Single-sided color steel inorganic silicon crystal smoke prevention and exhaust air duct plate and manufacturing method thereof

A production method and inorganic silicon technology, applied in chemical instruments and methods, vertical pipelines, layered products, etc., can solve the problems of composite bonding effect affecting product quality, limiting the application and promotion of single-sided composite panels, etc., to achieve excellent Fire resistance, fast curing, high viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

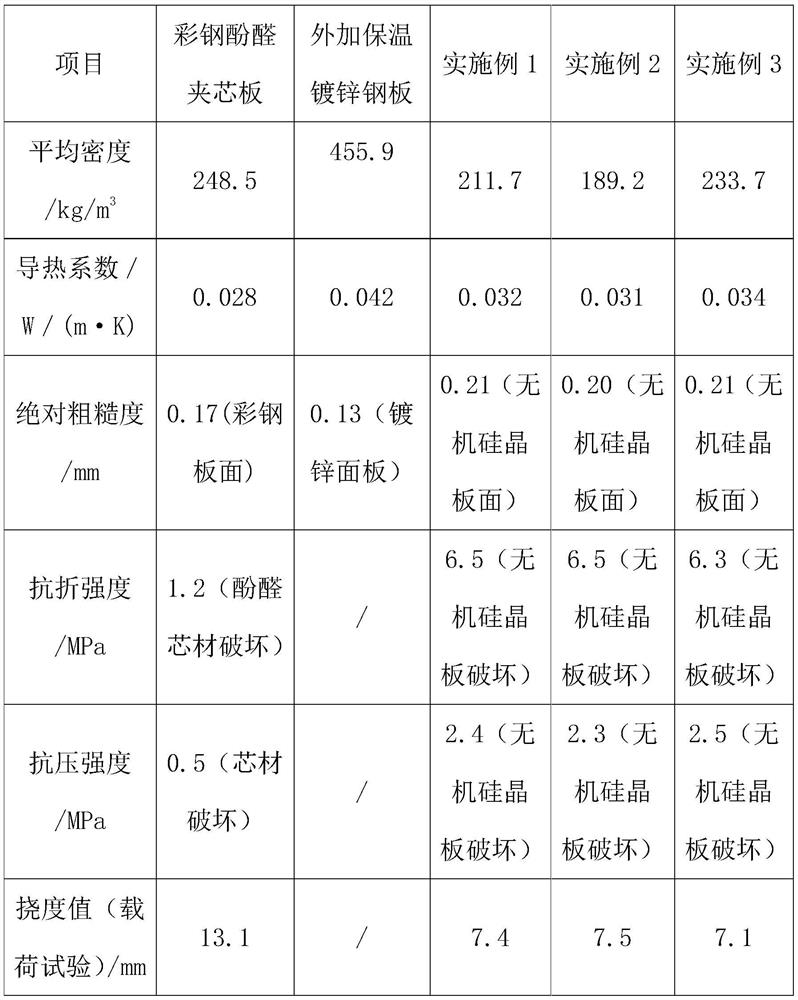

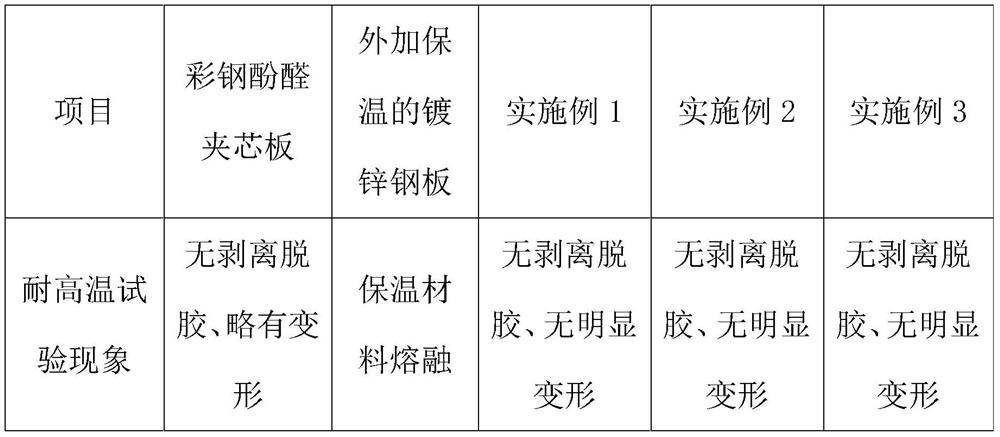

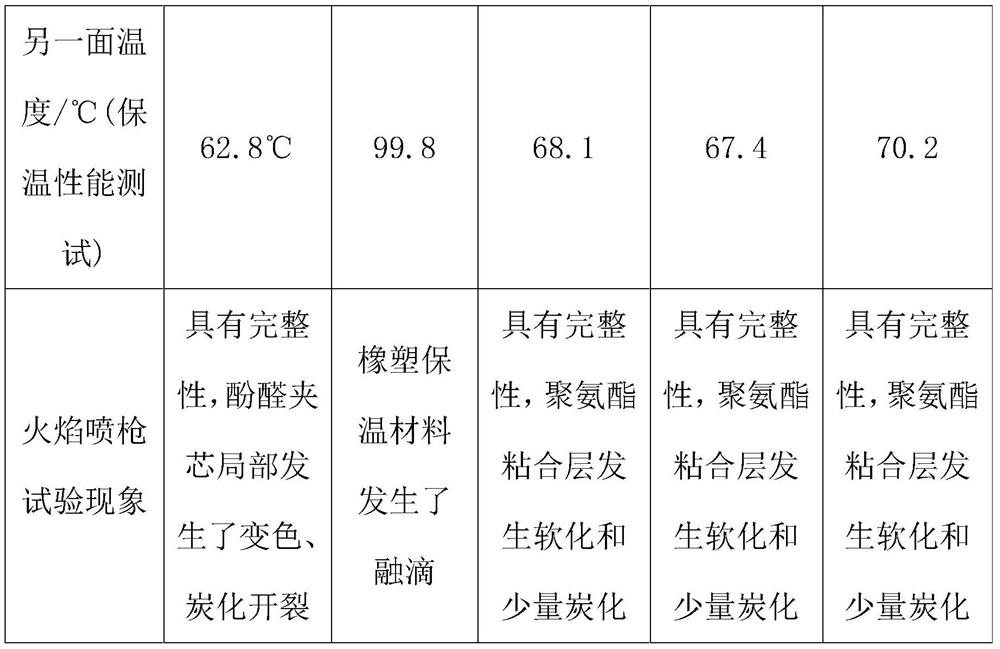

Embodiment 1

[0021] The single-sided color steel inorganic silicon crystal anti-smoke exhaust air duct plate of this embodiment includes a 0.3mm thick outer color steel plate, an 18mm thick inner inorganic silicon crystal plate and a 5mm thick middle layer of flame-retardant polyurethane gel. The layers are bonded through the middle layer, and the flame retardant components of the flame retardant polyurethane gel are trichloroethyl phosphate and aluminum hydroxide.

[0022] The density of the inorganic silicon crystal board used for the inner layer is 135kg / m 3 , is a heat-insulating ultra-light inorganic silicon crystal plate, which is a microcrystalline slurry generated by hydrothermal reaction after mixing high-purity silicon and calcium raw materials with inorganic fiber reinforcement materials, and then pressed into shape, steamed Made by pressure curing. The flame retardant polyurethane gel of the middle layer is obtained by mixing and curing component A and component B. Component A...

Embodiment 2

