Plastic cushion featured by coexistence of pipe network and filaments, its production technology and rotary type molding handpiece

A technology of production process and molding head, applied in the field of rotary molding head, can solve the problems of poor overall strength, heavy quality, environmental pollution, etc., and achieve the effects of overall weight reduction, simplified production process, and high bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

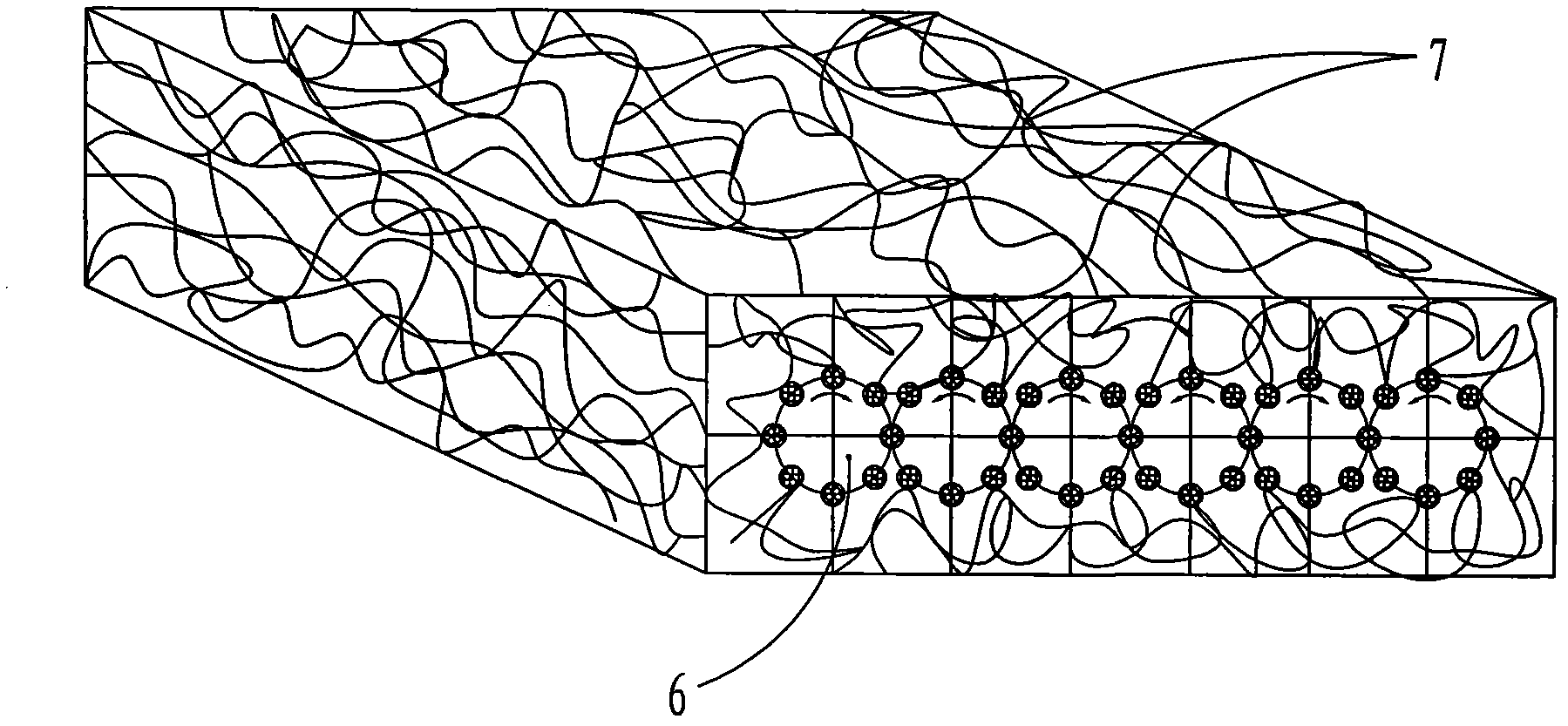

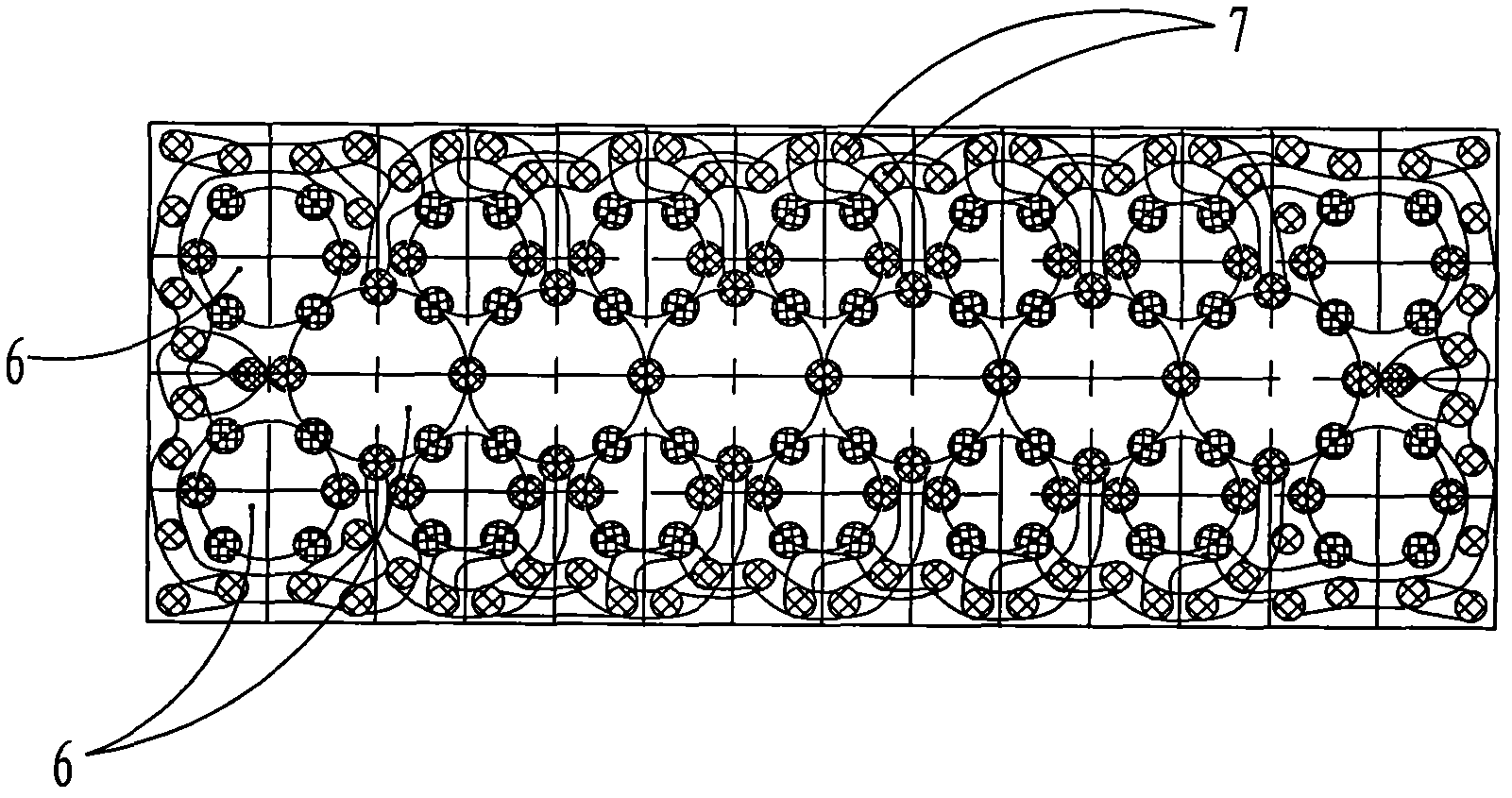

[0029] like figure 1 , 2 Shown: pipe network and random thread coexistence type plastic cushion of the present invention, it comprises disorderly arrangement and the plastic random thread 7 that has connection point between each other, is arranged with pipe network 6 in plastic cushion inner side, and pipe network 6 The shape is cylindrical, that is, the periphery of the pipe network 6 is composed of plastic wires with connection points, a cavity is formed inside the pipe network 6, and the axis of the pipe network 6 is consistent with the longitudinal direction of the plastic cushion. The pipe network 6 forms a skeleton on the inner side of the plastic cushion, which improves the overall strength of the cushion and improves the deformation resistance of the cushion. The inner cavity of the pipe network can also be used to install temperature-regulating components, expanding the application range of the plastic cushion .

[0030] like image 3 , 4 Shown: wherein there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com