Hydrogen storage material hydrogen absorption and desorption cycle life testing device and method

A technology for hydrogen storage materials and cycle life, applied in analytical materials, instruments, etc., can solve the problems of data error of hydrogen absorption and desorption capacity, large volume calibration error, slow low-pressure hydrogen outflow rate, etc. The effect of wide range and shortened test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

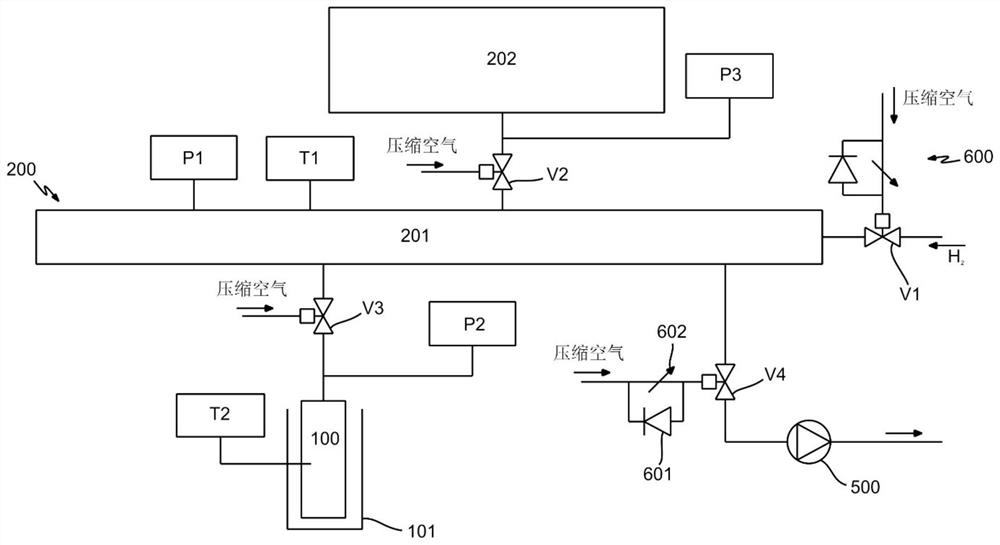

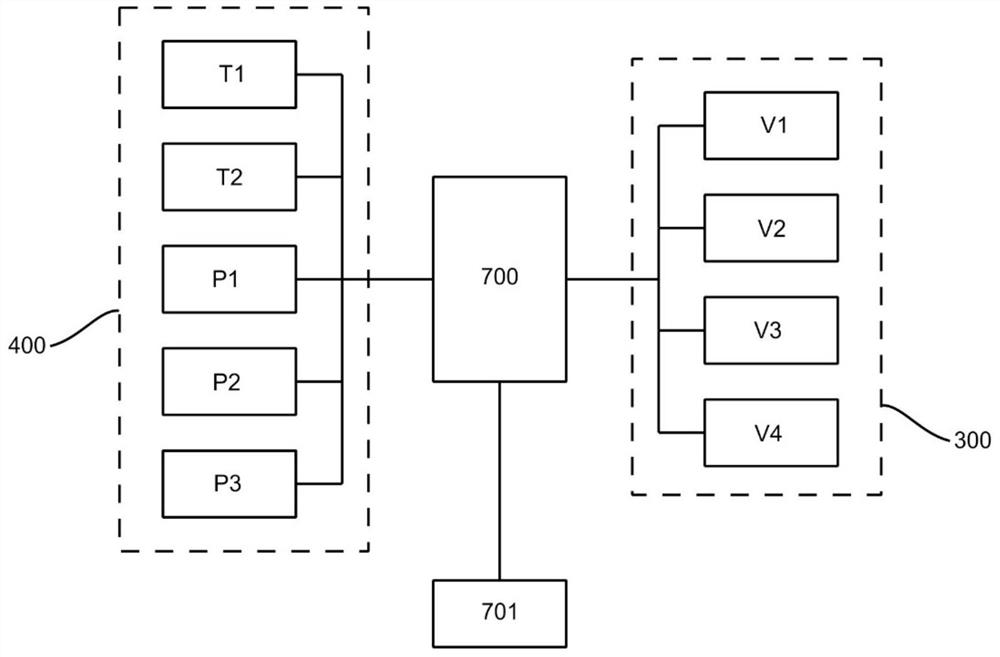

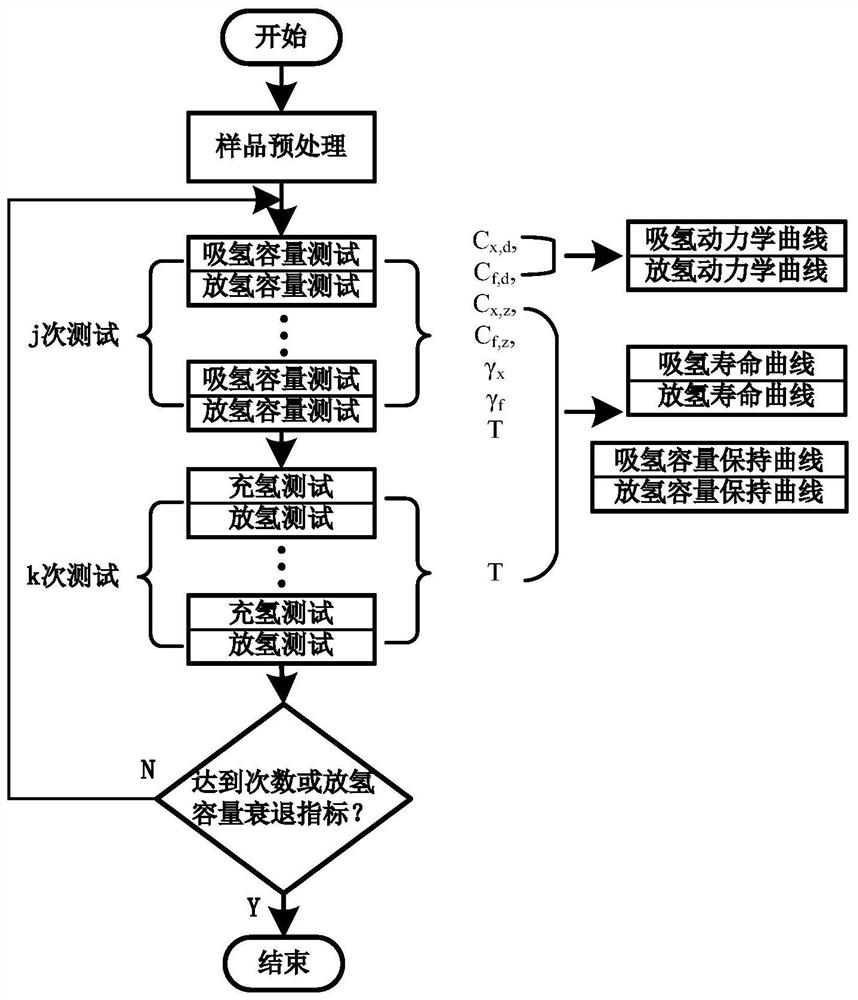

Method used

Image

Examples

Embodiment 1

[0118] Weigh 0.3g of La 0.5 Ce 0.5 Ni 4 The Co standard sample was put into the sample chamber 100, and 0.06 g of quartz wool was placed above it, and then the sample chamber 100 was put into the constant temperature device 101, and the device was evacuated at room temperature. Open the second control valve V2, the third control valve V3, and then gradually open the fourth control valve V4. When the pressure measured by the second pressure sensor P2 is <0.1MPa, start the thermostat 101, set the temperature of the thermostat 101 to 50°C, and the vacuum pump 500 vacuumizes the hydrogen absorption and desorption container 201, the hydrogen desorption container 202 and the sample chamber 100 After 30 minutes, gradually open the first control valve V1, fill in 12MPa hydrogen, turn off the heating function of the thermostat 101, and then lower the sample to room temperature, and then keep the thermostat 101 to keep the temperature at 25°C. The sample pretreatment process ends.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com