Bolt torque detection device

A technology for torque detection and bolts, which is applied in the field of bolt torque detection devices, can solve problems such as inconvenient carrying, heavy weight, and impact on detection efficiency, so as to improve the range of position and angle adjustment, ensure flexibility, and reduce the risk of personal injury Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

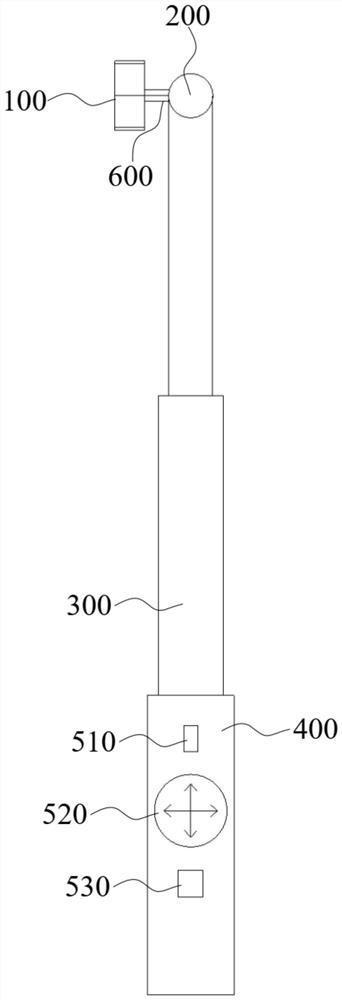

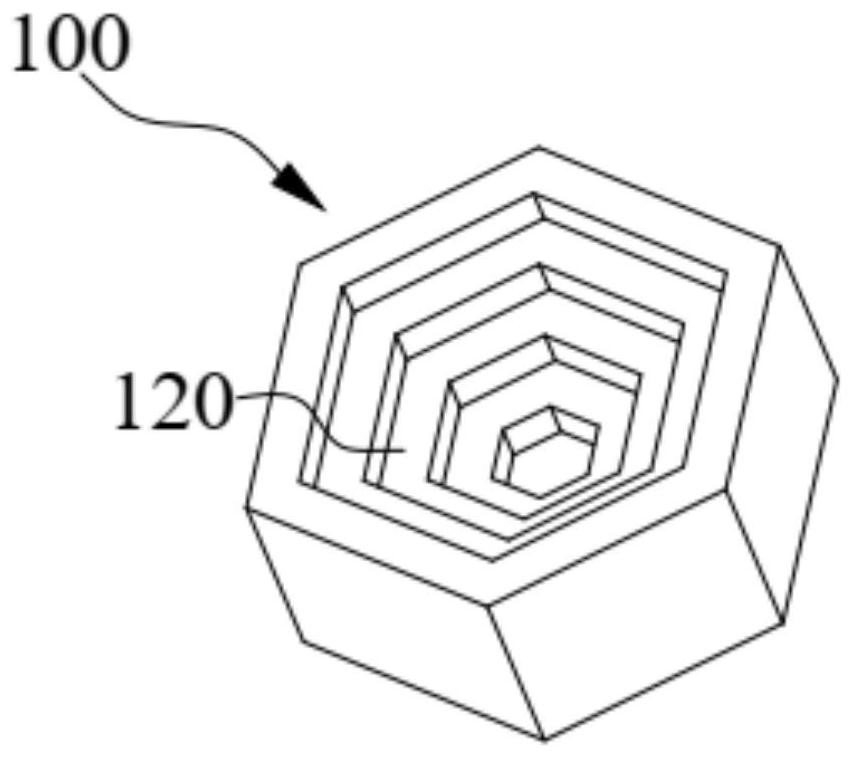

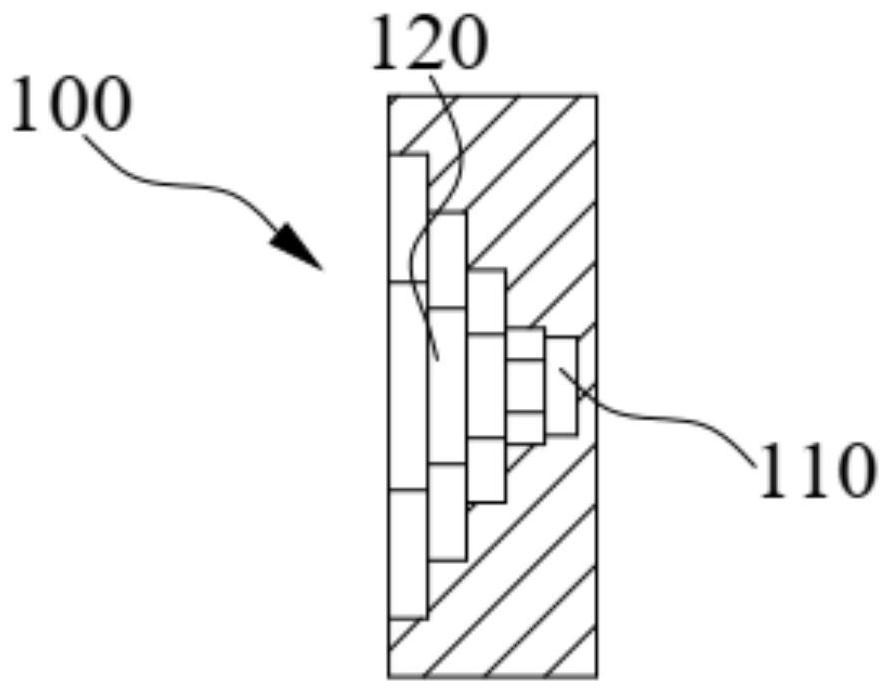

[0030] Such as Figure 1-Figure 3 As shown, the present embodiment provides a bolt torque detection device for testing the fastening performance of bolts, including a positioning fixture 100, a handle part 400 and a control panel; the positioning fixture 100 is a cylindrical part, and the positioning fixture 100 One side of the limit groove is provided with a limit groove, which can be sleeved on the nut of the bolt, and the bottom of the limit groove is also provided with an adsorption piece 110, which is used to absorb the bolt; the handle piece 400 is connected to the multi-stage telescopic rod 300 At one end, the end of the multi-stage telescopic rod 300 away from the handle part 400 is rotationally connected with the side of the positioning fixture 100 that is not provided with a limit groove through a universal joint 200; the control panel is installed on the handle part 400, and the control panel can control the multi-stage telescopic rod 300 telescopic, the positioning...

Embodiment 2

[0044] Such as Figure 4 As shown, the bolt torque detection device of the second embodiment is basically the same as the first embodiment above, the difference between the two is that a plurality of abutting pieces 140 are arranged in the limiting groove, and the abutting pieces 140 can abut against the nuts. On the side, the abutment piece 140 is connected with a telescopic piece 130, and the telescopic piece 130 can drive the abutment piece 140 to approach or move away from the middle of the limiting groove. The arrangement of the abutting piece 140 ensures that the positioning fixture 100 can be widely used in the detection of various sizes and types of bolts, thereby greatly improving the detection efficiency.

[0045] Specifically, the positioning jig 100 further includes a third driving unit, the third driving unit is used to drive the telescopic member 130 to expand or contract, and the third driving unit is disposed in the positioning jig 100 .

[0046] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com