Light emitting device and manufacturing method thereof

A light-emitting device and quantum dot light-emitting technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of unbalanced electron and hole transport rates, and achieve the promotion of electron and hole transport balance, The effect of slowing down the decline of materials and prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

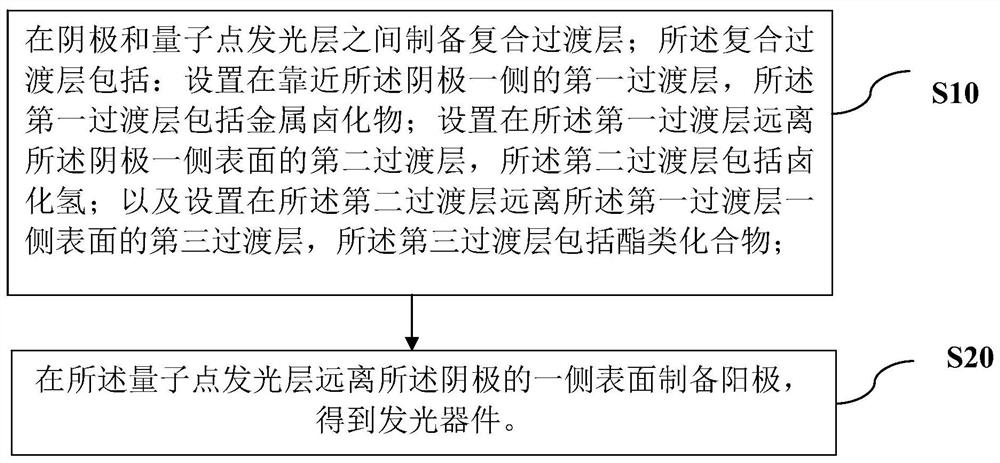

[0021] S20. Prepare an anode on the surface of the quantum dot light-emitting layer away from the cathode to obtain a light-emitting device.

[0026] S12. Prepare a hole functional layer between the quantum dot light-emitting layer and the anode;

