Energy-saving environment humidity control and air water production method and system

A technology of environmental humidity and air water production, applied in air conditioning systems, space heating and ventilation, heating methods, etc., can solve problems such as inability to recycle, high energy consumption of dehumidification systems, etc., achieve small footprint and reduce equipment volume , the effect of compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

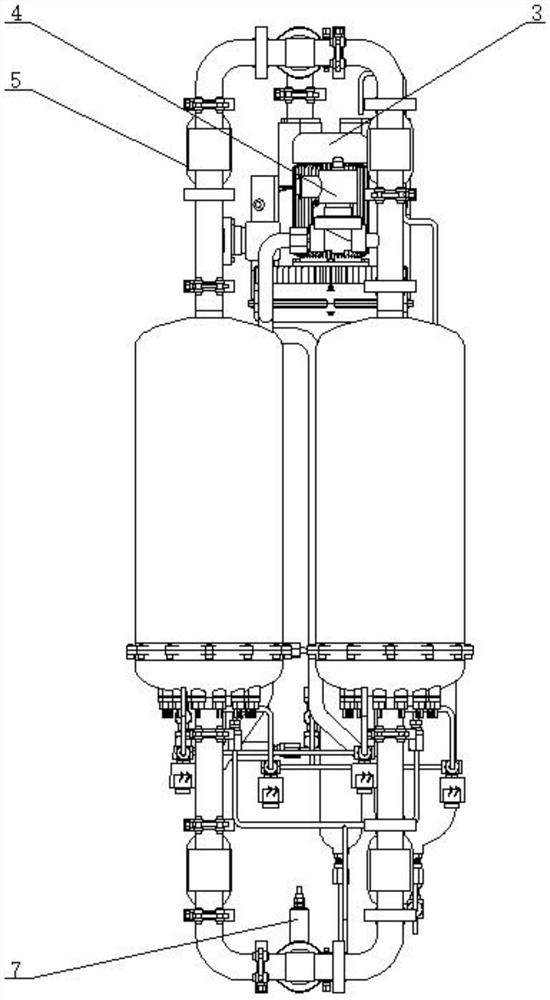

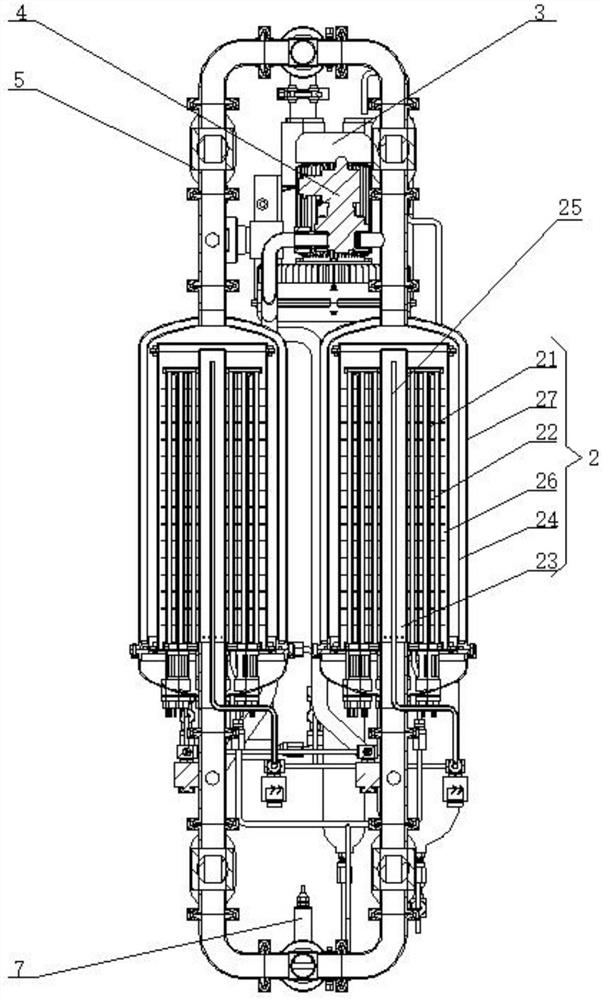

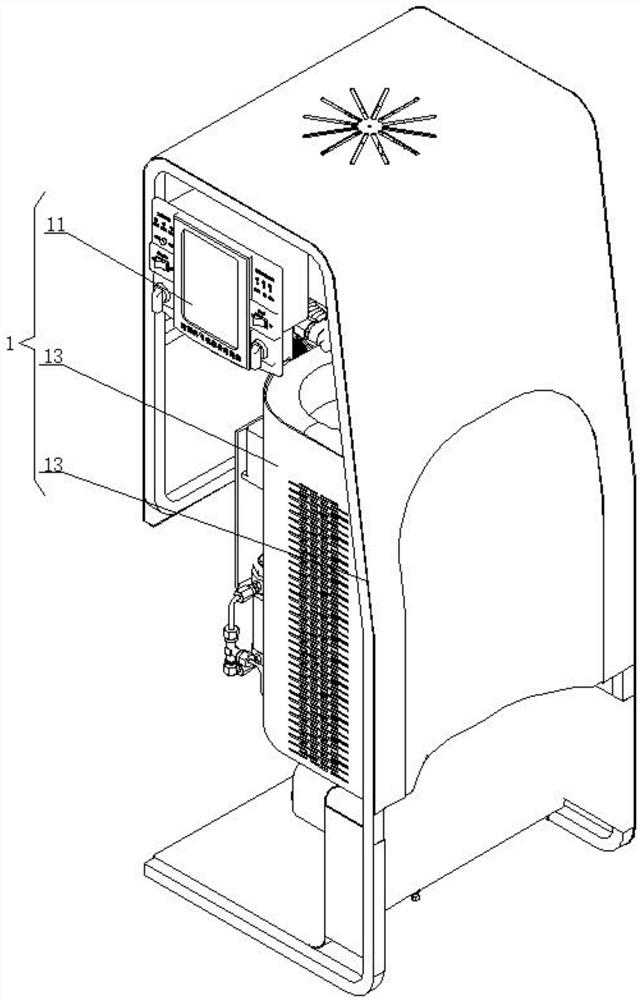

[0063]An energy-saving environmental humidity control and air water production method and system, the environmental humidity control and air water production system includes a set of air circulation control components, a set of water vapor adsorption and desorption and latent heat recovery integrated device 2, a set of catalytic oxidation reaction device 82, a set of air compressor 81, a set of measurement and control system 11, and a set of water quality depth filtration and purification components 85. The measurement and control system 11 is used to monitor the specific desorption time of the water vapor adsorption and desorption and latent heat recovery integrated device 2, and the water vapor adsorption The cavity of the desorption and latent heat recovery integrated device 2 is provided with a heater 21, a tube condenser 22, an inner filter 23, an outer filter 24 and a water-absorbing material 26, and the heater 21 is fixedly installed on one side of the tube condenser 22. ...

Embodiment 2

[0066] Example 2: Please refer to Figure 7 A flow chart of drinking water preparation used in parallel with one set of environmental humidity control and air water production system;

