Recovery-free inner wall shot blasting machine for nodular cast iron pipe

A ductile iron and shot blasting machine technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve problems such as blockage, reduce shot blasting costs, reduce equipment post-cleaning costs, and avoid assembly errors. , The effect of reducing the cost of shot blasting and improving the coverage of shot blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

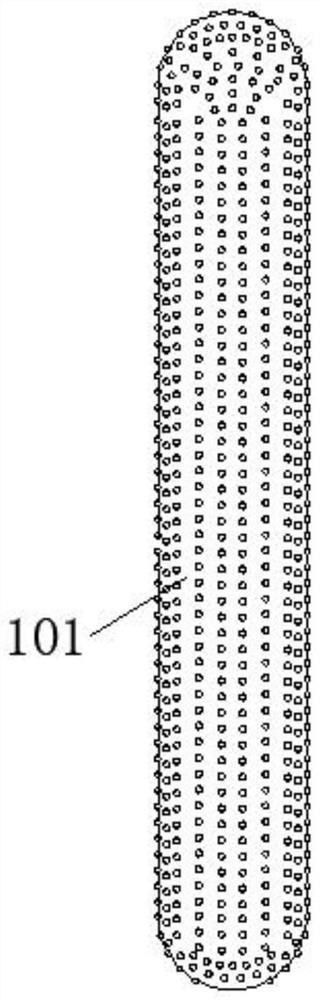

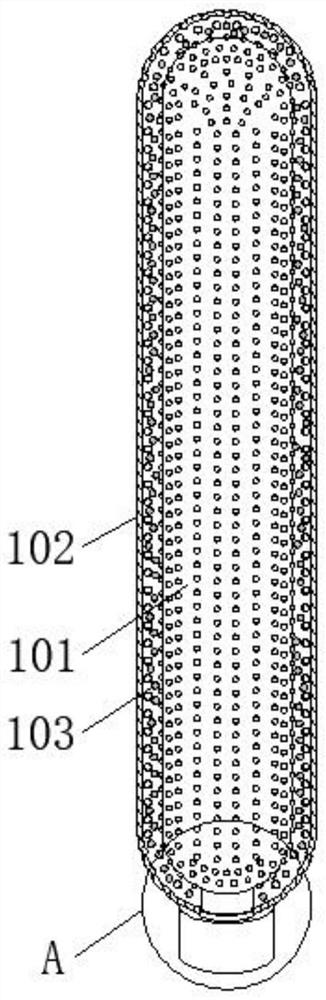

[0049] see Figure 1-6 , a recycling-free inner wall shot blasting machine for ductile iron pipes, comprising a centrifugal shot blasting barrel 1, the centrifugal shot blasting barrel 1 includes an inner barrel 101, a hollow outer barrel 102 and a plurality of projectiles 103, and the plurality of projectiles 103 are all filled in the inner barrel 101 and Between the hollow outer barrels 102, the inner barrel 101 is fixedly connected with a plurality of collision protrusions 1011, and the hollow outer barrel 102 is dug with a plurality of through holes 1021, and the plurality of through holes 1021 are snap-fitted with a resilient film 2 to help The rebound film 2 runs through the hollow outer barrel 102 and extends into it. The ends of the plurality of rebound-assisting films 2 that are close to each other are fixedly connected with snap-in blocks 3 , and the plurality of snap-in blocks 3 are fixedly connected with tension springs. 4. The bottom end of the hollow outer barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com