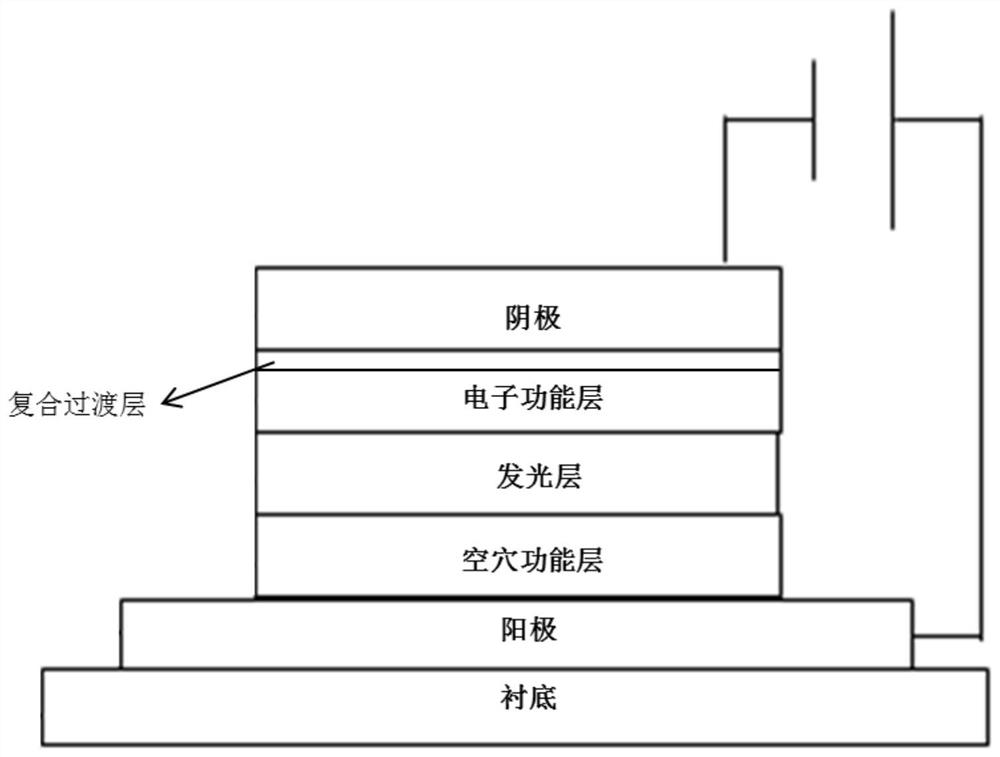

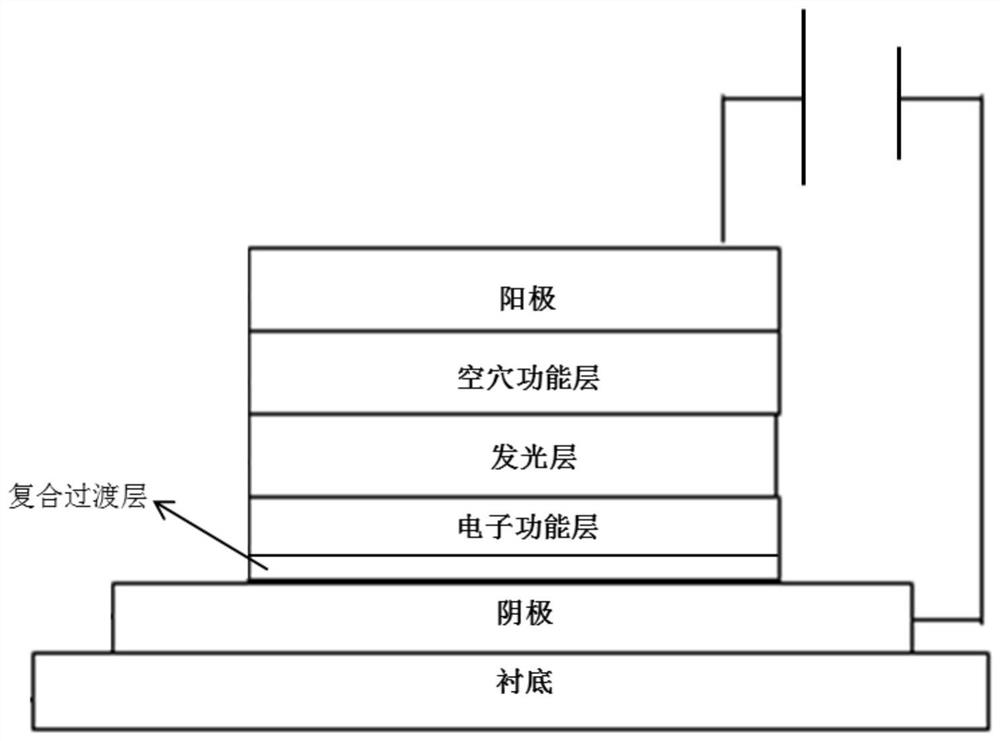

[0028] Specifically, in the above-mentioned step S10, a composite transition layer is set between the cathode and the quantum dot light-emitting layer. the present invention

[0045] In some embodiments, the concentration of the acid halide compound solution is 5-20 mg / mL. If the acid halide compound dissolves

[0046] In some embodiments, the metal element in the metal halide is the same as the metal element in the metal cathode.

[0047] In some embodiments, the thickness of the composite transition layer is 10-20 nanometers. In some specific embodiments, the

[0051] In some embodiments, the thickness of the composite transition layer is 10-20 nanometers. In some specific embodiments, the

[0052] In some embodiments, the cathode ...

Embodiment 1

[0073] Step S14: on the quantum dot light-emitting layer, deposit an ethanol solution of zinc oxide nanomaterials, pre-anneal at 80 ° C for 5 min, remove

[0076] Step S17: annealing at 80° C. for 30 minutes, encapsulating and curing, and completing the preparation of the quantum dot light-emitting device.

Embodiment 2

[0082] Step S24: on the quantum dot light-emitting layer, depositing an ethanol solution of zinc oxide nanomaterials, pre-annealing at 80° C. for 5 min, removing

[0085] Step S27: annealing at 80° C. for 30 minutes, encapsulating and curing, and completing the preparation of the quantum dot light-emitting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com