[0027] The single-sided color steel inorganic silicon crystal anti-smoke exhaust air duct plate of this embodiment includes a 0.25mm thick outer color steel plate, a 20mm thick inner inorganic silicon crystal plate, and a 4mm thick middle layer of flame-retardant polyurethane gel. The layers are bonded through the middle layer, and the flame retardant components of the flame retardant polyurethane gel are trichloroethyl phosphate and aluminum hydroxide.

[0028] The density of the inorganic silicon crystal board used for the inner layer is 125kg / m 3 , is a heat-insulating ultra-light inorganic silicon crystal plate, which is a microcrystalline slurry generated by hydrothermal reaction after mixing high-purity silicon and calcium raw materials with inorganic fiber reinforcement materials, and then pressed into shape, steamed Made by pressure curing. The flame retardant polyurethane gel of the middle layer is obtained by mixing and curing component A and component B. Component ...

Embodiment 3

[0032] The single-sided color steel inorganic silicon crystal anti-smoke exhaust air duct plate of this embodiment includes a 0.35mm thick outer layer color steel plate, a 16mm thick inner layer inorganic silicon crystal plate and a 6mm thick middle layer of flame retardant polyurethane gel. The layers are bonded through the middle layer, and the flame retardant components of the flame retardant polyurethane gel are trichloroethyl phosphate and aluminum hydroxide.

[0033] The density of the inorganic silicon crystal board used for the inner layer is 145kg / m 3 , is a heat-insulating ultra-light inorganic silicon crystal plate, which is a microcrystalline slurry generated by hydrothermal reaction after mixing high-purity silicon and calcium raw materials with inorganic fiber reinforcement materials, and then pressed into shape, steamed Made by pressure curing. The flame retardant polyurethane gel of the middle layer is obtained by mixing and curing component A and component B....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com