Antibacterial flame-retardant plywood and preparation method thereof

A technology of plywood and flame retardant layer, applied in the field of plywood, can solve the problems of heat resistance, poor durability, influence on appearance, high toxicity, etc., achieve simple manufacturing process and equipment, improve service life, high bonding strength and water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

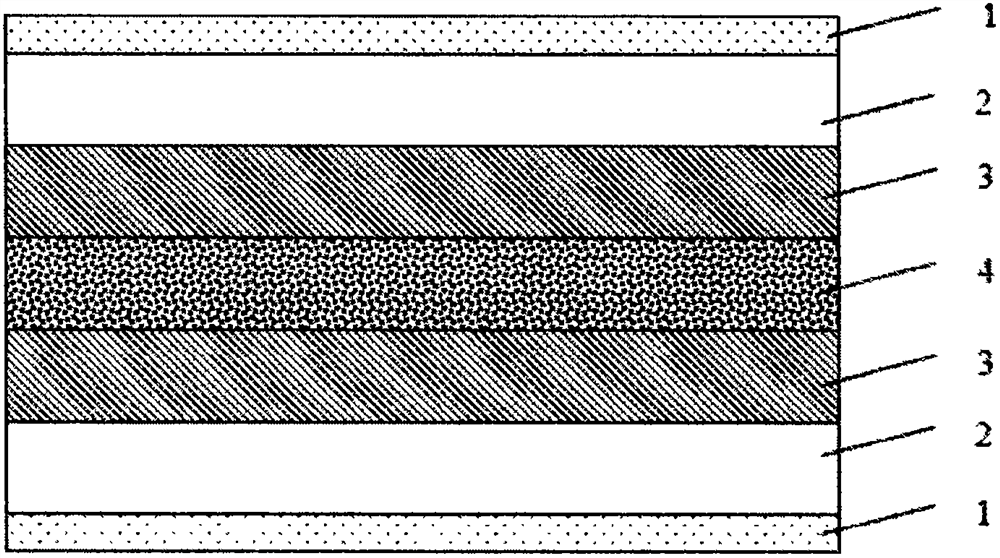

[0037] An antibacterial and flame retardant plywood such as figure 1 As shown, including paint layer 1, surface layer 2, flame retardant layer 3 and particle board layer 4;

[0038] Wherein, the particle board layer 4 is used as the base layer, and the flame-retardant layer 3, the surface layer 2 and the paint layer 1 are sequentially stacked on the upper surface and the lower surface;

[0039] Surface layer 2 is wood board; flame retardant layer 3 is flame retardant pc board;

[0040] The surface layer 2, the flame-retardant layer 3 and the particleboard layer 4 are bonded with an adhesive.

[0041] A preparation method for antibacterial and flame-retardant plywood, comprising the following steps:

[0042] (1) Weigh the following raw materials in proportion: 70 parts of polyvinyl alcohol, 1.3 parts of nano-magnesium oxide, 7 parts of acid-modified rosin resin, 4 parts of emulsifier, 6 parts of defatted soybean protein powder, 6 parts of starch, and 2 parts of nano-silver ,...

Embodiment 2

[0051] An antibacterial and flame retardant plywood such as figure 1 As shown, including paint layer 1, surface layer 2, flame retardant layer 3 and particle board layer 4;

[0052] Wherein, the particle board layer 4 is used as the base layer, and the flame-retardant layer 3, the surface layer 2 and the paint layer 1 are sequentially stacked on the upper surface and the lower surface;

[0053] Surface layer 2 is wood board; flame retardant layer 3 is flame retardant pc board;

[0054] The surface layer 2, the flame-retardant layer 3 and the particleboard layer 4 are bonded with an adhesive.

[0055] A preparation method for antibacterial and flame-retardant plywood, comprising the following steps:

[0056] (1) Weigh the following raw materials in proportion: 60 parts of polyvinyl alcohol, 1.2 parts of nano-magnesium oxide, 5 parts of acid-modified rosin resin, 3 parts of emulsifier, 5 parts of defatted soybean protein powder, 5 parts of starch, and 1 part of nano-silver , ...

Embodiment 3

[0065] An antibacterial and flame retardant plywood such as figure 1 As shown, including paint layer 1, surface layer 2, flame retardant layer 3 and particleboard layer 4;

[0066] Wherein, the particle board layer 4 is used as the base layer, and the flame-retardant layer 3, the surface layer 2 and the paint layer 1 are sequentially stacked on the upper surface and the lower surface;

[0067] Surface layer 2 is wood board; flame retardant layer 3 is flame retardant pc board;

[0068] The surface layer 2, the flame-retardant layer 3 and the particleboard layer 4 are bonded with an adhesive.

[0069] A preparation method for antibacterial and flame-retardant plywood, comprising the following steps:

[0070] (1) Weigh the following raw materials in proportion: 80 parts of polyvinyl alcohol, 1.5 parts of nano-magnesium oxide, 10 parts of acid-modified rosin resin, 5 parts of emulsifier, 7 parts of defatted soybean protein powder, 7 parts of starch, and 3 parts of nano-silver ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com