High-cereal dietary fiber staple food reconstituted bread premixed flour, and bread and preparation method thereof

A dietary fiber powder and dietary fiber technology, applied in the food field, can solve the problems of difficult bread molding, difficult taste, and reduced bread quality, and achieve the effects of facilitating market promotion, long preparation time, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

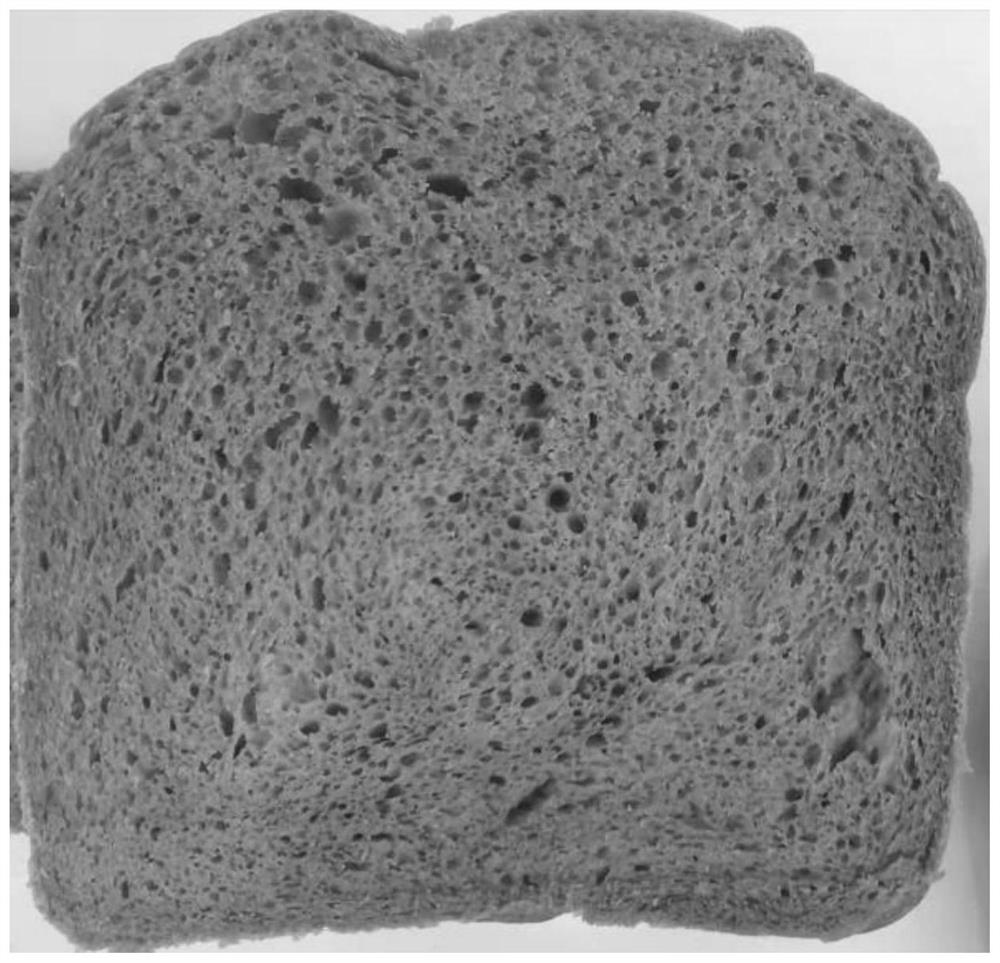

Embodiment 1

[0068] Add high grain dietary fiber staple food reconstituted bread mix to the bread machine. The formula of the high grain dietary fiber staple food reconstituted bread premix of the present embodiment after adding dry yeast is: 105 parts of wheat bran, 90 parts of vegetable protein, 25 parts of potato starch, 25 parts of tapioca starch, 22 parts of resistant dextrin, 5 parts of dry yeast, 3 parts of edible salt, 0.2 part of mogroside.

[0069] Start the bread machine program, the specific parameters are designed as:

[0070] (1) Automatic water addition: 250 parts by weight;

[0071] (2) Knead the dough: the time is 20 minutes, the temperature is normal temperature but not higher than 30°C;

[0072] (3) Fermentation: time 30 minutes, temperature about 37°C;

[0073] (4) Baking: the time is 40 minutes, and the temperature is about 160°C.

[0074] In this example, two kinds of starches are added to balance the mouthfeel and blood sugar.

