Process for preparing polysaccharide-based fat meat tissue based on microcapsule technology

A microcapsule and process technology, applied in the field of vegetable protein meat, can solve problems such as application limitation and oil leakage, and achieve the effect of improving cooking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

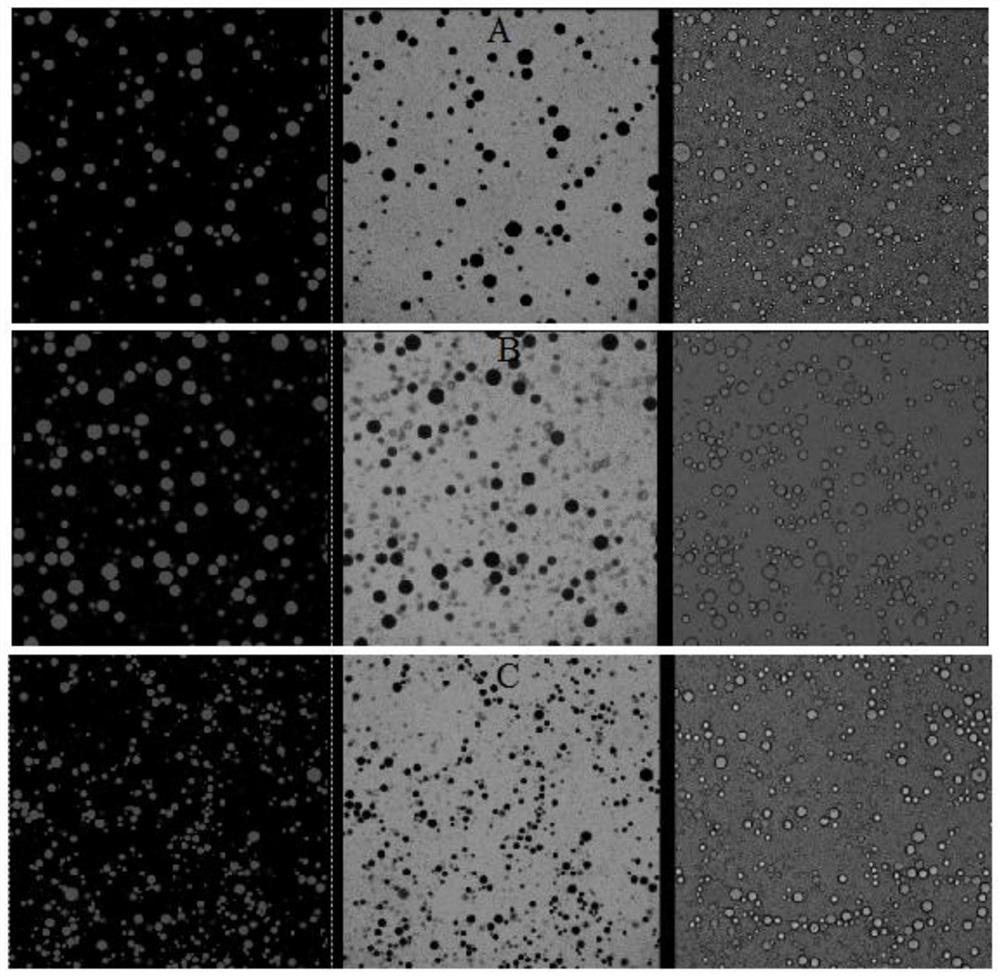

Embodiment 1

[0049] Soak the soybeans at 25°C for 12 hours, then add 3 times the amount of water to the soaked wet soybeans, colloidally grind for 2 minutes, and filter with three layers of gauze to obtain the filtrate. Add 10% sucrose to the filtrate and dissolve completely. After incubating at 65° C. for 30 minutes, the mixture was placed in a 1 L centrifuge tube, and centrifuged at 4° C. with a centrifugal force of 10,000 g for 20 minutes to obtain soybean oil bodies (floating substances).

[0050] Add 2 times of water to the soybean oil body, add 1% soybean protein isolate by solution weight and mix evenly. Coconut oil and the mixed solution were homogeneously emulsified at 9500r / min for 3min at 40°C at a mass ratio of 1:1 to obtain an emulsion.

[0051] The emulsion was kept warm at 40°C, and 0.5% chitosan solution (dissolved with 0.3% glacial acetic acid) was added to the emulsion while stirring, the mass ratio of emulsion to chitosan was 30:1, and the pH was adjusted to 6. The obt...

