Safe waste power battery discharge-free continuous crushing equipment

A technology for power batteries and crushing equipment, which is applied in the field of waste power battery discharge-free continuous crushing equipment, can solve problems such as hidden safety hazards, incomplete discharge, and fire, and achieve the effect of effective utilization, eliminating the discharge process and shortening the recycling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

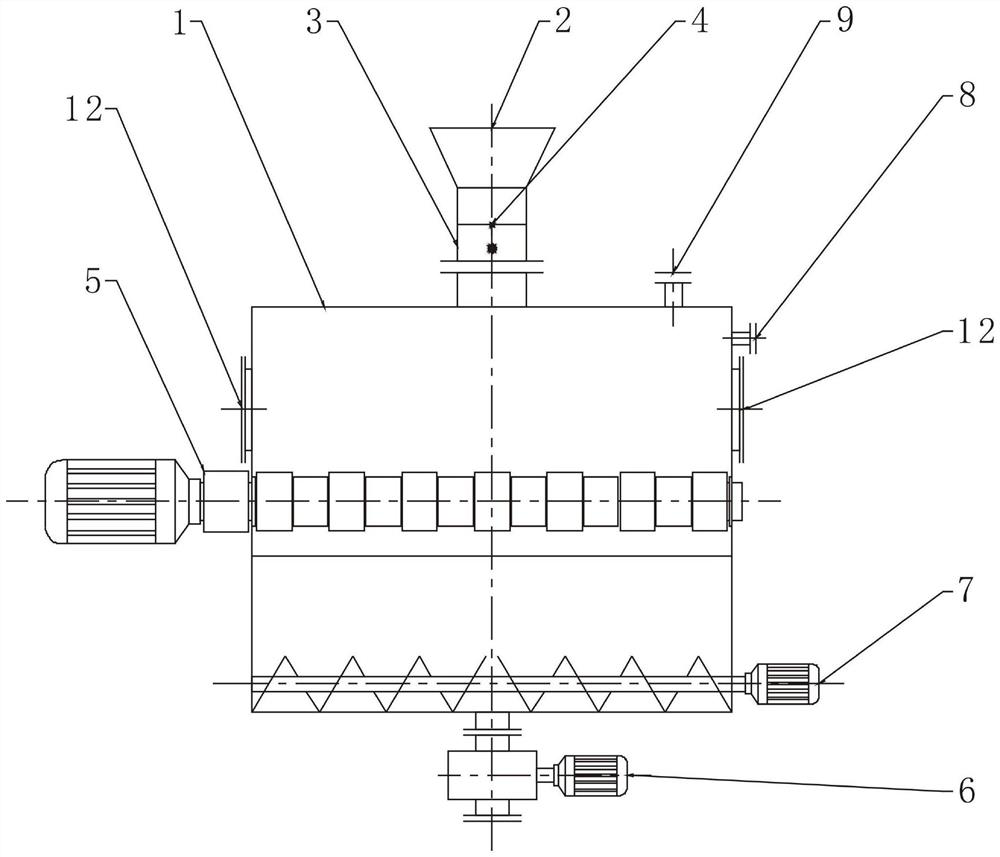

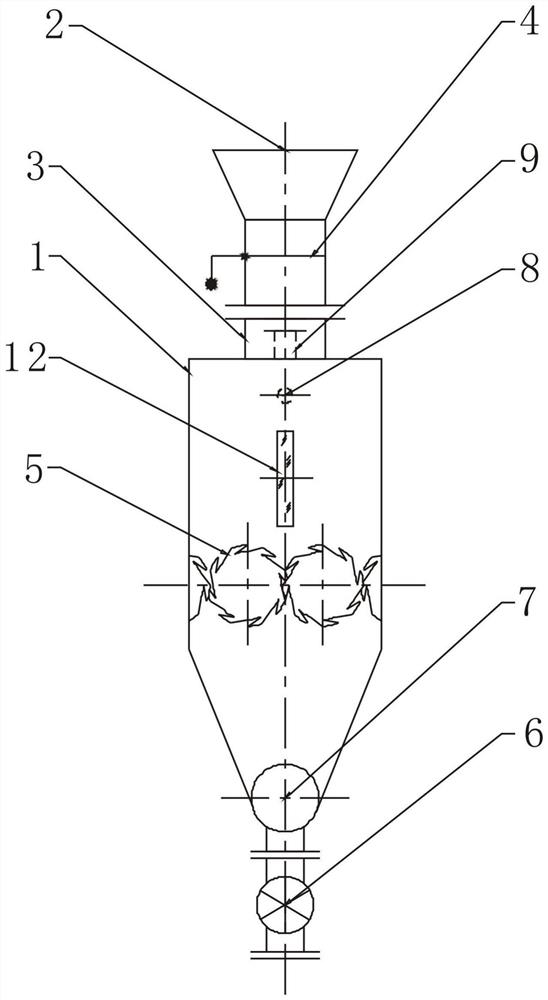

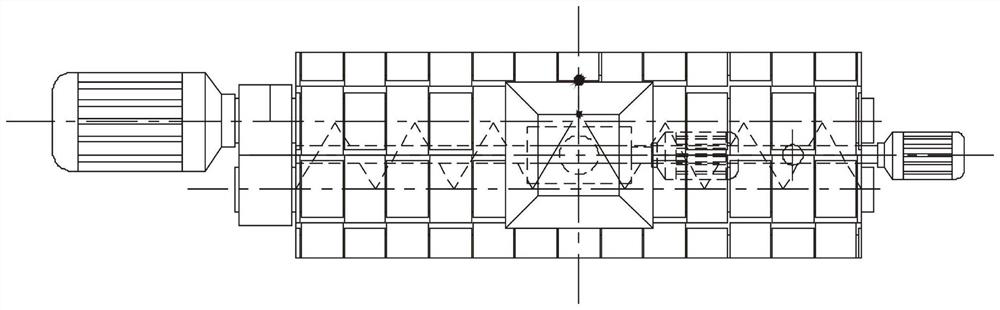

[0035] Such as Figure 1-Figure 3 As shown, a safe discharge-free continuous crushing device for waste power batteries of the present invention includes a crushing bin 1, and a feeding mechanism is provided on the top of the crushing bin 1, and the feeding mechanism includes a feeding hopper 2 located above, and a feeding hopper 2 The feed pipe 3 connected at the bottom, the feed hopper 2 is a conical feed hopper or a rectangular cone feed hopper for convenient feeding, the feed pipe 3 is fixed on the top of the crushing bin 1 and connected to the bottom of the crushing bin 1 The inner cavities are connected, and a heavy hammer flap valve 4 is set between the feed hopper 2 and the feed pipe 3 to seal the gas. The recovered waste power batteries are directly fed into the feed hopper 2, sealed and air-tight through the heavy hammer flap valve 4, and then fed into the crushing bin 1 through the feed pipe 3.

[0036] The crushing chamber 1 is provided with a crushing mechanism 5,...

Embodiment 2

[0052] The structure of a safe discharge-free continuous crushing equipment for waste power batteries in this embodiment is basically the same as that of Embodiment 1, the only difference is that in this embodiment, a row of sprinklers is arranged horizontally on the upper part of the inner cavity of the crushing bin 1. Mechanism 13, the inlet of spray mechanism 13 communicates with liquid inlet 8. When working, the equipment in this embodiment no longer allows the crushing mechanism 5 to be immersed in water, but uses the spray liquid method to take away the heat released by the battery discharge, which can also achieve the same effect as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com