Reciprocating type self-control rotating magnetic field magnetorheological polishing machine

A magnetorheological polishing, rotating magnetic field technology, applied in grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc., can solve the problems of single form and low efficiency, improve mechanical precision and improve polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

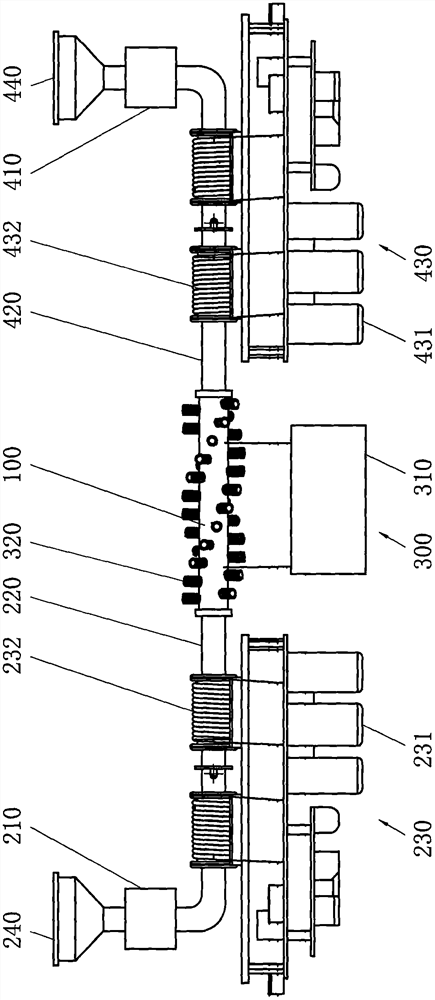

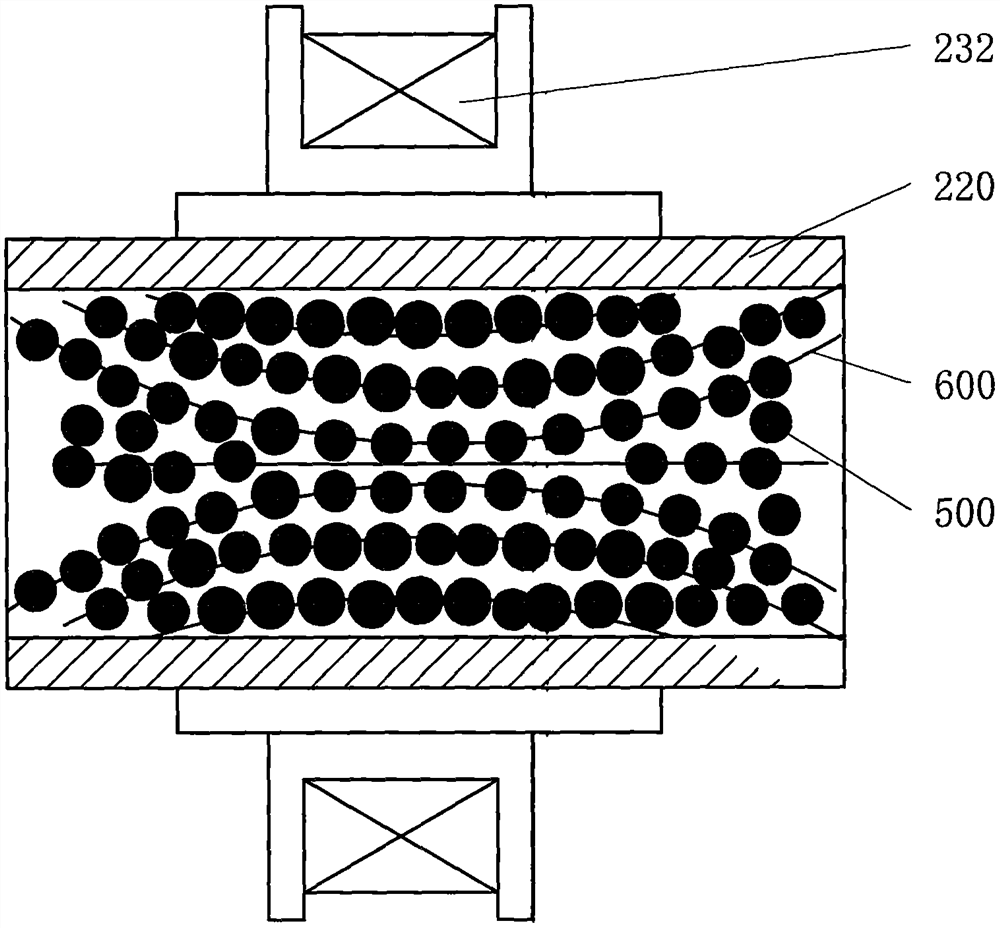

[0023] Reciprocating self-controlled rotating magnetic field magnetorheological polishing machine, used to polish the inner wall of pipe fittings, including left reducer, left liquid inlet pipe, left magnetorheological fluid accelerator, rotating magnetic field mechanism, right liquid inlet pipe, right magnetorheological fluid accelerator , right speed reducer and magnetorheological polishing fluid, the two ends of the pipe fittings are connected with one end of the left liquid inlet pipe and one end of the right liquid inlet pipe respectively, the middle part of the left liquid inlet pipe is provided with the left magnetorheological A liquid accelerator, the end of the left liquid inlet pipe far away from the pipe fitting is provided with the left speed reducer; the middle part of the right liquid inlet pipe is provided with the right magnetorheological fluid accelerator, and the end of the right liquid inlet pipe far away from the pipe fitting The right speed reducer is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com