A diaphragm quality detection device and method thereof

A detection device and detection method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low detection efficiency of diaphragm thickness detectors, low efficiency of diaphragm quality detection, and inaccurate detection results, etc., and achieve reduction Difficulty in data processing, fast measurement speed, strong representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

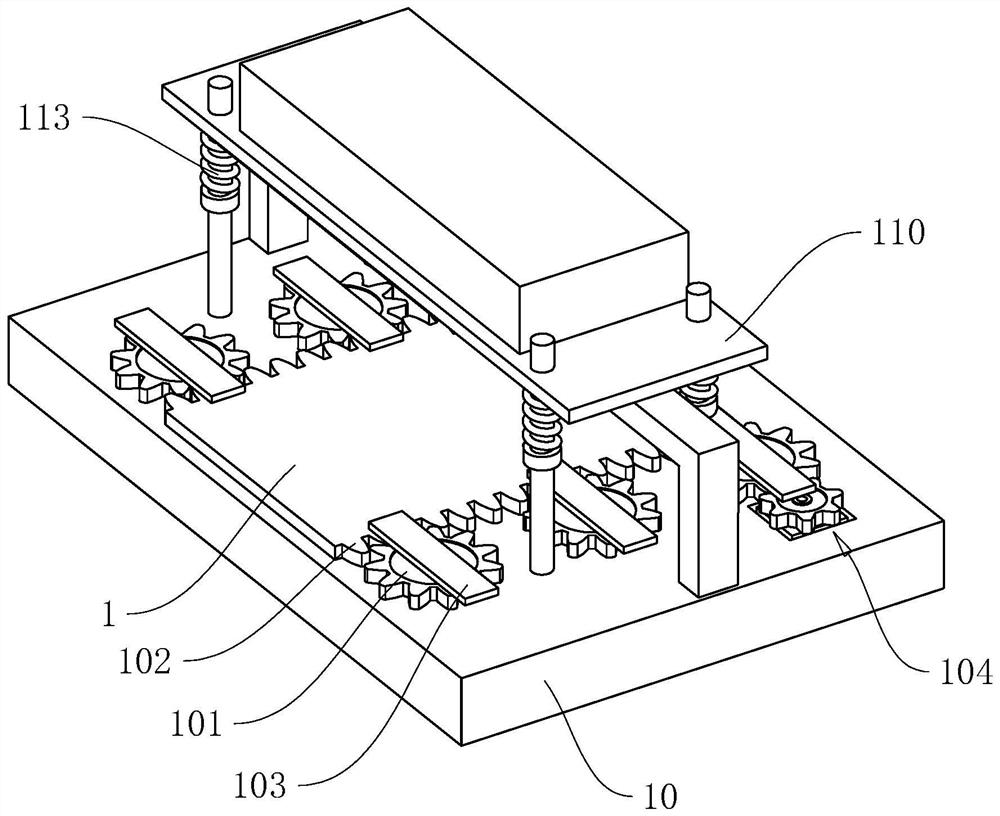

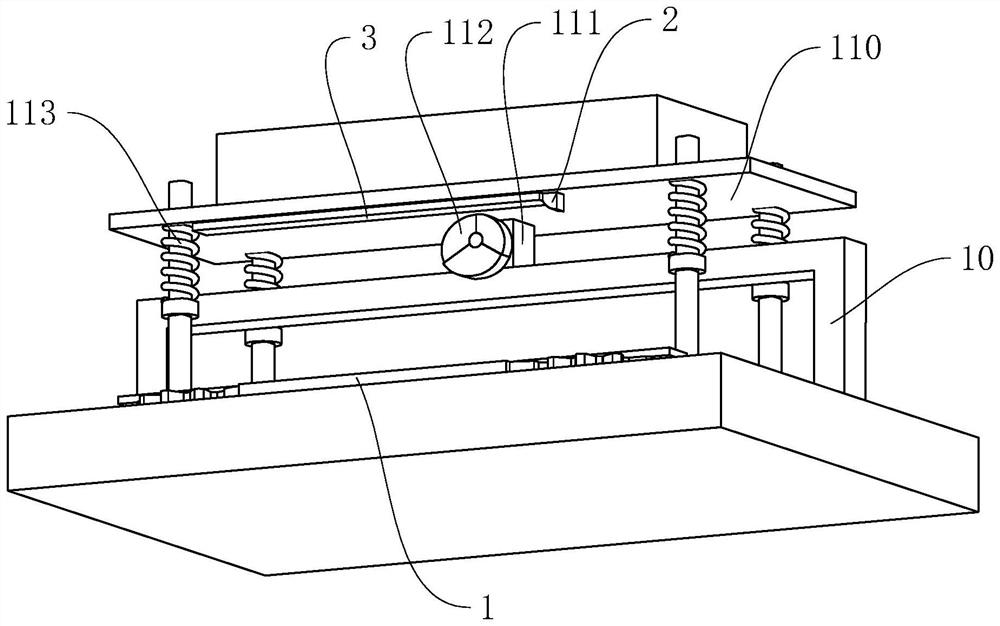

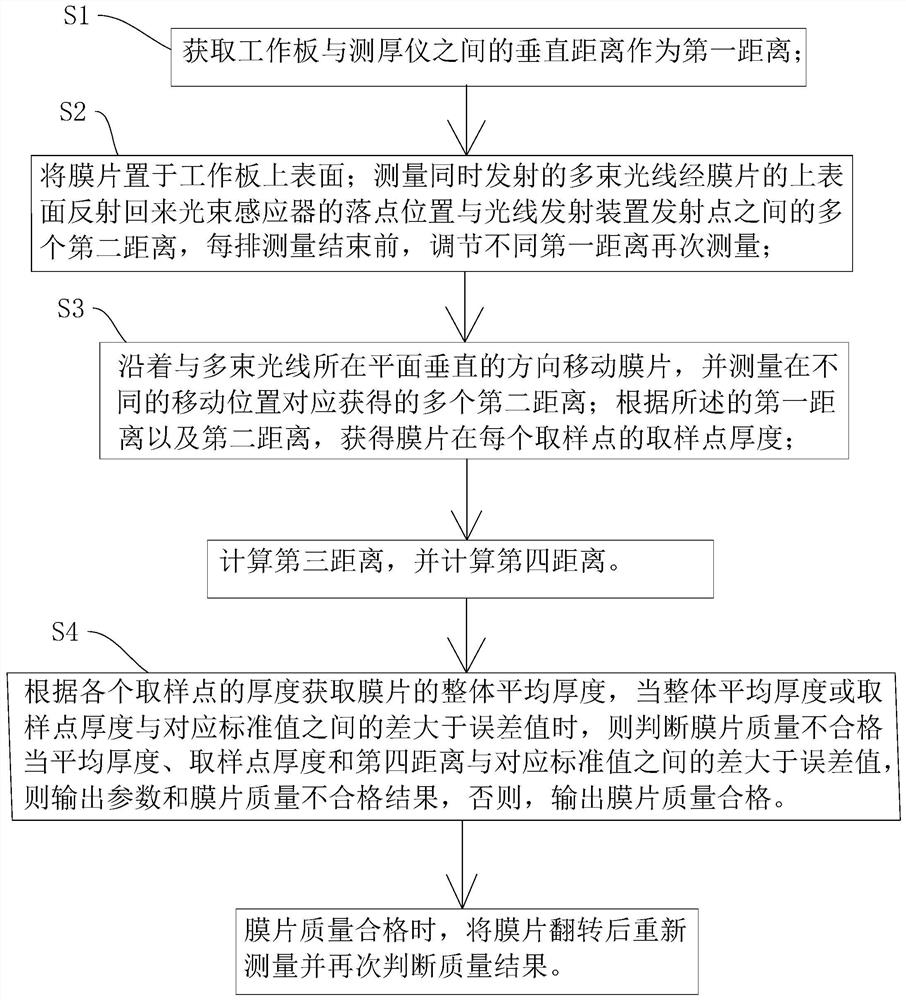

[0054] refer to figure 1 with figure 2 The diaphragm quality detection device includes a frame 10 on which a working plate 1 is slidably installed, and a thickness gauge is installed on the top of the frame 10, and the thickness gauge can measure the thickness of an object placed on the working plate 1. The thickness gauge includes a light emitting device 2, a light sensing device 3 and a data processing system.

[0055] The light emitting device 2 is arranged on one side of the frame 10. The emitting end of the light emitting device 2 faces the working board 1, and can emit a plurality of light beams that are on the same plane and have different angles from the upper surface of the working board 1 against the working board 1. Light, the light sensing device 3 and the light emitting device 2 are arranged side by side along the sliding direction perpendicular to the working plate 1 .

[0056] The emitting end of the light emitting device 2 and the receiving end of the light ...

Embodiment 2

