Defrosting air opening mechanism

A frost tuyere and sliding plate technology, applied in the field of defrosting tuyere mechanism, can solve the problems that the opening of defrosting tuyere cannot be adjusted in size, and the opening of defrosting tuyere cannot be closed, etc., and achieves the effects of low cost, preventing foreign objects from falling in, and simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

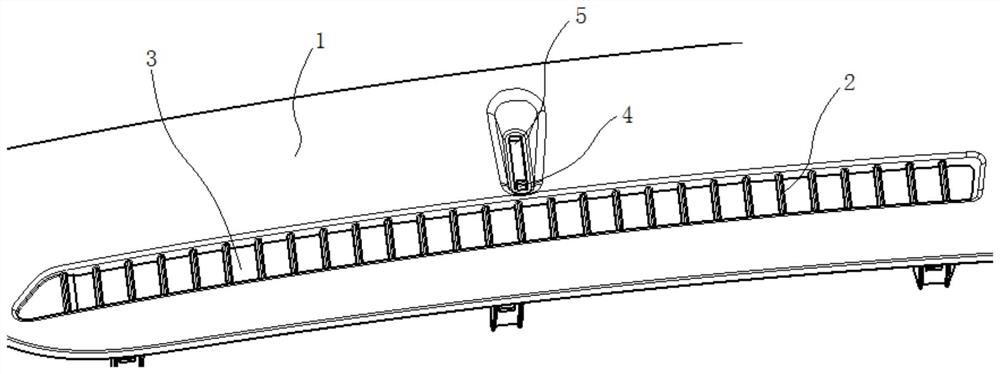

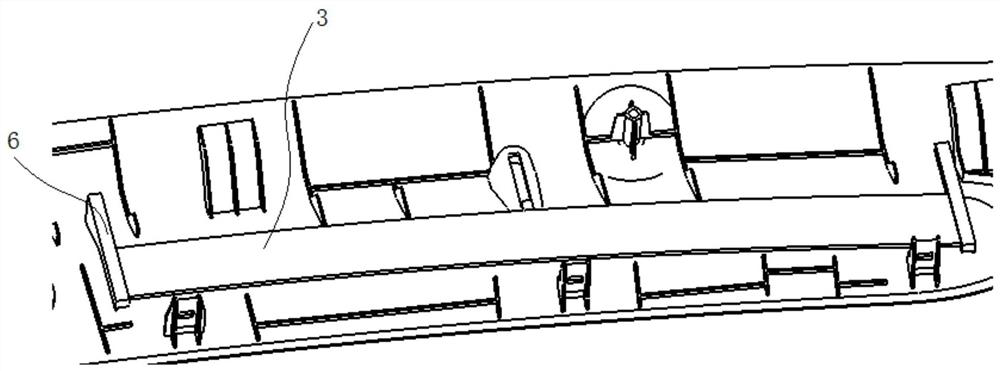

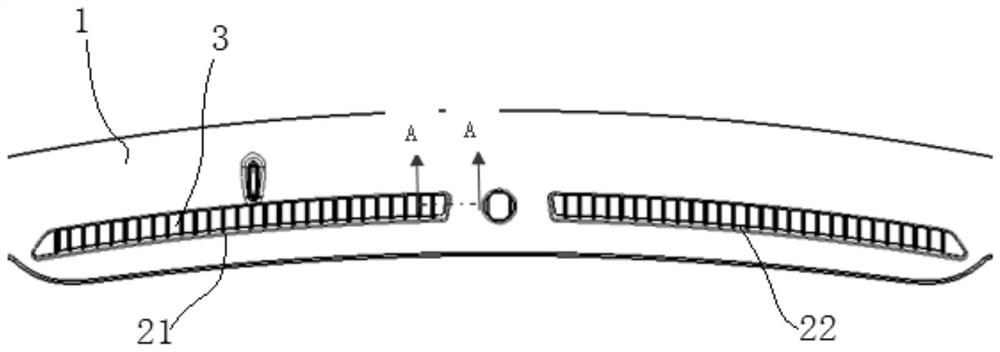

[0023] Such as Figure 1 to Figure 5 As shown, the present application provides a defrosting tuyere mechanism, including an instrument panel body 1 and a slide plate 3, and the slide plate is slidably connected to the instrument panel body; The structure is basically the same, and there is no need for major improvement. In this application, technologies such as the material of the instrument panel body are not involved, and the structure of the instrument panel body is not described in detail here. As for the instrument panel body, there are other parts Or the layout is designed according to the needs, and these aspects are not within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com