Fixing device for new energy automobile battery pack box frame and automatic welding system

A technology for new energy vehicles and fixtures, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve problems such as easy deformation, and achieve the effect of reducing the possibility of deformation and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

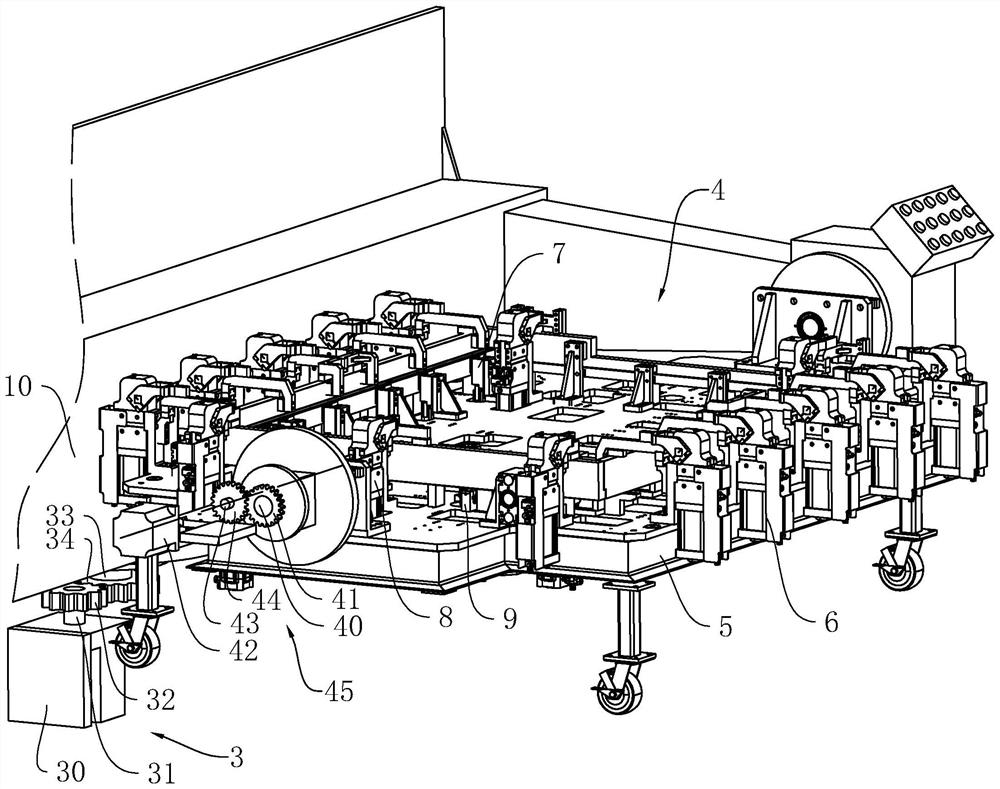

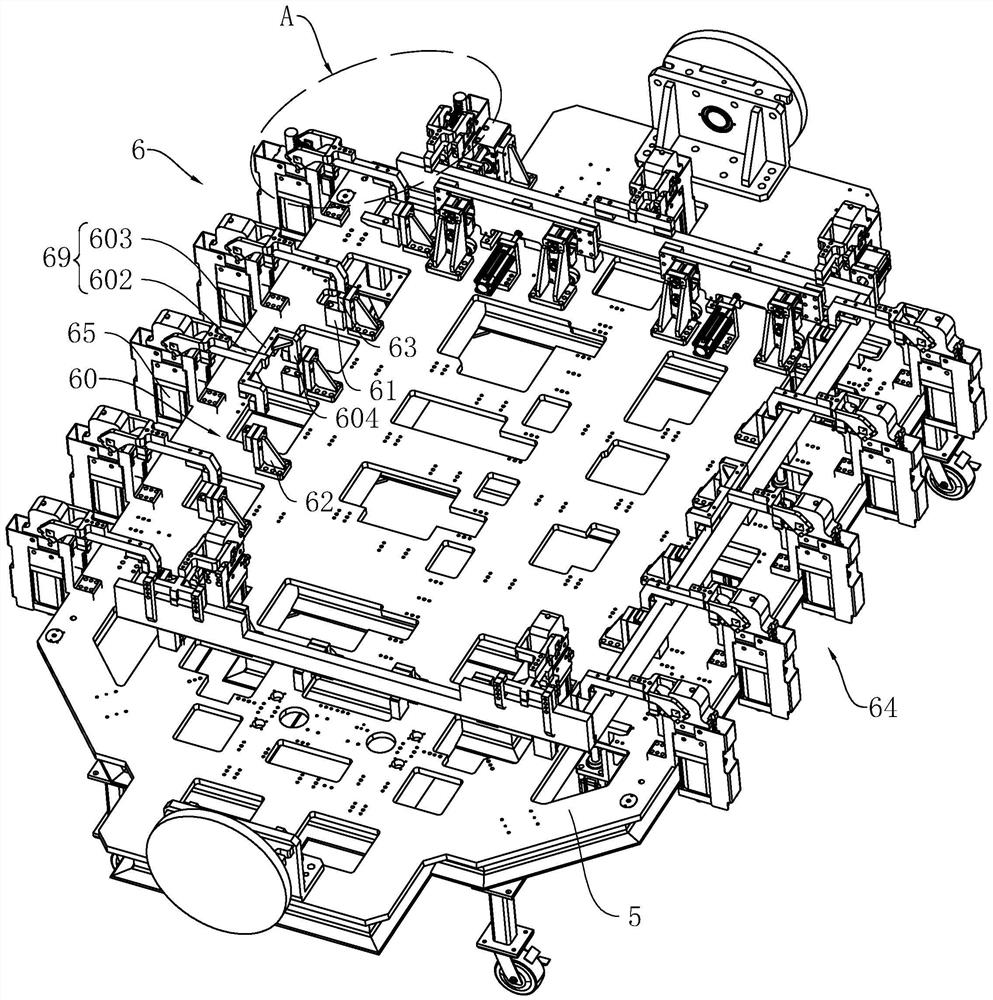

[0061] refer to figure 1 with figure 2 , a new energy vehicle battery pack box frame fixing device and automatic welding system, including a base 1 and a welding robot 12 for welding the box frame, the welding robot 12 is arranged on one side of the base 1, and the base 1 is provided with The turret 10, the base 1 is provided with a power unit 3 that drives the turret 10 to rotate horizontally, the turret 10 is provided with a fixing device 4, the number of the fixing devices 4 is two, and the two fixing devices 4 are arranged oppositely. A partition 11 for separating the two fixing devices 4 is provided, which can reduce the possibility of scalding workers caused by welding sparks.

[0062] refer to figure 1 with figure 2 , the turret 10 is provided with a drive unit 45 for driving the fixture 4 to turn over; when welding is required, the drive unit 45 drives the fixture 4 to turn over to be a vertical device, and the workman will first set of crossbars, beams, vertical ...

Embodiment 2

[0083] refer to Figure 9 , The difference between this embodiment and Embodiment 1 is that it also includes a feeding device 2; Assemblies 21 , the frame 20 is provided with a conveying assembly 22 for conveying crossbars and beams, and the frame 20 is provided with a picking assembly 23 for moving the crossbars and beams from the output assembly 21 to the conveying assembly 22 .

[0084] refer to Figure 9 , the frame 20 is provided with a clamping assembly 24 for mounting the cross bar and the beam on the fixture 4, the clamping assembly 24 is located between the conveying assembly 22 and the fixture 4, and the frame 20 is provided with a clamping assembly 24 for mounting the longitudinal bar The moving assembly 25 installed on the fixing device 4 with the longitudinal beam, the moving assembly 25 is located between the output assembly 21 and the fixing device 4 .

[0085] refer to Figure 9 with Figure 10 , the conveying assembly 22 includes a conveying motor 220 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com