Steel formwork reinforcing device, arc-shaped combined shaping steel formwork and using method thereof

A formwork reinforcement and shaping steel technology, which is applied to formwork/formwork components, formwork/formwork/work frame connectors, and on-site preparation of building components, etc., can solve the problem that the outer formwork cannot be hoisted and upgraded as a whole, and the efficiency is low. , It is difficult to ensure the flatness of the cast-in-place arc wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

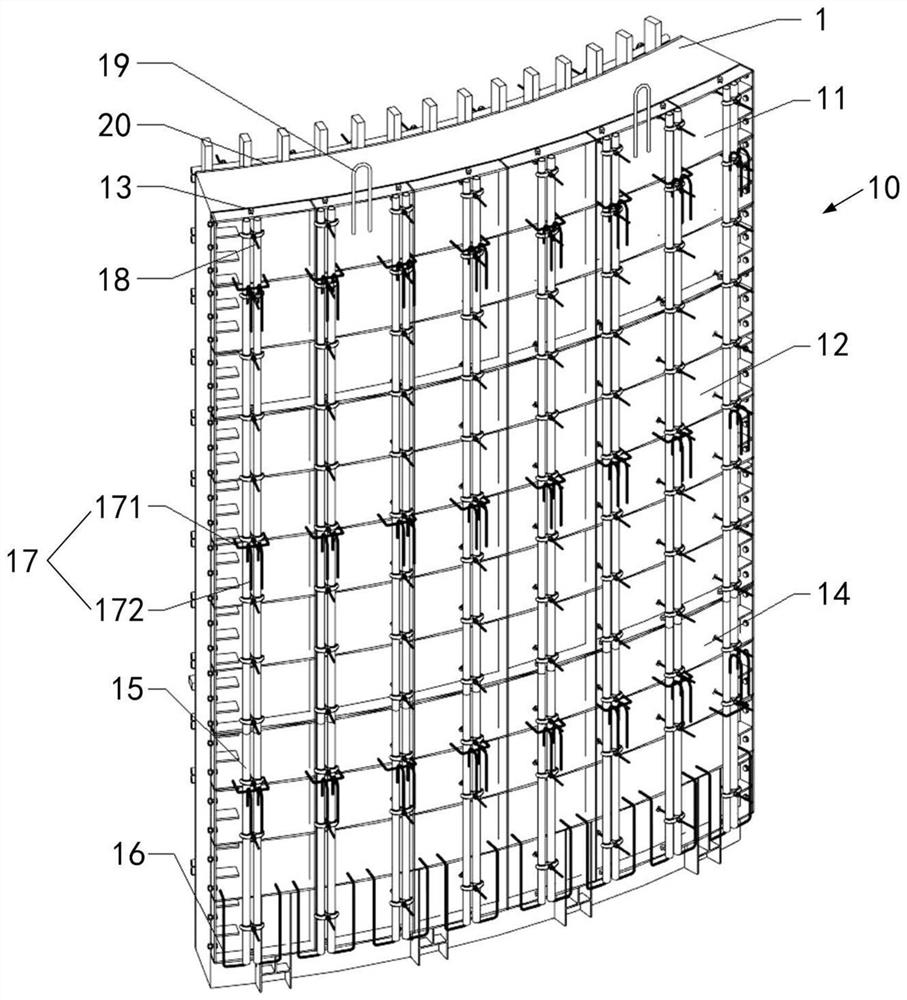

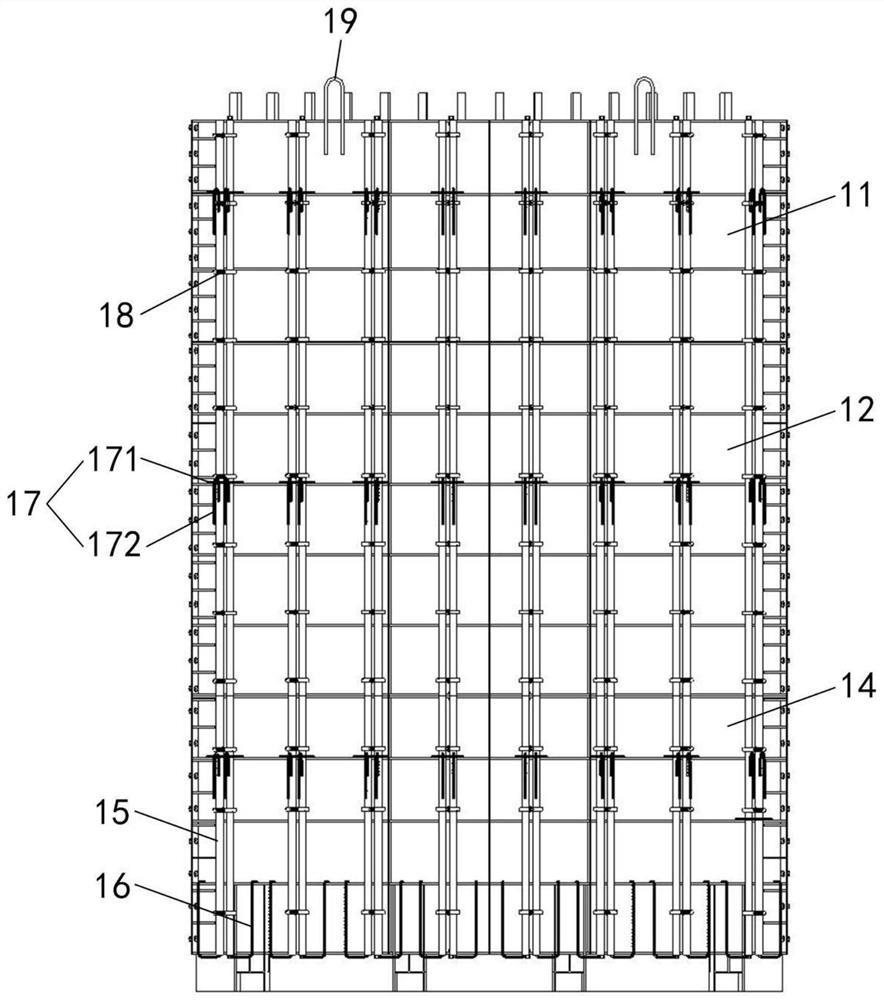

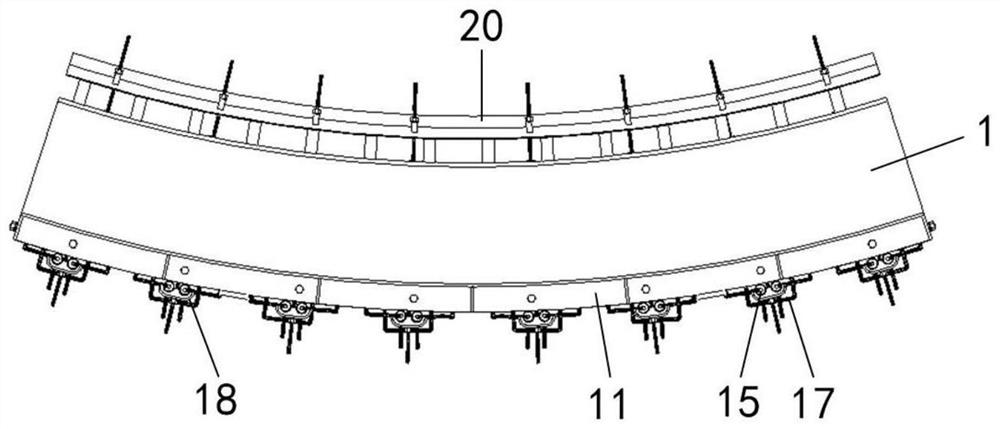

[0033] In this embodiment, the construction of the cast-in-situ arc-shaped reinforced concrete wall 1 is taken as an example. The inner formwork 20 is assembled by wooden formwork, and the outer formwork is an assembled all-steel formwork, and the outer formwork is vertically spliced by three shaped sub-formworks. Formed, respectively, the upper shaping sub-template 11, the middle shaping sub-template 12 and the lower shaping sub-template 14, and the adjacent two shaping sub-templates are threadedly connected by a connecting screw, and the following combination Figure 1 to Figure 11 Describe the formwork reinforcement device of this embodiment, which includes: a pair of parallel and spaced connecting rods 15, a supporting member, three buckle members 17, and a plurality of wall-through screws 18, and the supporting member is fixedly connected to the lower part At the bottom of the shaped sub-formwork 14, a pair of connecting rods 15 are vertically arranged on the outside of ...

Embodiment 2

