Full-automatic reinforcing mesh welding machine

A fully automatic welding and steel mesh technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large space occupation, high labor intensity, trouble, etc., to reduce position error, avoid position interference, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

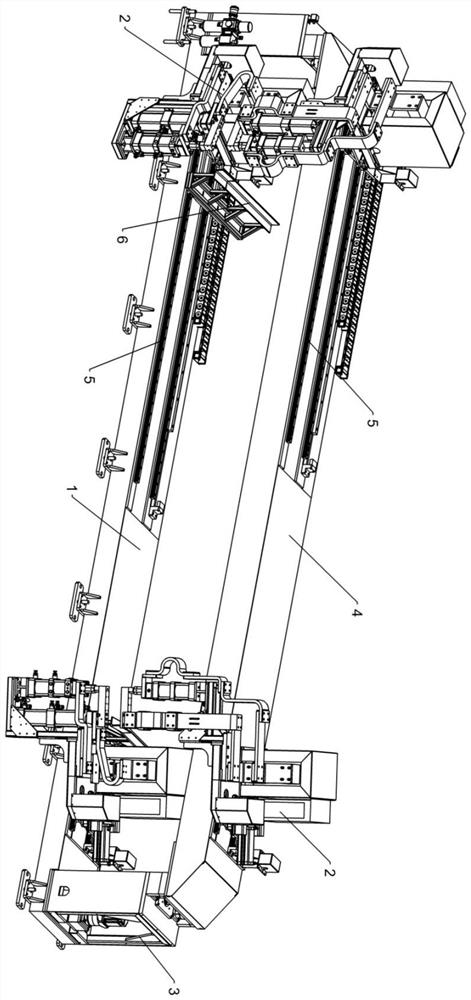

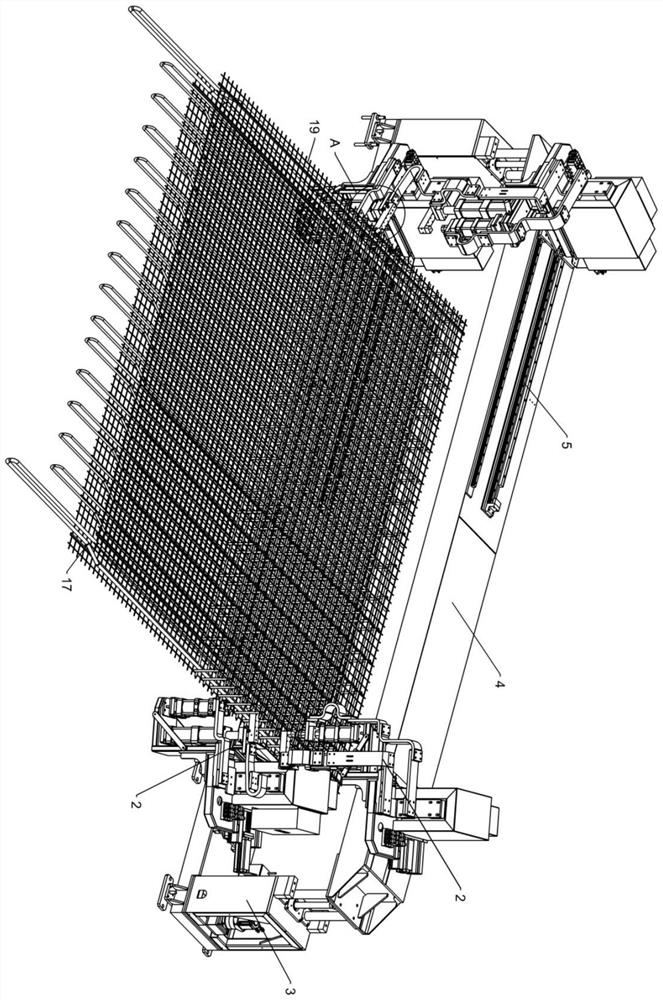

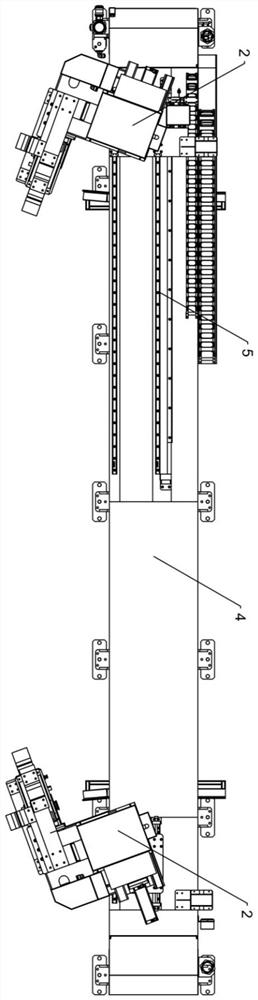

[0036] like Figure 1 to Figure 15 As shown, a fully automatic welding machine for steel mesh includes a lower frame 1, a mesh welding mechanism 2, a lifting assembly 3, an upper frame 4, an X-direction moving assembly 5, a support frame 6, a bottom inclined plate 201, an installation Plate 202, transformer 203, upper electrode assembly 204, lower electrode assembly 205, mounting frame 206, upper electrode assembly 204, hard copper bar 1 2041, soft copper bar 1 2042, upper welding head 2043, hard copper bar 2 2044, upper electrode Cylinder 2045, hard copper row 3 2051, soft copper row 2 2052, lower welding head 2053, hard copper row 4 2054, lower electrode cylinder 2055, lifting frame 301, electric cylinder 302, guide rod 303, linear bearing 304, guide plate 305 , output shaft 306, upper insulating gasket 7, avoidance hole 8, insulating hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com