Synchronous construction platform and method for ultrahigh chimney cylinder and lining

A simultaneous construction and platform technology, applied in the direction of formwork/formwork/work frame, tower, building type, etc., can solve the problems of high consumption, low stability of lining construction platform, and difficulty in dismantling and settlement of equipment, achieving The effect of reducing construction consumables, facilitating lining masonry operations, and reducing the difficulty of settlement and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] It should be noted that on the inner wall exceeding the chimney, a ring-shaped cantilever corbel needs to be installed at a height of about ten meters apart, and its function is to expand the force-bearing surface of the cylinder and increase the bearing capacity.

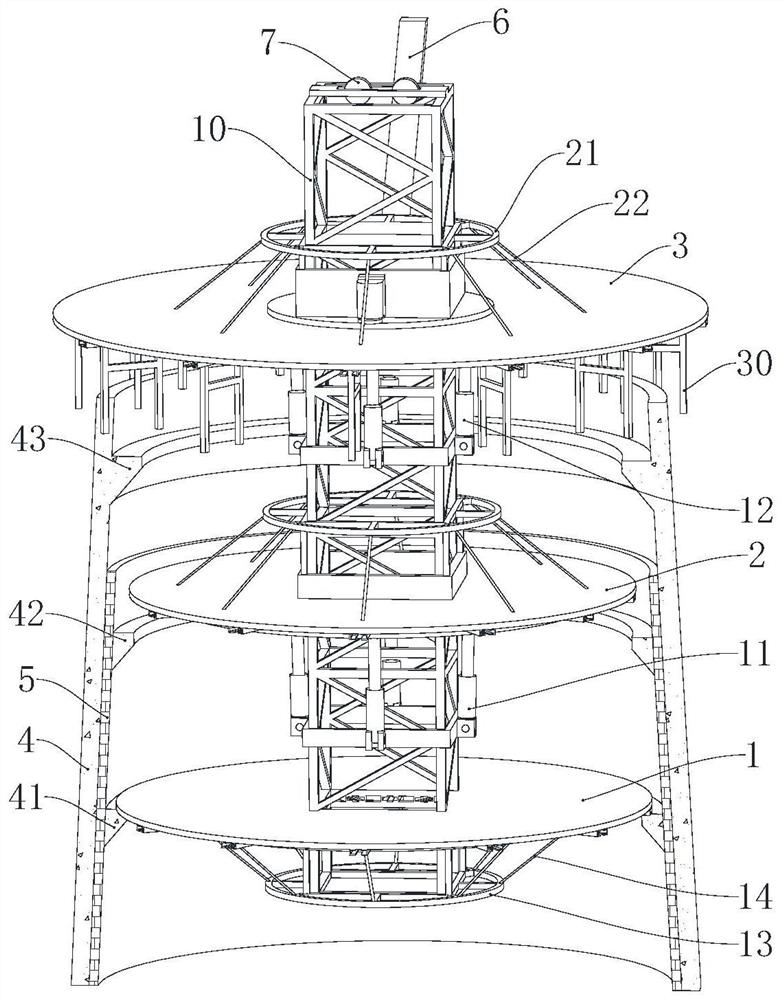

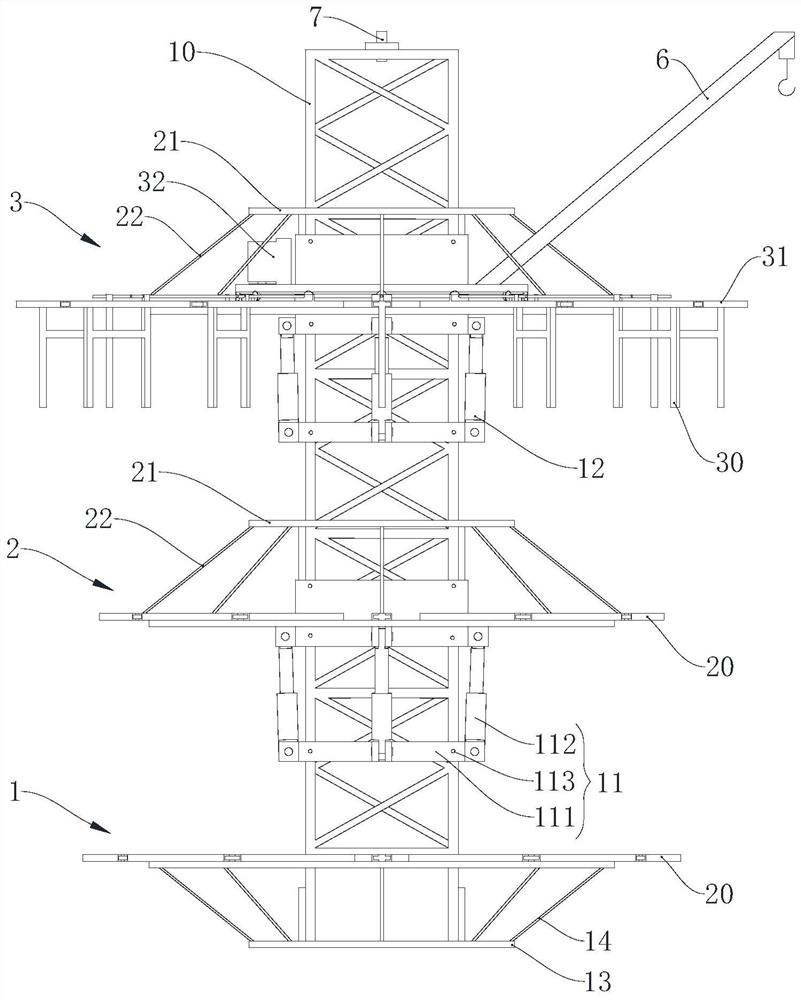

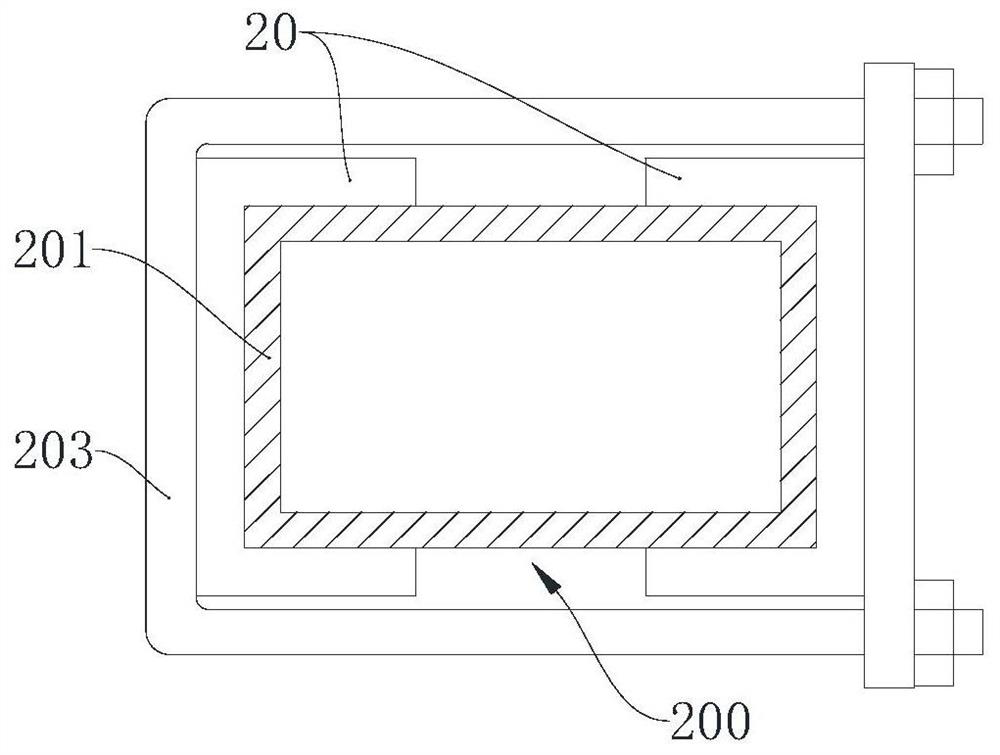

[0034] Please also refer to figure 1 and figure 2 , the synchronous construction platform for the ultra-high chimney body and inner lining provided by the present invention will now be described. The synchronous construction platform of the ultra-high chimney shell and lining includes a chassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com