[0039] combine Figure 1 to Figure 11 Illustrate the arc combined shaped steel formwork 10 of the present embodiment, it comprises at least two shaped sub-formworks, and a plurality of formwork reinforcement devices as described in embodiment 1, the shaped sub-formworks are assembled and screwed together vertically and horizontally, multiple A template reinforcement device is arranged vertically and at intervals along the horizontal extension direction of the assembled shaped sub-formwork, and the supporting parts of the formwork reinforcement device are fixedly connected to the shaped sub-formwork at the bottom, and a pair of connecting rods 15 are vertically arranged on the outside of the shaped sub-formwork. The bottom of the connecting rod 15 is detachably connected to the supporting member, at least two buckle parts 17 are arranged along the length direction of the connecting rod 15, and at least one buckle part 17 is correspondingly arranged on each sub-formwork for shapi...

Embodiment 3

[0043] combine Figure 12 to Figure 16 Illustrate the use method of arc-shaped combined shaped steel formwork 10 of the present invention, concrete steps are as follows:

[0044] Such as Figure 12 As shown, the pre-embedded steel bars of the arc-shaped reinforced concrete shear wall to be poured in the current layer are bound, the arc-shaped inner formwork 20 is set up, and three shaped sub-formworks are hoisted in turn, which are respectively the lower shaped sub-formwork 14, the middle shaped sub-formwork 12 and The upper shaped sub-formwork 11, three shaped sub-formworks are assembled vertically and preliminarily connected into a piece of shaped steel formwork by connecting bolts 13, such as Figure 13 As shown, a plurality of formwork reinforcement devices are arranged vertically and at intervals along the horizontal extension direction of the shaped steel formwork, the support parts of the formwork reinforcement devices are fixed on the outer bottom of the shaped steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com