Method for filling aerosol generating product and aerosol generating product prepared thereby

An aerosol generation and product technology, which is applied in the manufacture of cigarettes, cigars, smoke oil filters, etc., can solve the problems of pipe pollution, material waste, and large loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example is the preparation of sample 1 of the aerosol generating product.

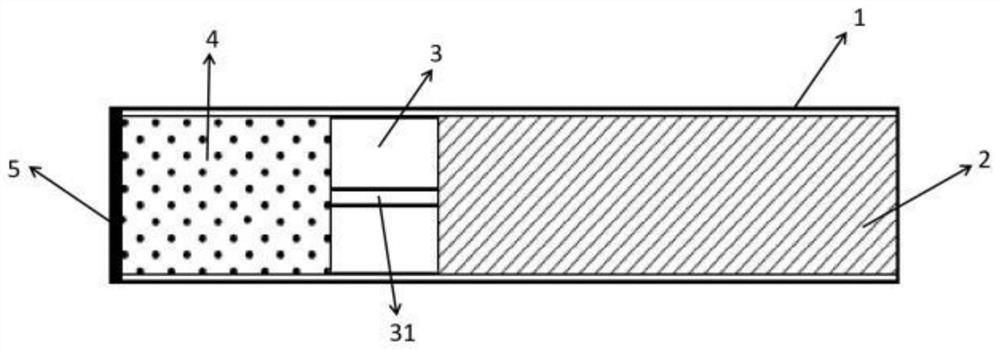

[0046] Such as figure 1 , the aerosol generating product sample 1 includes a tube body 1, a filter component 2 arranged in sequence from the proximal lip end to the distal lip end in the tube body 1, a blocking flow guide component 3, a smoke unit 4, and a tube body 1 located on the far lip The sealing member 5 of the end face.

[0047] The filling method of aerosol generating product sample 1 comprises the following steps ( Figure 6 ): (1) prepare the tube body 1 of the aerosol generating product; (2) fill the filter component 2 in the tube body 1, and the filter component 2 is close to the near-lip end surface of the tube body 1; (3) Install the barrier flow guide part 3 from the far lip end of the tube body 1, and the barrier flow guide part 3 is close to the filter part 2; (4) install the smoking unit 4 from the far lip end of the tube body 1, so that The smoking unit 4 is located ...

Embodiment 2

[0050] This example is the preparation of sample 2 of the aerosol generating product.

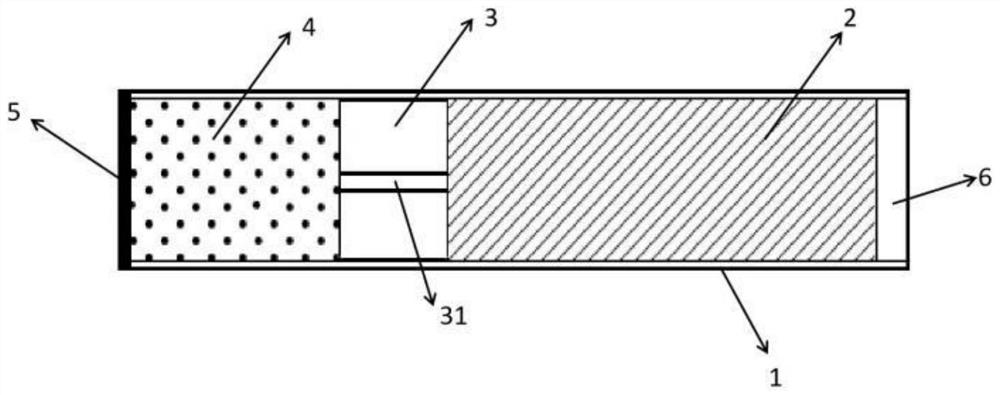

[0051] Such as figure 2 , the aerosol generating product sample 2 includes a tube body 1, a settling unit 6, a filter component 2, a barrier flow guide component 3, a smoke unit 4, and a settling unit located in the tube body 1 arranged in sequence from the near lip end to the far lip end, and the The sealing member 5 on the end face of the far lip end of the body 1.

[0052] The filling method of the sample 2 of the aerosol generating product comprises the following steps: (1) preparing the tube body 1 of the aerosol generating product; (2) filling the filter part 2 in the tube body 1, and the filter part 2 is close to the tube The near lip end of the body 1; a certain cavity is left between the filter part 2 and the near lip end face of the tube body 1, and this cavity is the settling unit 6; (3) from the tube body 1 The far lip end is loaded into the blocking and guiding part 3, and t...

Embodiment 3

[0055] This example is the preparation of sample 3 of the aerosol generating product.

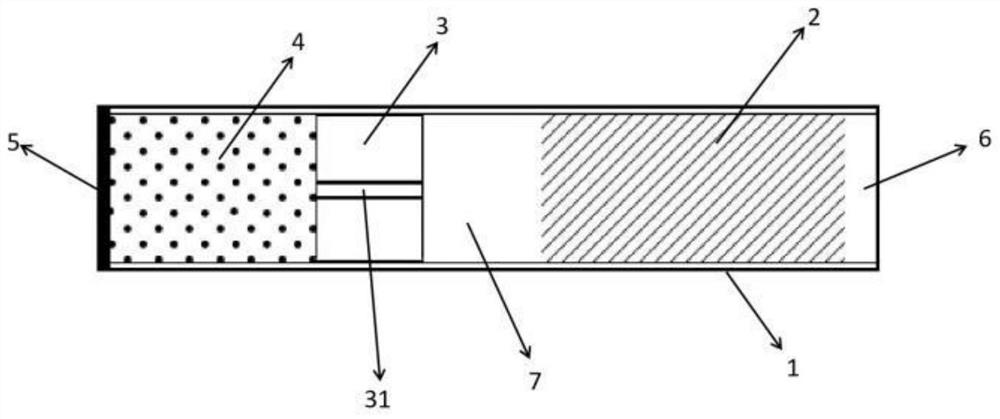

[0056] Such as image 3 The aerosol generating product sample 3 includes a tube body 1, a settling unit 6, a filter component 2, a functional unit 7 in the form of a cavity, a barrier flow guiding component 3, The smoking unit 4, and the sealing member 5 located on the end surface of the distal lip end of the tube body 1.

[0057] The filling method of the aerosol generating product sample 3 comprises the following steps: (1) preparing the tube body 1 of the aerosol generating product; (2) filling the filter part 2 in the tube body 1, and the filter part 2 is close to the tube Near the lip end of the body 1, there is a certain cavity between the filter part 2 and the near lip end face of the tube body 1, and this cavity is the settling unit 6; (3) from the tube body 1 The far lip end is packed into the blocking flow guiding part 3, but there is a section of cavity between the blocking flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com