[0088] The difference between this embodiment and Embodiment 1 is that in order to improve the measurement accuracy, step S2 also includes: after the measurement of each row of sampling points is completed, the first distance L is adjusted by changing the overall height of the thickness gauge. In this embodiment, the first distance L is adjusted by adjusting the height of the thickness gauge twice, so that after the measurement of each row of sampling points is completed, three sets of sampling points for each row of sampling points are calculated by changing the first distance L twice. Point thickness X, and then calculate the average sampling point thickness of each row of sampling points through the average

[0089] Then the overall average thickness X of the diaphragm:

[0090]

[0091] in,

[0092] By setting multiple sets of data of the first distance L, measurement errors can be reduced, the accuracy of diaphragm thickness data measurement can be improved, and the...

Embodiment 3

[0094] The difference between this embodiment and other embodiments is that it also includes the following steps:

[0095] After step S3 is completed, the data processing system calculates the light corresponding to each sampling point in the light sensing device 3 according to the overall average thickness X, the acute angle θ formed by the corresponding light and the vertical line, and the first distance L through mathematical geometric relations. The third distance P between the theoretical landing point on the above and the emission point of the light emitting device 2; according to the third distance P and each sampling point corresponding to the second distance N, the fourth distance G is calculated through the difference, specifically through the following formula calculate:

[0096]

[0097] Among them, P i-k =2(L i-k -X)tanθ;

[0098] if there is G 3 If it is greater than the preset value, it is judged that the quality of the diaphragm is unqualified.

[0099]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com