Gas self-closing valve

A gas self-closing valve and valve body technology, applied in valve details, safety valve, balance valve, etc., can solve the problems of heavy weight and high production cost, and achieve the effect of overall weight reduction, less health hazard, and process environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

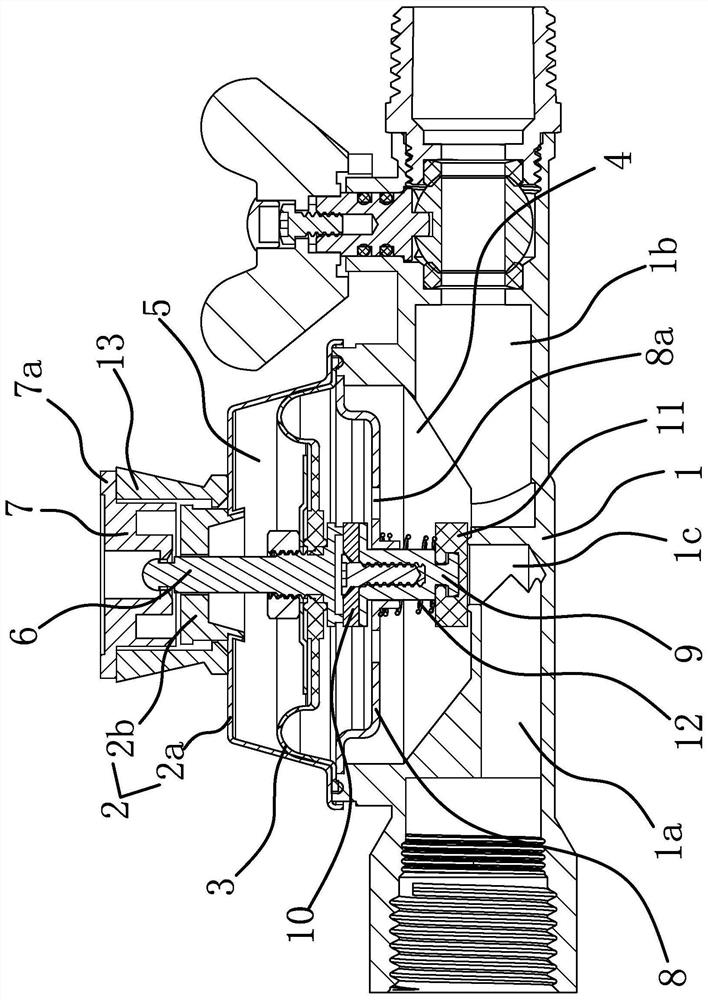

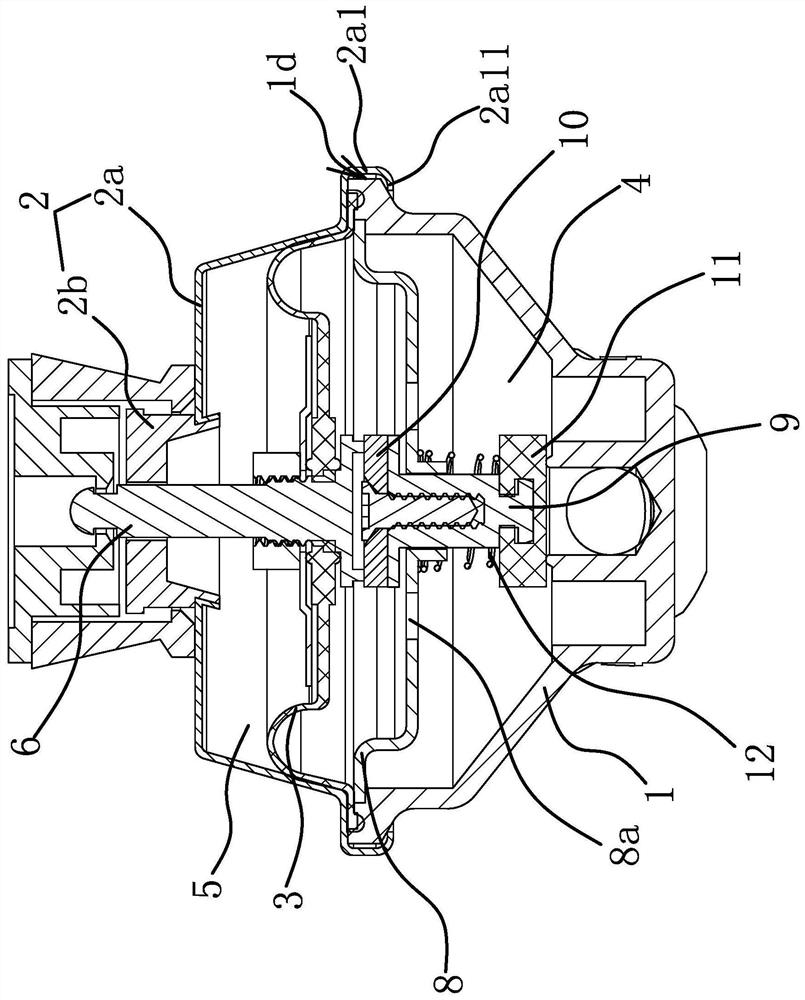

[0027] Such as figure 1 with figure 2 As shown, the gas self-closing valve includes a valve body 1, a valve cover 2 and a diaphragm 3. The upper side of the valve body 1 is open and the valve cover 2 is connected to the upper side of the valve body 1. The outer edge of the diaphragm 3 is clamped on the valve cover. 2 and the valve body 1, a lower chamber 4 is formed between the diaphragm 3 and the inner wall of the valve body 1, and an upper chamber 5 is formed between the diaphragm 3 and the inner wall of the valve cover 2. The left end of the valve body 1 is provided with an air intake channel 1a, and the valve body 1 has an air passage 1c opened in the vertical direction. The right end of the valve body 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com