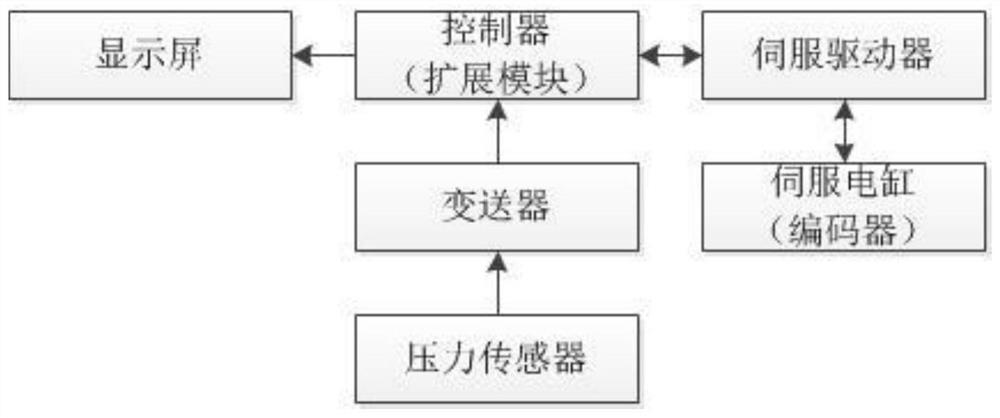

[0046] A pyrotechnic suppressing system, comprising:

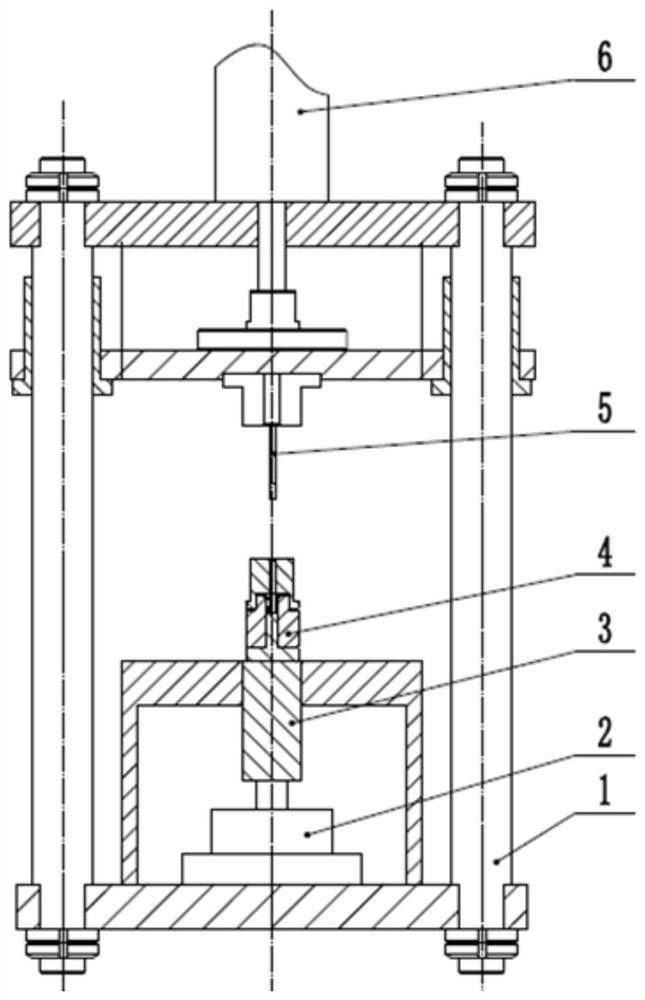

[0047] The punch 5 is used to suppress the pyrotechnic product 4;

[0048] Pressing and driving an adjustment mechanism, the pressing and driving adjustment mechanism is connected to the punch 5;

[0049] The pressure monitoring module is used to measure the pressure information of the pyrotechnic product 4 being suppressed;

[0050] The control system receives the pressure information, and controls the operating speed of the pressure-driven regulating mechanism according to the pressure information.

[0051] Specifically, the pressing actuator is a pressing driving adjustment mechanism, which moves and drives the punch 5 to suppress the pyrotechnic product 4, and the control system controls the output pressure of the pressing driving adjusting mechanism to act on the punch 5 , so that the punch 5 applies different pressing forces to the pyrotechnic product 4 according to the situation and at different stages. The press...

Embodiment 2

[0062] A pressing method, based on the pressing system of the above-mentioned embodiment 1, comprising:

[0063] S1: system start;

[0064] S2: When the pressure measured by the pressure monitoring module reaches the pressure mutation point, the system starts the closed-loop pressure control; this process includes:

[0065] S201: The control system controls the servo electric cylinder 6 to run from the working origin to the top of the pyrotechnic device with no load to reach the initial position;

[0066] S202: The control system controls the servo to operate the pressure detection displacement section, the pressure detection displacement section is the moving height of the servo electric cylinder 6 from the initial position to the position where the detection pressure is detected; in the pressure detection displacement section, the servo electric cylinder 6 Descending from the initial position, the punch 5 does not touch the pyrotechnic device, and the pressure sensor 2 cann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com