Manufacturing method of PVDF micro-force sensor and application method of PVDF micro-force sensor in surgical instrument

A micro-force sensor and surgical instrument technology, applied in the field of sensors, can solve the problems of rotational atherectomy head incarceration, no-reflow, coronary perforation or cardiac tamponade, etc., to achieve high sensitivity, reduce stimulation, and reduce the risk of complications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

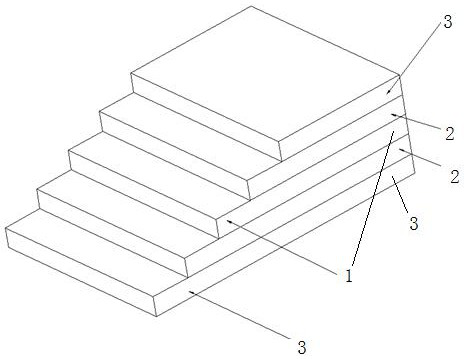

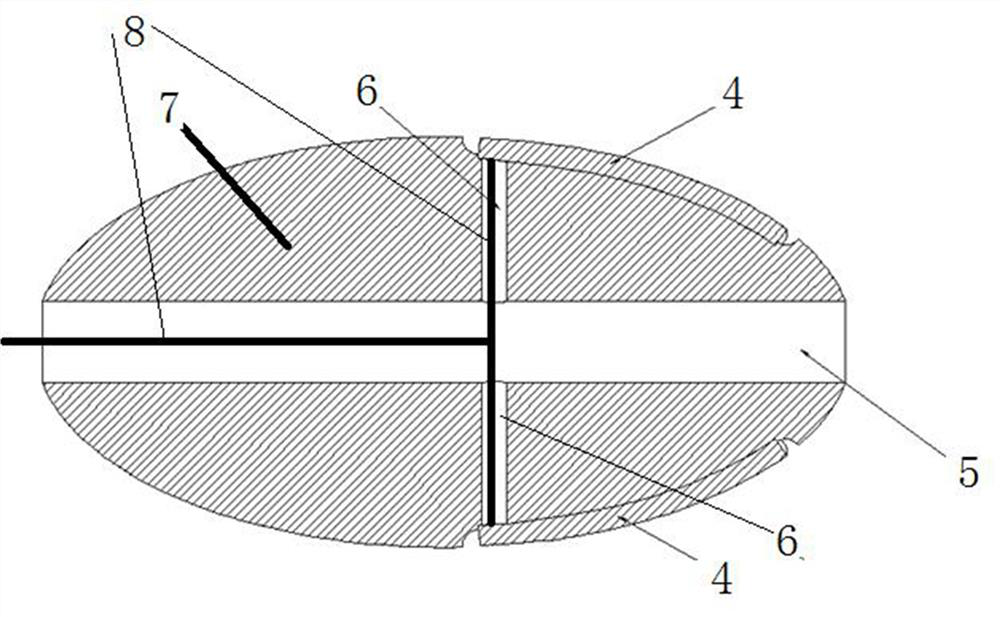

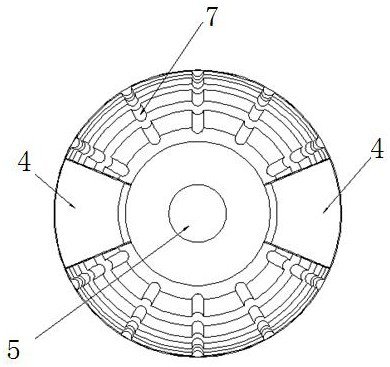

[0031] As shown in the figure, the manufacturing method of the PVDF micro-force sensor is used to prepare a sensor capable of detecting the force data of the cardiovascular interventional surgical instrument in the blood vessel, and the micro-force sensor 4 is an elastic interlayer encapsulated with a waterproof and insulating protective film 3 Structure, including the piezoelectric film 1 as the middle layer of the elastic sandwich structure, and also includes two electrodes 2 connected to the top surface and the bottom surface of the piezoelectric film respectively; the elastic sandwich structure is embedded in the installation groove of the surgical instrument and its bottom surface Or the top surface is located at the outer surface of the surgical instrument. When the force of the surgical instrument in the blood vessel is transmitted to the micro force sensor, the piezoelectric film of the micro force sensor generates a detection electrical signal.

[0032] The piezoelectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com