Embodiment 2

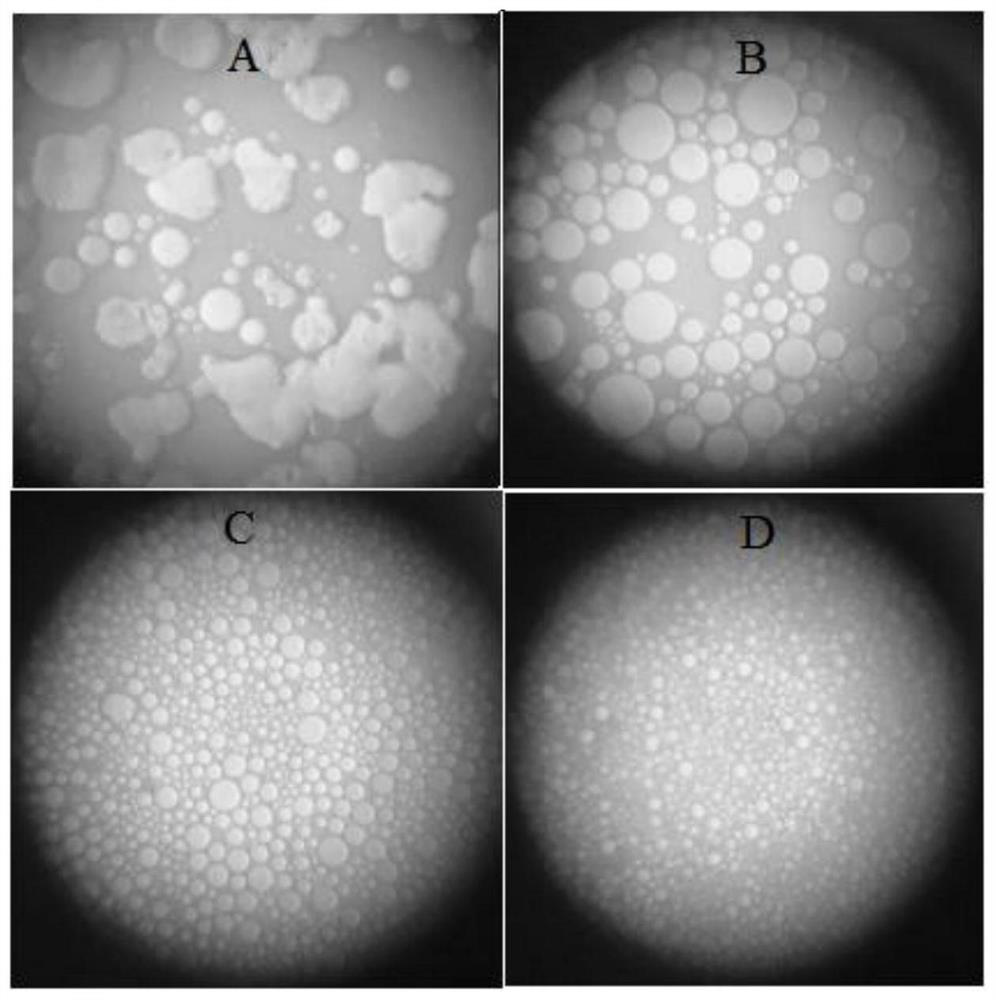

[0068] This example is to study the influence of different emulsification time and emulsification rotational speed on the emulsification effect.

[0069] Soak the soybeans at 25°C for 12 hours, then add 3 times the amount of water to the soaked wet soybeans, colloidally grind for 2 minutes, and filter with three layers of gauze to obtain the filtrate. Add 10% sucrose to the filtrate and dissolve completely. After incubating at 65° C. for 30 minutes, the mixture was placed in a 1 L centrifuge tube, and centrifuged at 4° C. with a centrifugal force of 10,000 g for 20 minutes to obtain soybean oil bodies (floating substances).

[0070] Add 2 times of water to the soybean oil body, add 1% soybean protein isolate by solution weight and mix evenly. The coconut oil and the mixed solution are in a mass ratio of 1:1 at 40°C.

[0071] The emulsion was kept warm at 40°C, and 0.5% chitosan solution (dissolved with 0.3% glacial acetic acid) was added to the emulsion while stirring, the m...

