An anti-collapse tunnel construction disaster prevention and mitigation structure

A tunnel construction and anti-collapse technology, which is applied in the direction of fire prevention, dust prevention, and supporting the top beam of the mine roof. It can solve the problems that the tunnel wall cannot be supported, the support angle cannot be adjusted, and the construction personnel cannot be notified when the deployment mechanism is adjusted. , to achieve the effect of expanding the support protection area, increasing the overall safety space, and expanding the protection angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

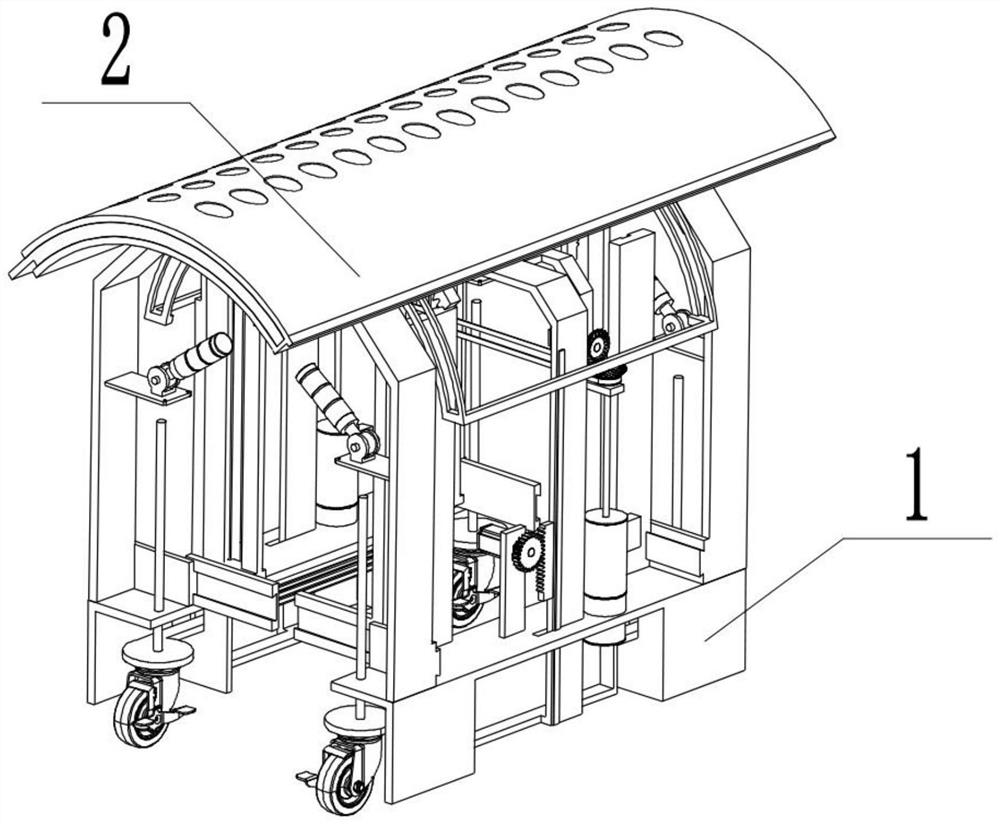

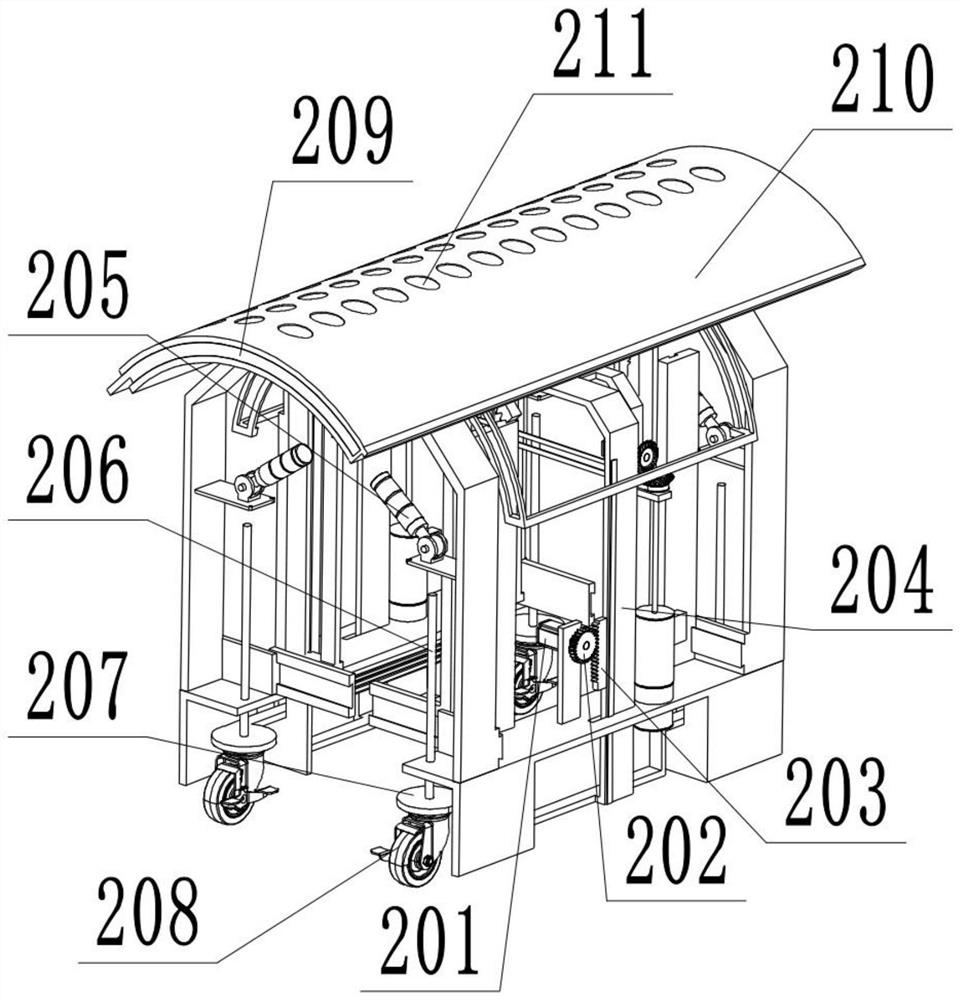

[0032] Example: as Figure 1-Figure 13 The shown anti-collapse tunnel construction disaster prevention and mitigation structure includes a support device 1 and a protection device 