Embodiment 2

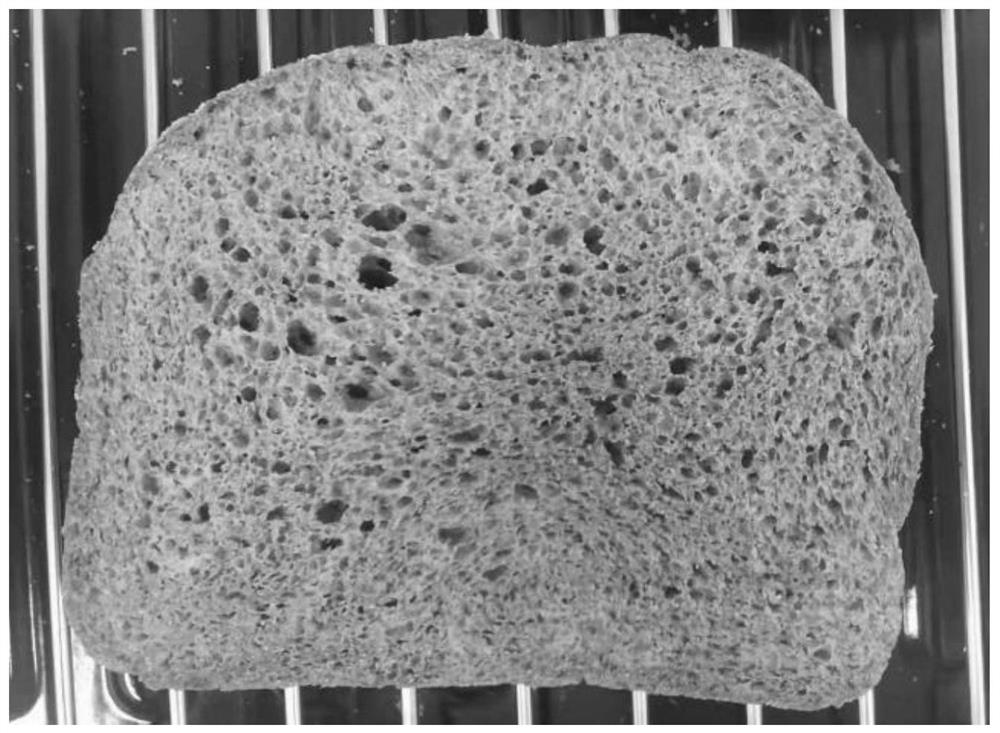

[0075] Example 2 (Catalog B#0730)

[0076] Add high grain dietary fiber staple food reconstituted bread mix to the bread machine. The formula of the high grain dietary fiber staple food reconstituted bread premix of the present embodiment after adding dry yeast is: 52 parts of wheat bran, 50 parts of oat bran, 87 parts of vegetable protein, 28 parts of tapioca starch, 24 parts of potato starch, anti- 18 parts of sex dextrin, 5 parts of inulin, 5 parts of dry yeast, 3 parts of edible salt, 0.2 part of mogroside.

[0077] Start the bread machine program, the specific parameters are designed as:

[0078] (1) Automatic water addition: 245 parts by weight;

[0079] (2) Knead the dough: the time is 30 minutes, the temperature is normal temperature but not higher than 30°C;

[0080] (3) Fermentation: time 60 minutes, temperature about 37°C;

[0081] (4) Baking: the time is 30 minutes, and the temperature is about 160°C.

[0082] In this example, two kinds of starches are added t...

Embodiment 3

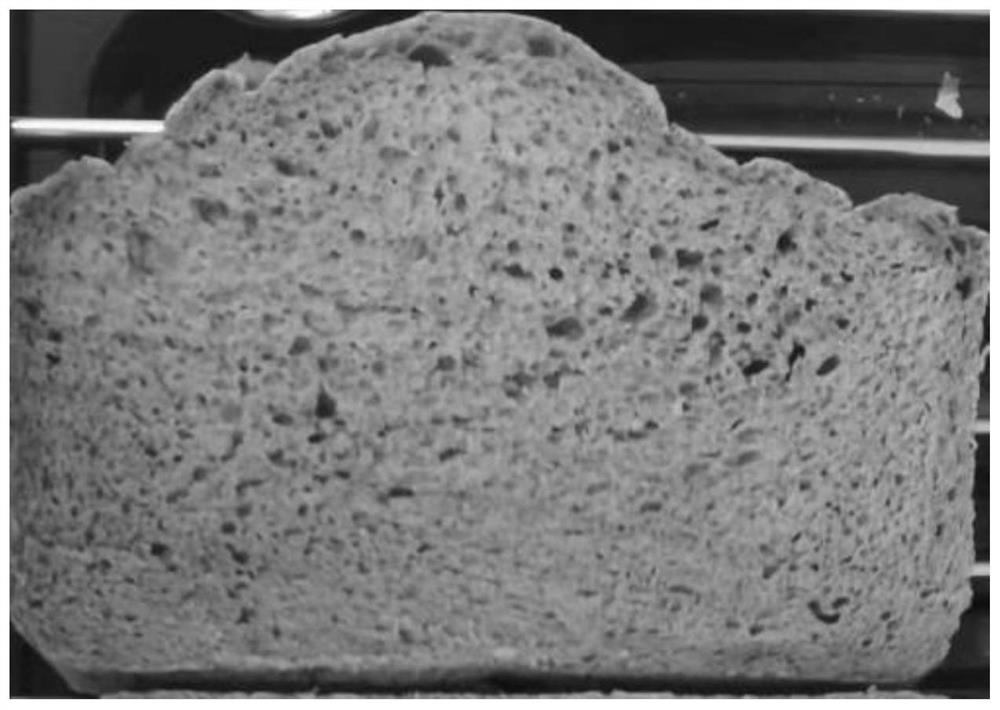

[0083] Example 3 (Catalog B#0713)

[0084] Add high grain dietary fiber staple food reconstituted bread mix to the bread machine. The formula of the high grain dietary fiber staple food reconstituted bread premix of this embodiment after adding dry yeast is: 90 parts of wheat bran, 38 parts of rice bran, 110 parts of vegetable protein, 24 parts of resistant dextrin, 5 parts of dry yeast, edible 3 parts of salt, 0.2 parts of mogroside.

[0085] Start the bread machine program, the specific parameters are designed as:

[0086] (1) Automatic water addition: 245 parts by weight;

[0087] (2) Knead the dough: the time is 20 minutes, the temperature is normal temperature but not higher than 30°C;

[0088] (3) Fermentation: time 45 minutes, temperature about 37°C;

[0089] (4) Baking: the time is 45 minutes, and the temperature is about 160°C.

[0090] After the prepared bread is sliced, it can be seen that there are obvious and relatively uniform holes, and the bread is soft as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com