Near-zero emission system for deep treatment of coking strong brine

An advanced treatment, near-zero discharge technology, applied in sludge treatment, filtration treatment, water/sewage treatment, etc., can solve the problems of low concentration ratio of nanofiltration membrane, low market utilization value, complex composition of coking wastewater, etc. Excellent water purification effect, reducing the risk of clogging and corrosion, and the effect of clear and transparent effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

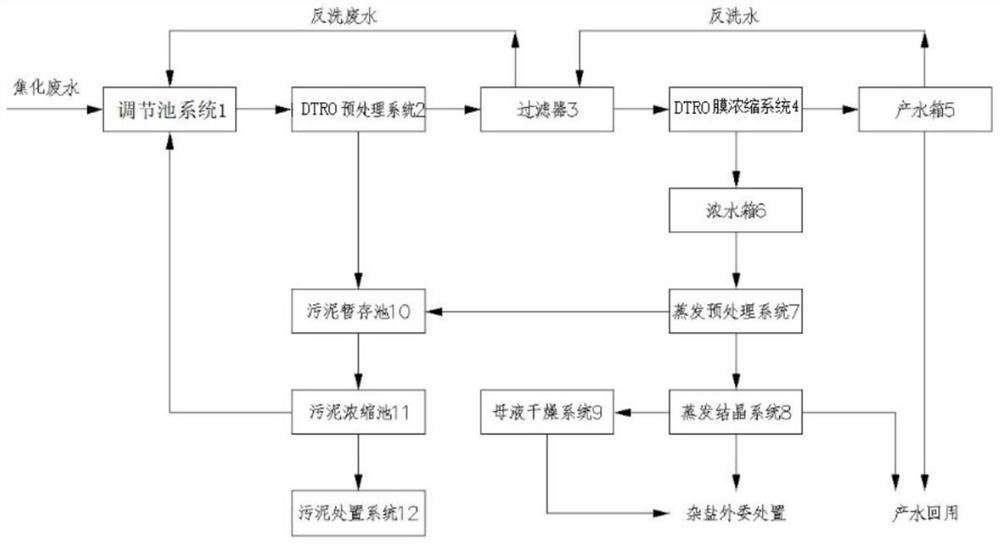

[0033] According to an embodiment of the present invention, a near-zero discharge system for advanced treatment of coking concentrated brine is provided, such as figure 1 As shown, it includes regulating tank system 1, DTRO (Disc tube reverse osmosis, disc tube reverse osmosis) pretreatment system 2, filter 3, DTRO membrane concentration system 4, product water tank 5, concentrated water tank 6, ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com