Electrolyte infiltration method of lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the direction of secondary battery charging/discharging, secondary battery, electrolyte battery manufacturing, etc., can solve the problem that the infiltration effect is difficult to further improve, so as to avoid the occurrence of lithium precipitation, improve the effect, molecular The effect of enhanced diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

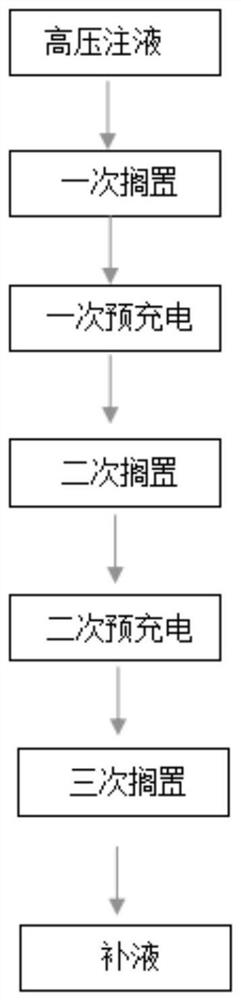

[0055] This embodiment provides an electrolyte infiltration method for a lithium-ion battery, and the specific operation includes the following steps:

[0056] High-pressure liquid injection, using 10 cycles to inject the electrolyte into the 2MEB (44.3*220*122) square battery, the battery capacity is 180Ah, the battery is mainly composed of battery structural parts, diaphragm, electrolyte, positive electrode and negative electrode . Among them, the structural parts are welded by the aluminum cover plate and the aluminum shell to form the external structure. The inside of the shell is mainly the positive plate, the negative plate and the diaphragm through Z-shaped laminations, which are stacked layer by layer. The electrolyte is injected through the reserved liquid of the cover plate. Pores are injected into the inside of the case to infiltrate the positive and negative plates and separators. The electrolyte solution is DMC:EC:DEC:EMC=1:1:1:1, where the liquid injection volum...

Embodiment 2

[0086] This embodiment provides an electrolyte infiltration method for a lithium-ion battery, and the specific operation includes the following steps:

[0087] High-pressure liquid injection, using 10 cycles to inject the electrolyte into the 2MEB (44.3*220*122) square battery, the battery capacity is 180Ah, the battery is mainly composed of battery structural parts, diaphragm, electrolyte, positive electrode and negative electrode . Among them, the structural parts are welded by the aluminum cover plate and the aluminum shell to form the external structure. The inside of the shell is mainly the positive plate, the negative plate and the diaphragm through Z-shaped laminations, which are stacked layer by layer. The electrolyte is injected through the reserved liquid of the cover plate. Pores are injected into the inside of the case to infiltrate the positive and negative plates and separators. The electrolyte solution is DMC:EC:DEC:EMC=1:1:1:1, where the liquid injection volum...

Embodiment 3

[0117] This embodiment provides an electrolyte infiltration method for a lithium-ion battery, and the specific operation includes the following steps:

[0118] High-pressure liquid injection, using 10 cycles to inject the electrolyte into the 2MEB (44.3*220*122) square battery, the battery capacity is 180Ah, the battery is mainly composed of battery structural parts, diaphragm, electrolyte, positive electrode and negative electrode . Among them, the structural parts are welded by the aluminum cover plate and the aluminum shell to form the external structure. The inside of the shell is mainly the positive plate, the negative plate and the diaphragm through Z-shaped laminations, which are stacked layer by layer. The electrolyte is injected through the reserved liquid of the cover plate. Pores are injected into the inside of the case to infiltrate the positive and negative plates and separators. The electrolyte solution is DMC:EC:DEC:EMC=1:1:1:1, where the liquid injection volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com