2. The protection device is installed on the support device 1, the support device includes a support frame 101, and the protection device 2 includes a support adjustment frame 204. Plate, slide assembly.

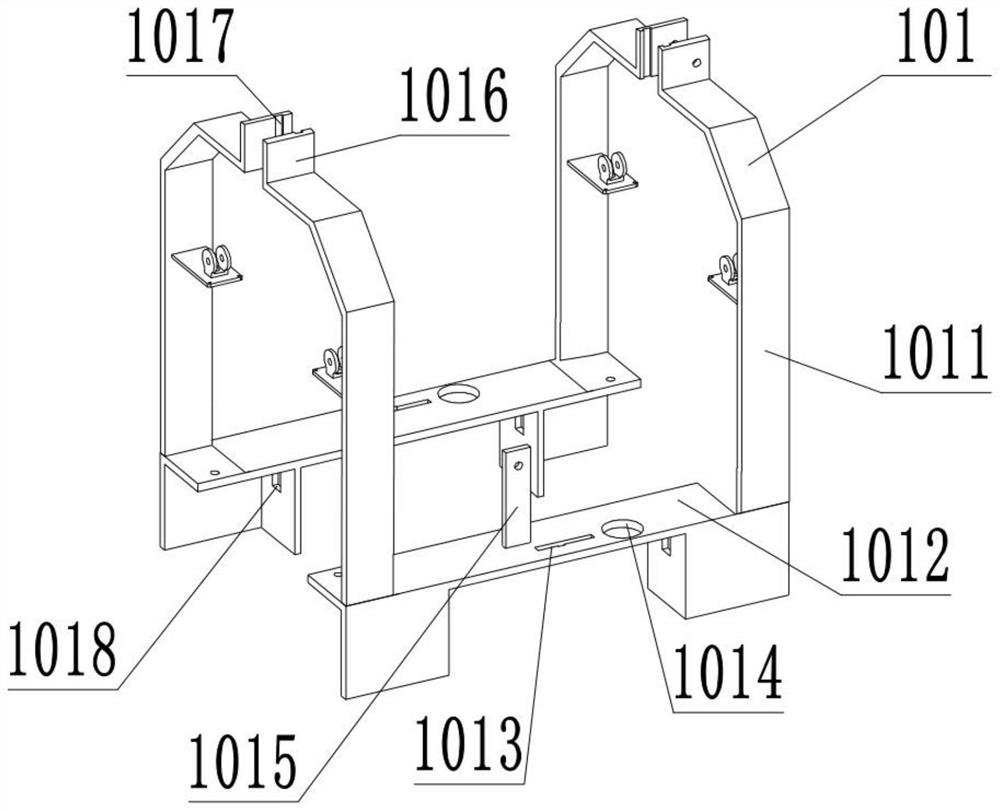

[0033] The support frame 101 is as figure 2As shown, two arched brackets 1011 are included. The two arched brackets are installed on the two bottom brackets 1012 according to the front and rear positions. The middle of each bottom bracket is provided with a long hole 1013 for the support adjustment frame 204 to pass through. An opening 1014 for installing the dust removal fan 217 is provided near the elongated hole, and a vertical plate 1015 for installing the supporting motor 201 is opened next to the elongated hole on a bottom bracket; the top center of the arched bracket is provided with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com