Permeation type nano printing process for cloth production

A nano-printing and process technology, applied in the printing field, can solve the problems of poor visual effect and hand feeling, insufficient printing surface of printed matter, incomplete curing and drying, etc., and achieve the effect of delicate hand feeling, smooth printing surface and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

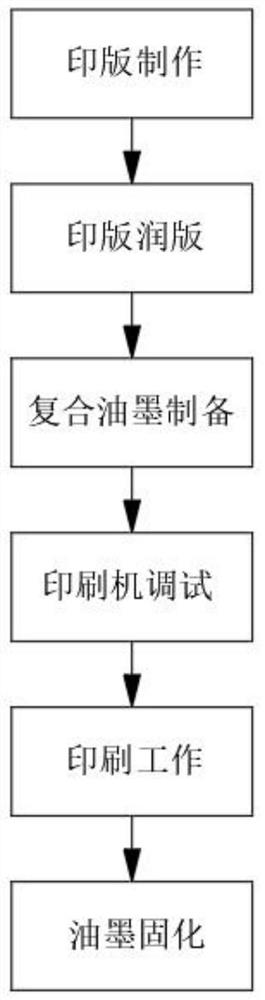

[0027] Such as figure 1 A permeable nano-printing process for cloth production as shown, comprising the following steps:

[0028] S1. Printing plate production, according to the specifications of the printed matter, the printing plate is processed by issuing, proofing, imposing, and printing;

[0029] S2, printing plate dampening, printing plate dampening treatment uses alcohol-free dampening solution, put the non-alcoholic dampening solution into the container, and then put the printing plate into the container for infiltration treatment, use drying after taking it out equipment for drying;

[0030] S3, preparation of composite ink, take an ink preparation barrel, add insect repellent material, pigment, episulfide resin, ethyl acetate, dicyandiamide, oleic acid glyceride, oxalic acid, Magnesium sulfate, protein powder, beeswax, auxiliary additives, dispersant, deionized water, stir the mixed solution in the ink preparation tank, or pour the mixed solution from the feed hopp...

Embodiment 2

[0035] Among them, the fountain solution has the following components by weight: 20-30 parts of peach gum, 20-30 parts of oxalic acid, 6-10 parts of auxiliary additives, 2-3 parts of zinc chloride, 3-5 parts of red agate powder , 7-8 parts of octylphenol polyoxyethylene ether, the composite ink includes the following components in parts by weight: 3-5 parts of insect repellent, 4-9 parts of pigment, 30-50 parts of episulfide resin, 3 parts of ethyl acetate -5 parts, 4-6 parts of dicyandiamide, 4-8 parts of glyceryl oleate, 1-4 parts of oxalic acid, 1-4 parts of magnesium sulfate, 3-7 parts of protein powder, 2-6 parts of beeswax, auxiliary additives 20-30 parts, 1-4 parts of dispersant, 70-80 parts of deionized water, mixing equipment is used in the production of composite ink, the mixing time of the mixing equipment is 8 minutes, the heating temperature is 60 ℃, and the UV curing lamp used The power is 8000 watts, the irradiation time is 3 seconds, the temperature environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com