Embodiment 3

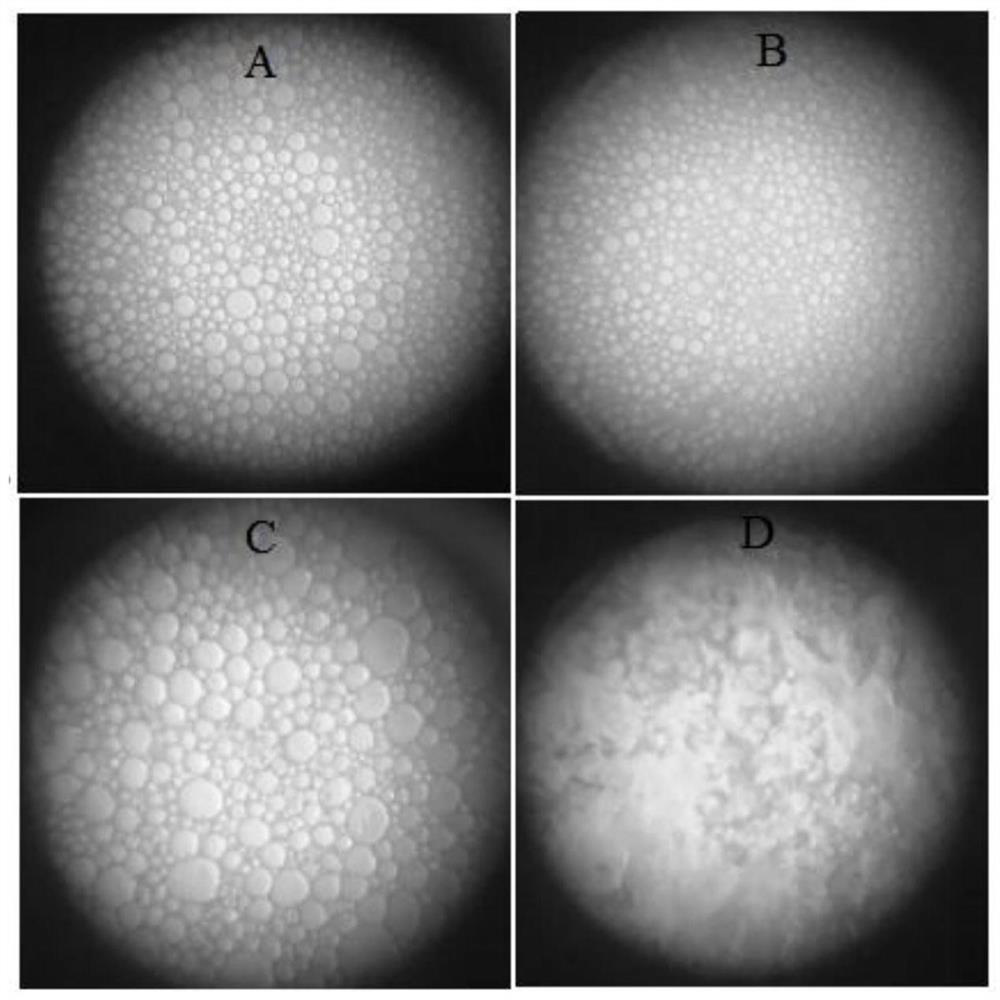

[0075] This embodiment is to study the impact of the ratio of coconut oil and mixed solution on the preparation of microcapsules.

[0076] Soak the soybeans at 25°C for 12 hours, then add 3 times the amount of water to the soaked wet soybeans, colloidally grind for 2 minutes, and filter with three layers of gauze to obtain the filtrate. Add 10% sucrose to the filtrate and dissolve completely. After incubating at 65° C. for 30 minutes, the mixture was placed in a 1 L centrifuge tube, and centrifuged at 4° C. with a centrifugal force of 10,000 g for 20 minutes to obtain soybean oil bodies (floating substances).

[0077] Add 2 times of water to the soybean oil body, add 1% soybean protein isolate by weight of the solution, mix evenly, and homogeneously emulsify at 9500 r / min for 3 minutes at 40°C to obtain an emulsion.

[0078] The emulsion was kept warm at 40°C, and 0.5% chitosan solution (dissolved with 0.3% glacial acetic acid) was added to the emulsion while stirring, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com