Novel efficient energy-saving wastewater treatment device and use method thereof

A high-efficiency, energy-saving, wastewater treatment technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. The effect of sludge reduction, not easy to block, easy to clean and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

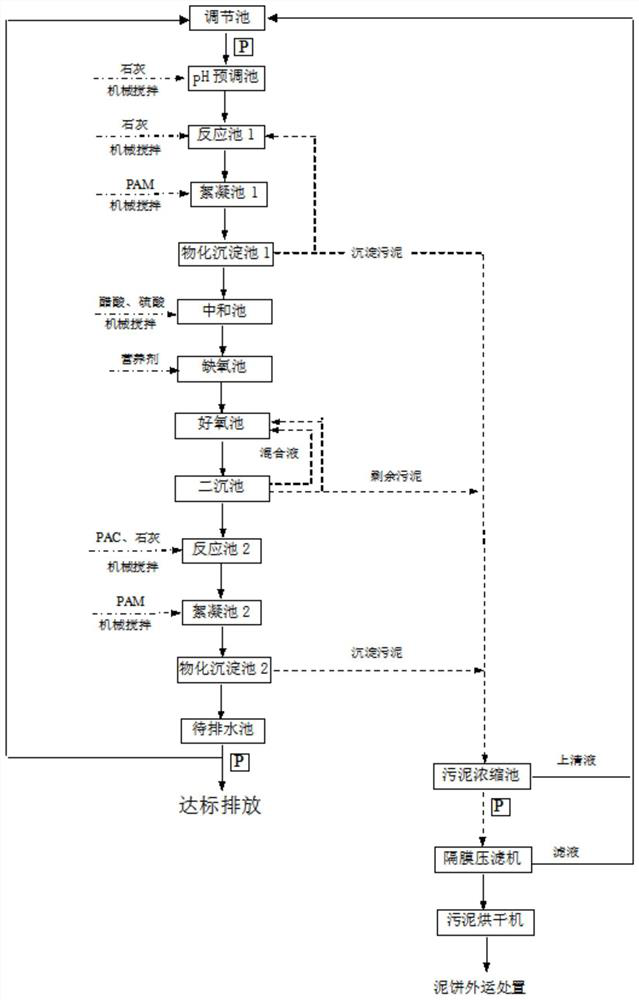

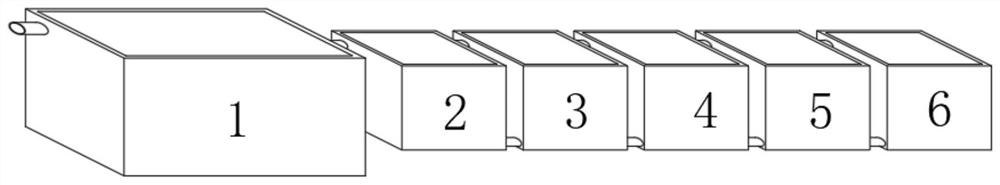

Embodiment 1

[0034] Such as Figure 1-6 As shown, a new high-efficiency and energy-saving wastewater treatment device includes a wastewater storage tank 1, one end of the wastewater storage tank 1 is connected to a regulating tank body 2, and one end of the regulating tank body 2 is connected to a pH pre-adjusting tank body 3, and the pH pre-adjusting tank One end of the body 3 is connected with a No. 1 reaction pool 4, one end of the No. 1 reaction pool 4 is connected with a No. flocculation pool 5, one end of the No. 1 flocculation pool 5 is connected with a No. 1 physicochemical sedimentation pool 6, and one end of the No. 1 physicochemical sedimentation pool 6 is connected with a The neutralization tank body 11 is connected with the sludge thickening tank 16, and one end of the neutralization tank body 11 is connected with the anoxic tank body 10, and one end of the anoxic tank body 10 is connected with the aerobic tank body 9, and one end of the aerobic tank body 9 is connected with T...

Embodiment 2

[0045] On the basis of Example 1, as Figure 1-6 As shown, a new high-efficiency and energy-saving wastewater treatment device includes a wastewater storage tank 1, one end of the wastewater storage tank 1 is connected to a regulating tank body 2, and one end of the regulating tank body 2 is connected to a pH pre-adjusting tank body 3, and the pH pre-adjusting tank One end of the body 3 is connected with a No. 1 reaction pool 4, one end of the No. 1 reaction pool 4 is connected with a No. flocculation pool 5, one end of the No. 1 flocculation pool 5 is connected with a No. 1 physicochemical sedimentation pool 6, and one end of the No. 1 physicochemical sedimentation pool 6 is connected with a The neutralization tank body 11 and the sludge thickening tank 16, one end of the neutralization tank body 11 is connected with the anoxic tank body 10, one end of the anoxic tank body 10 is connected with the aerobic tank body 9, and one end of the aerobic tank body 9 is connected with T...

Embodiment 3

[0056] On the basis of Example 2, such as Figure 1-6 As shown, a new high-efficiency and energy-saving wastewater treatment device includes a wastewater storage tank 1, one end of the wastewater storage tank 1 is connected to a regulating tank body 2, and one end of the regulating tank body 2 is connected to a pH pre-adjusting tank body 3, and the pH pre-adjusting tank One end of the body 3 is connected with a No. 1 reaction pool 4, one end of the No. 1 reaction pool 4 is connected with a No. flocculation pool 5, one end of the No. 1 flocculation pool 5 is connected with a No. 1 physicochemical sedimentation pool 6, and one end of the No. 1 physicochemical sedimentation pool 6 is connected with a The neutralization tank body 11 and the sludge thickening tank 16, one end of the neutralization tank body 11 is connected with the anoxic tank body 10, one end of the anoxic tank body 10 is connected with the aerobic tank body 9, and one end of the aerobic tank body 9 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com