Online dust removal device for curing oven

A technology of dust removal device and curing furnace, which is used in combination devices, solid separation, chemical instruments and methods, etc., to facilitate cleaning operations, improve stability, and improve air supply efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means and efficacy of the present invention to achieve predetermined amount of invention, the specific embodiments, structures, features, and efficacy of the present invention will be described in detail below with reference to the accommodation invention.

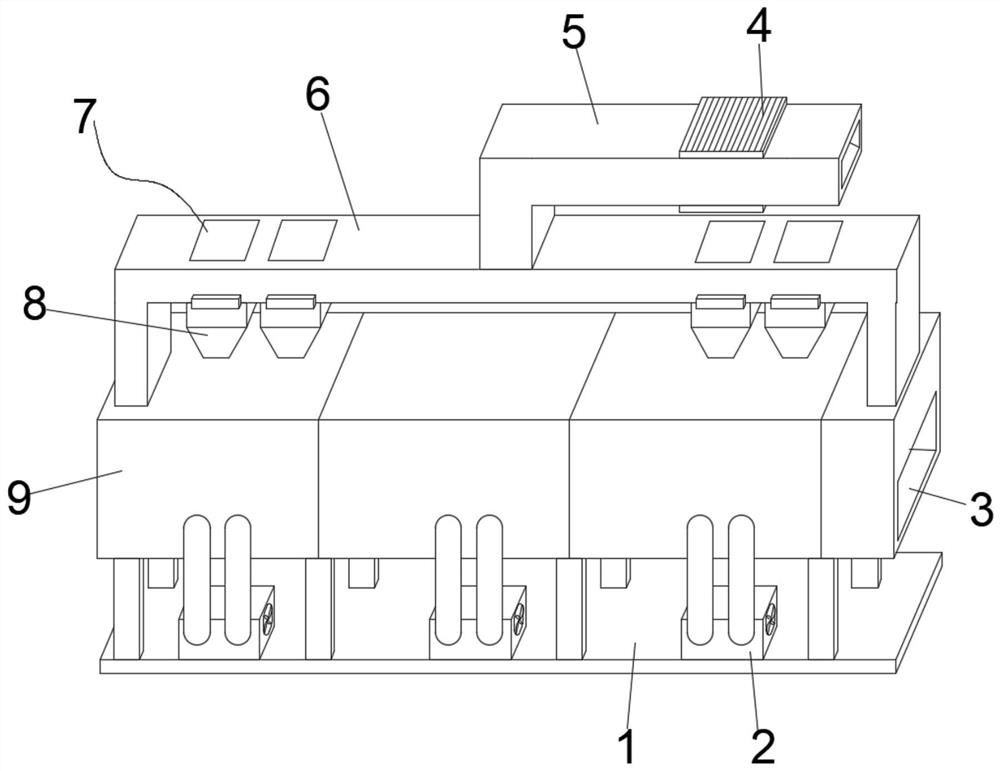

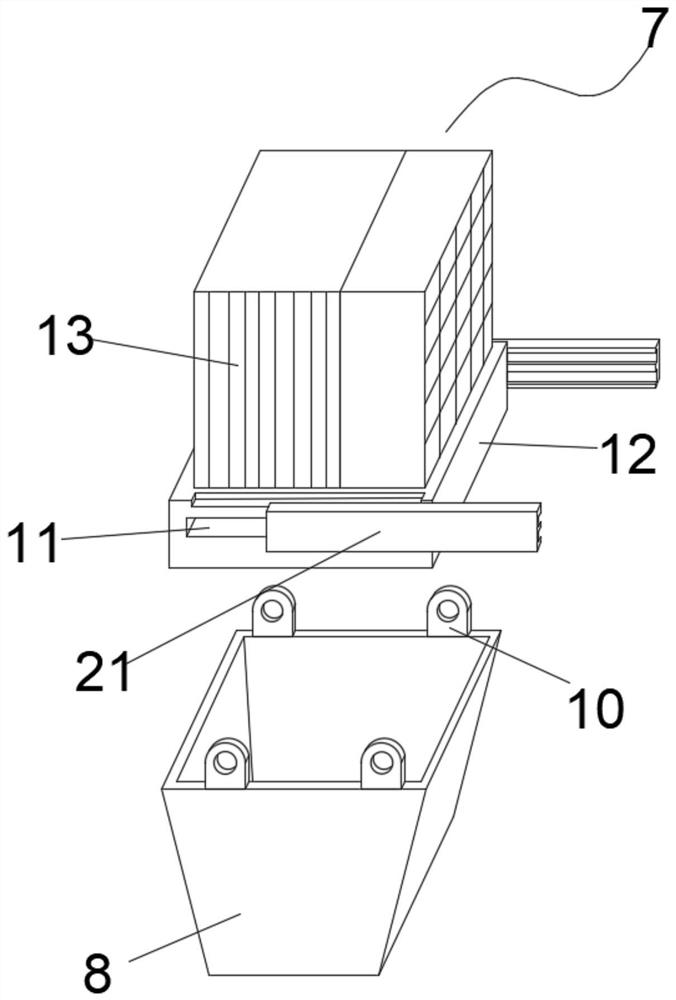

[0029] like Figure 1-4 As shown, a cured furnace is on the line dust removing device, including a communication pipe 6 and a heating tank 9, and the communication pipe 6 is fixedly mounted on the upper outer surface of the heating tank 9, and a plurality of stops of the heating tank 9 are provided with a number of cranes 2, and the communication pipe 6 Both ends are provided with two sets of electrostatic precipitator 7 for dust removal operation when the dust generated when the glass cured heating is heated, and the connecting tube 6 and the electrostatic dust collector 7 are fixed, and the communication tube 6 is spliced. The upper end position is fixedly mounted, the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com