[0067] A set of specific steps for the use of the environmental humidity control and air water production system are:

[0068] Step 1 (1): The air flow enters the water vapor adsorption, desorption and latent heat recovery integrated device 2 through the control valve 83, and the water-absorbing material 26 absorbs the moisture in the air flow; the control valve 83 includes a control valve V1 and a control valve V3, wherein:

[0069] Turn on the intake fan 3, the control valve V1 and the control valve V3, the intake fan 3 drives the air flow through the control valve V1 to enter the water vapor adsorption, desorption and latent heat recovery integrated device 2, the water vapor flow enters the pipeline where the air compressor 81 is located, and the water-absorbing material 26 Absorb the moist...

Embodiment 3

[0074] Example 3: Please refer to Figure 8 Flow chart of drinking water preparation using two sets of water vapor adsorption and desorption and latent heat recovery integrated devices 2 in parallel for medium environment humidity control and air water production system;

[0075] A set of environmental humidity control and air water production system includes a set of air circulation control components, two sets of water vapor adsorption and desorption and latent heat recovery integrated devices 2, two sets of catalytic oxidation reactors 82, a set of air compressors 81, and a set of coolers 84. A set of measurement and control system 11 and a set of water quality depth filtration and purification components 85. The measurement and control system 11 is used to monitor the specific desorption time of the integrated device 2 for water vapor adsorption, desorption and latent heat recovery, and strive for an integrated device for water vapor adsorption, desorption and latent heat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com