Fabricated curtain wall natural ventilation energy-saving system

A technology of natural ventilation and energy-saving system, applied in the field of building decoration, can solve the problem of poor indoor air circulation effect, and achieve the effect of improving service life, convenient installation and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-5 The application is described in further detail.

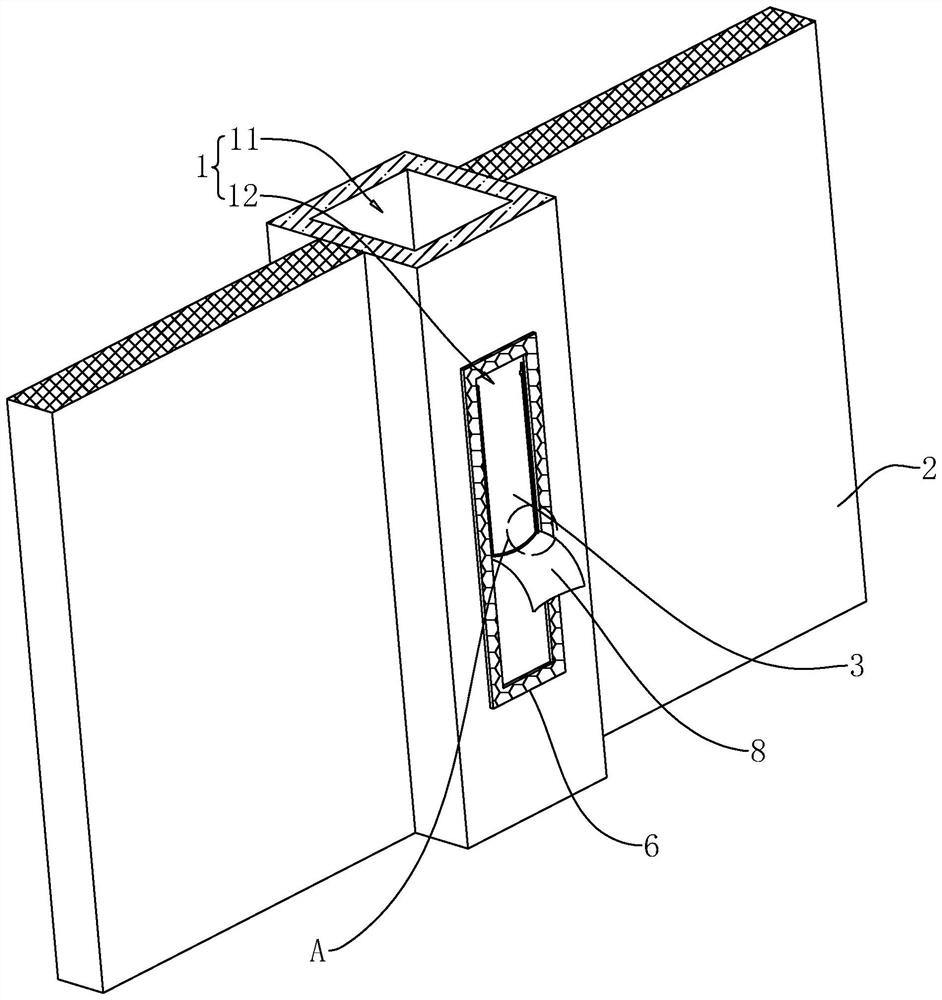

[0038] refer tofigure 1 , the prefabricated curtain wall mainly includes the keel 1 and the glass curtain wall panel 2. During the installation process, the operator first determines the installation position of the keel 1 on the periphery of the wall, then fixes the keel 1 on the periphery of the wall, and finally installs the glass curtain wall panel 2 Connecting with the keel 1, the periphery of the wall can be covered by the glass curtain wall plate 2.

[0039] The embodiment of the present application discloses an energy-saving natural ventilation system for a prefabricated curtain wall.

