Variable-pipe-diameter flowmeter calibration device and calibration method

A technology of runoff and flowmeter, applied in the field of variable pipe diameter flowmeter calibration device, can solve the problems of scientific research work and industrial production, inconsistent real values, related result errors, etc., to reduce the workload of manual measurement and easy operation. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]For the case where the diameter of the gas flow pipeline to be tested does not match the diameter of the flowmeter 2000 tube, simply connect the gas flow pipeline to be tested with the flowmeter 2000 tube to read the readings of the flowmeter 2000, because the gas is a compressible fluid , the gas flow value measured by the flowmeter 2000 at this time is inaccurate, which will lead to errors in the related results of subsequent application of gas flow measurement and calculation, which will affect scientific research work and industrial production. In view of this, this embodiment designs Disclosed is a calibrating device for a variable pipe diameter flowmeter.

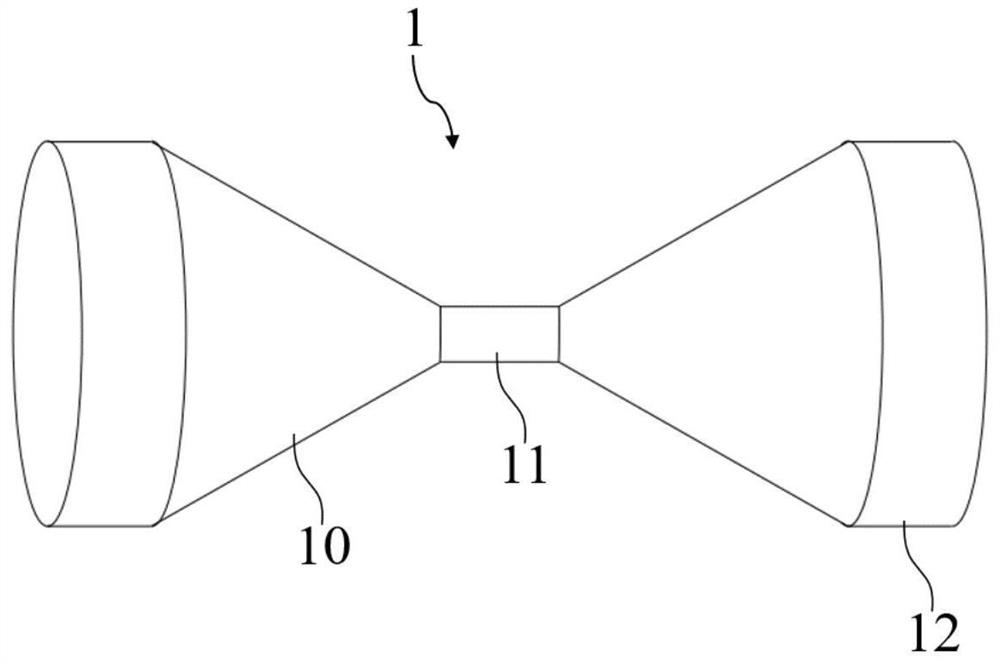

[0057] Such as figure 1 As shown, the flowmeter 2000 is usually connected to the middle of the airflow pipeline to be tested. There are measuring tubes at both ends of the flowmeter 2000, and the airflow pipeline to be tested is divided into the inlet airflow pipeline 1000 to be measured and the outlet airflow p...

Embodiment 2

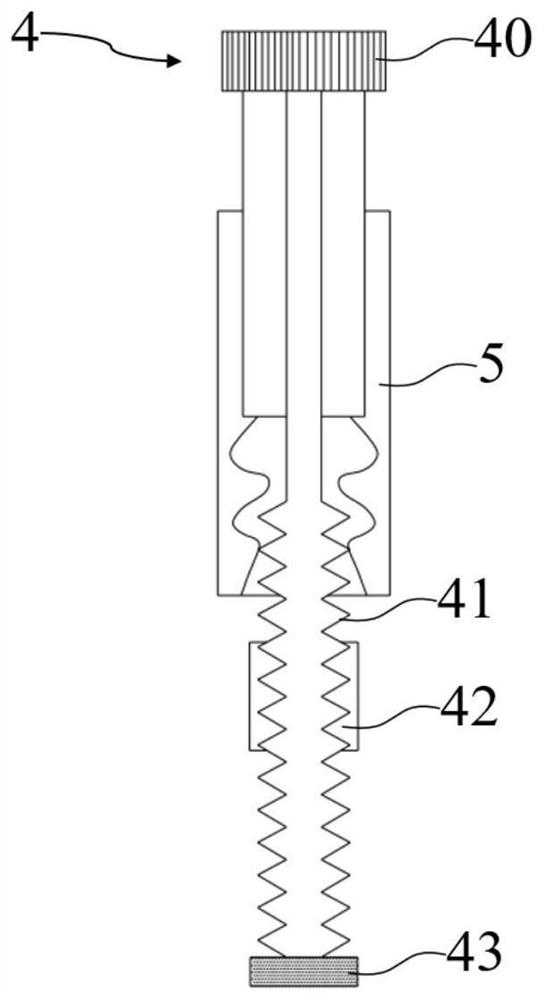

[0066] The variable pipe diameter flowmeter calibration device of this embodiment is further improved on the basis of Embodiment 1, and also includes a radial limiter 4, which passes through the double horn head sleeve 1 and along the double horn head sleeve 1 Set radially, the radial limiter 4 is arranged at both ends of the double horn head sleeve 1, respectively fixing the relative position of the air flow pipe to be measured and the double horn head sleeve 1 and the flowmeter 2000 measuring tube and the double horn head cover The relative position of cylinder 1.

[0067] In order to ensure the fixing of the airflow pipeline to be tested and the double horn head sleeve 1, and the reliable fixing of the flowmeter 2000 measuring tube and the double horn head sleeve 1, this embodiment designs a radial limiter 4 along the radial direction of the airflow pipeline to be tested. And flowmeter 2000 measuring tube for fixed limit.

[0068] Further, this embodiment shows a specific ...

Embodiment 3

[0077] The variable pipe diameter flowmeter calibration device of this embodiment is further improved on the basis of Embodiment 2, and also includes a radial depth sensor 5, which detects the outer pipe diameter of the gas flow pipeline to be measured and the outer pipe of the flowmeter 2000. path.

[0078] In this embodiment, a radial depth sensor 5 is provided to detect the outer diameter of the airflow pipeline to be measured and the outer diameter of the measuring tube of the flowmeter 2000, thereby conveniently measuring and calculating the diameter ratio R of the airflow pipeline to be measured and the measuring tube of the flowmeter 2000, simplifying Data information acquisition process before calibration.

[0079] Further, the radial depth sensor 5 is transmission-connected to the screw rod 41 of the radial limiter 4 , and the outer diameter of the gas flow pipeline to be measured and the outer diameter of the flow meter 2000 measuring tube are measured by detecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com