Spinnable down and blent down-silk material and their processing method

A processing method and a technology of mixing materials, which are applied in the direction of fiber mixing, textile and paper making, fiber treatment, etc., can solve problems such as inability to spin processing, limit the application range of velvet and feather, and achieve good hygroscopicity and heat preservation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

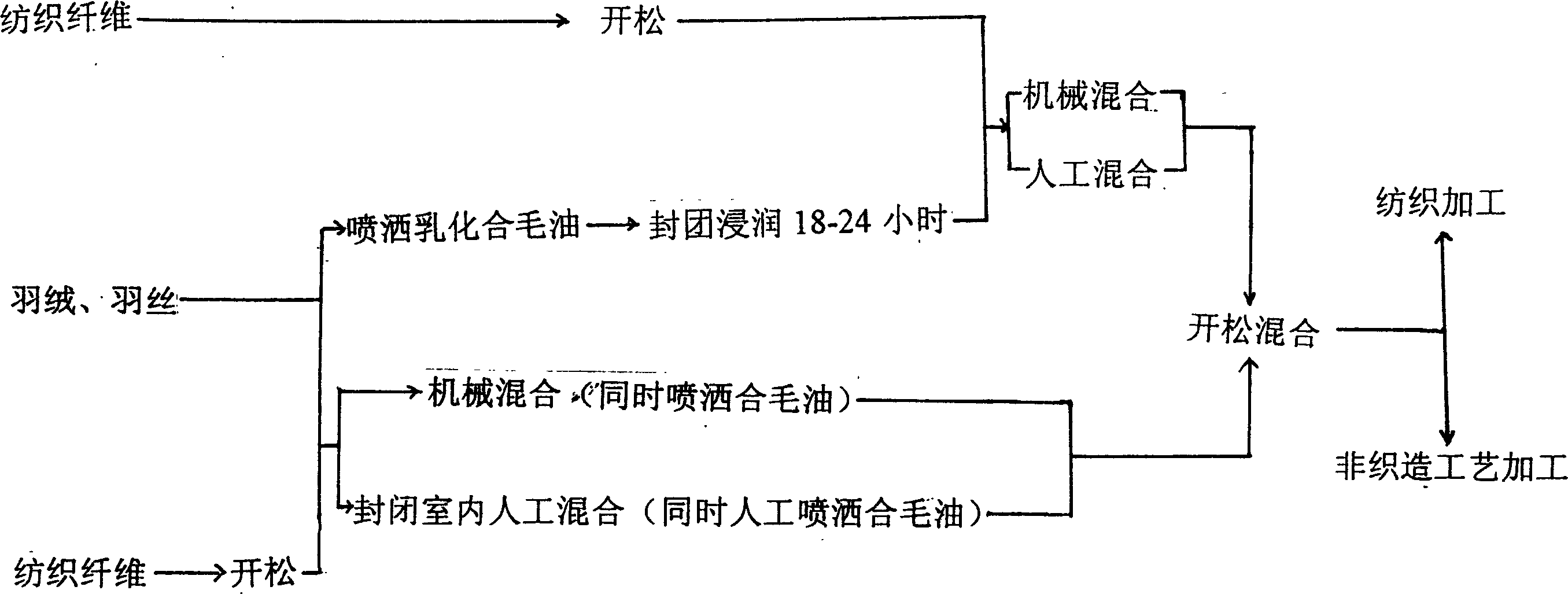

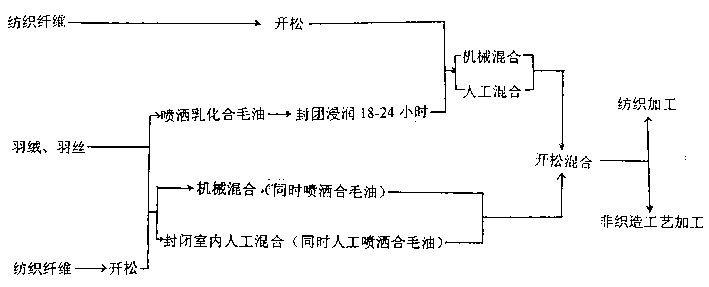

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: get velvet 50%, superfine chemical fiber 50%, set the grammage to be 200 / M 2 , the velvet and the opened microfiber are fed into the mixer according to the above-mentioned process and mixed, and then are opened, carded, mechanically disordered into a net, and consolidated by radial spunlace or acupuncture consolidation to form velvet Superfine fiber two-in-one non-woven fabric, this invention forms suede-like warm-keeping new fabric with unique advantages through suede-like finishing and processing, which can be used to make high-end warm-keeping fashions.

Embodiment 2

[0013] Example 2: 80% cashmere silk, 20% cashmere fiber, the cashmere silk and the opened cashmere fiber are fed into the mixer according to the described process and mixed, and then opened, carded, and air-laid. It is formed into a net and consolidated by acupuncture consolidation to form a thermal clothing lining with high cashmere content. This invention has the advantages of lightness, breathability, moisture absorption, and extremely low heat conduction. It is a poor conductor of heat clothing material.

Embodiment 3

[0014] Embodiment 3: Feather silk 70%, cashmere 30%, the cashmere fiber that feather silk and the opening are fed into the mixing machine according to the described process and mixed, and then through opening, carding, mechanical messy netting, through needle-punching The natural feather silk synthetic leather base fabric is formed by knotting. Because the air in the feather silk is large, the soft burrs on the surface of the feather silk are many and long, and the material formed has a large static air content, good hygroscopicity, and strong thermal insulation performance. All kinds of shoe leather and clothing leather made by the dry or wet synthetic leather processing technology in the existing technology not only have the moisture absorption and air permeability of natural leather, but also have special features such as warmth retention and lightness that natural leather does not have. performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com