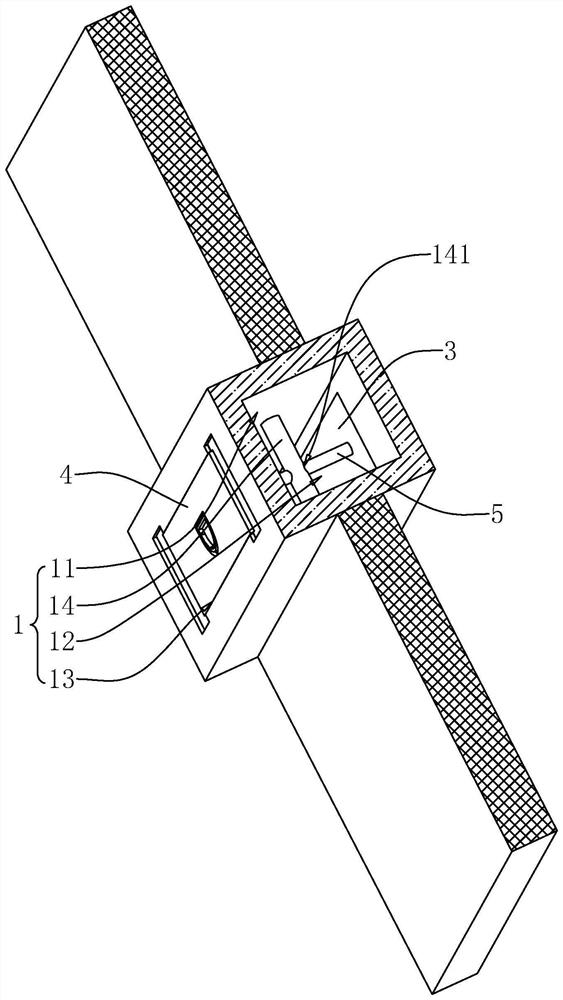

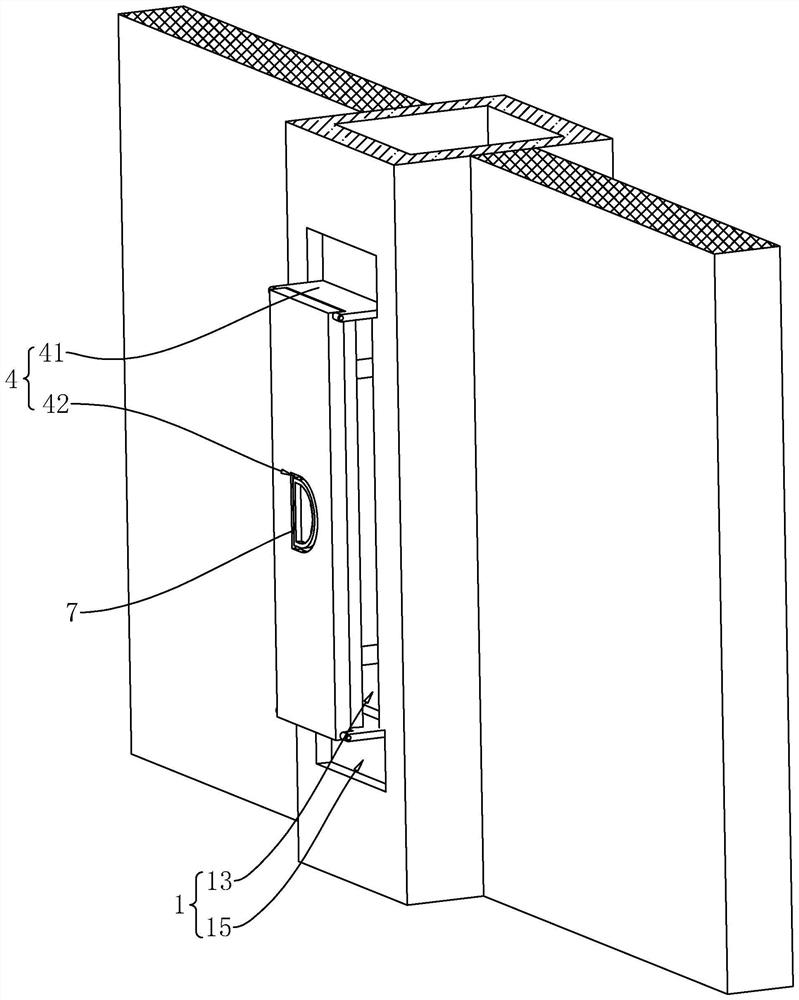

[0040] refer to figure 2 , a prefabricated curtain wall natural ventilation energy-saving system includes a keel 1, a windshield 3 and a shielding plate 4, wherein the keel 1 has a cavity 11, and the surfaces of the keel 1 away from each other are respectively provided with an air inlet 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com