Mask group, evaporation device and method for monitoring thicknesses of functional layers of light-emitting device

A technology for light-emitting devices and functional layers, which is applied to the monitoring of the thickness of the functional layer of the vapor deposition device and the light-emitting device, and the field of mask sets. time, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be clearly and completely described through implementation with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are the embodiment of the present invention. Some, but not all, embodiments. All other embodiments obtained by those skilled in the art based on the basic concepts disclosed and suggested by the embodiments of the present invention belong to the protection scope of the present invention.

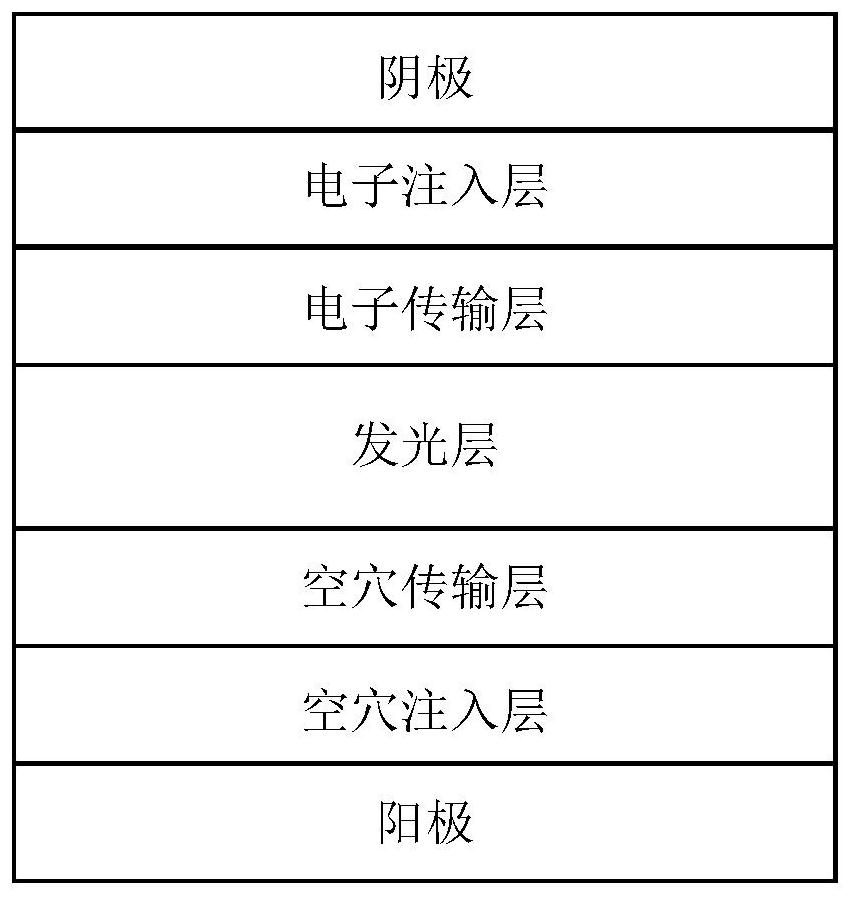

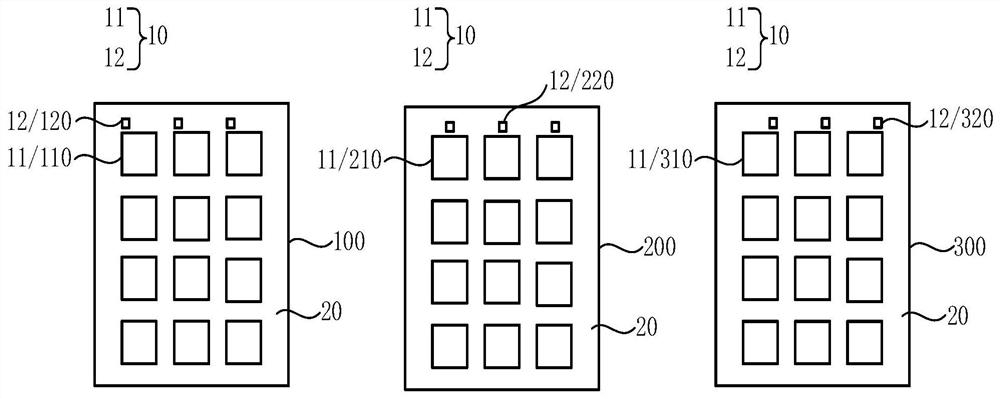

[0041] In the current OLED industry, Fine Metal Mask (FMM) technology is usually used to regionalize and pattern the evaporation material. During the evaporation process, a fixed mask and a moving substrate are used to evaporate Plated luminescent devices. figure 1 is a schematic structural diagram of a light emitting device provided by an embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com