Grease distributor, grease lubricating system and lubricating grease changing system

A grease distributor and distributor technology, used in distribution devices, lubricating parts, engine lubrication, etc., can solve the problems of low oil replenishment accuracy and poor lubrication effect of lubricating parts, and achieve compact layout, easy processing, and simplified system. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

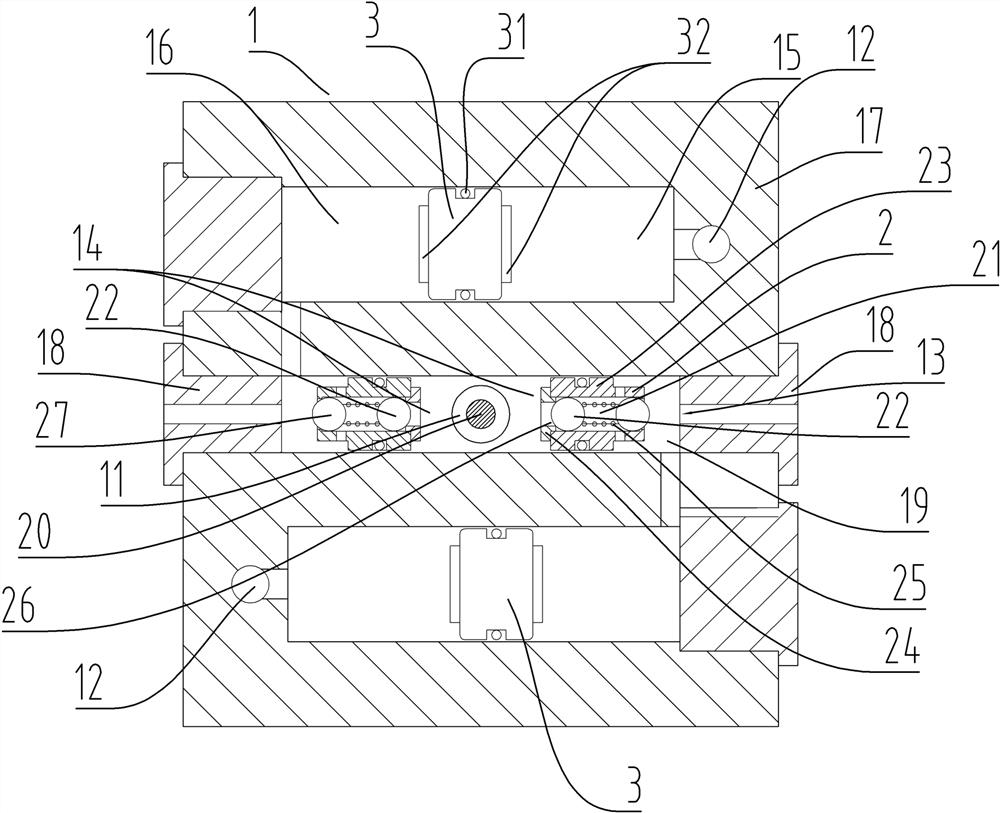

[0156] Specific embodiment 1 of the grease dispenser of the present invention: as figure 1 As shown, the grease distributor includes a distributor housing 1 and an oil distribution unit arranged on the distributor housing 1. In this embodiment, there are four oil distribution units. figure 1 Only two oil distribution units are shown in .

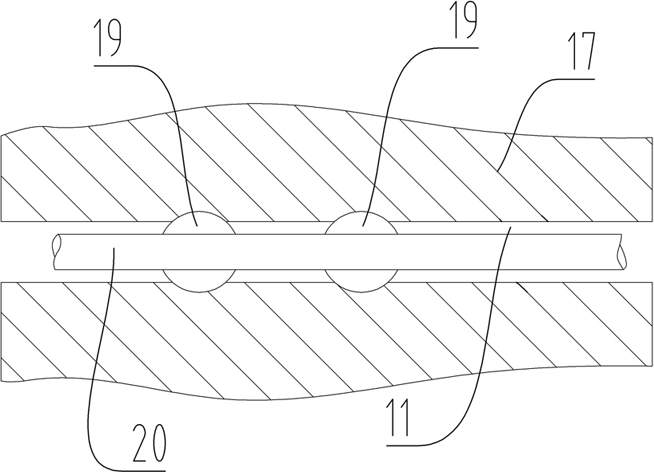

[0157] The distributor housing 1 has an oil supply channel 11 and an oil pressure channel 12. The oil supply channel 11 is used to supply grease to each oil distribution unit, and the oil pressure channel is used to supply fluid medium to each oil distribution unit. Each oil distribution unit shares the oil supply channel 11 , and each oil distribution unit shares the oil pressure channel 12 . The oil distribution unit includes an oil outlet 13, an oil supply chamber 14 communicated with the oil supply passage 11, and a power chamber 15 communicated with the pressure oil passage 12, and the oil outlet 13 is used for oil discharge. The oil ...

specific Embodiment 2

[0177] The specific embodiment 2 of the grease distributor of the present invention, the difference of the grease distributor in the above-mentioned specific embodiment 1 of the grease distributor in this embodiment is only: as image 3 As shown, the one-way valve core 222 in this embodiment is arranged on the housing 217, and an oil injection channel is additionally provided between the oil storage chamber 216 and the oil supply chamber 214, and the one-way valve core 222 is arranged in the oil injection channel. The function of the oil supply valve core 202 in the embodiment is to control the opening and closing of the oil outlet 213 . In order to ensure that the oil supply spool 202 is stably in the oil storage state, a spool rod is provided on the side of the oil supply spool 202 close to the oil storage chamber 216, and the spool rod extends into the housing 217 and fits in a sliding seal with the housing 217, The pressure receiving area of the oil supply valve core 202...

specific Embodiment 3

[0179] The specific embodiment 3 of the grease distributor of the present invention, the difference of the grease distributor in the above-mentioned specific embodiment 1 of the grease distributor in this embodiment is only: as Figure 4 As shown, in this embodiment, the oil supply valve core is an elastic valve core integrally formed, and an elastic cup 3021 is arranged on the outer periphery of the elastic valve core, and the mouth of the elastic cup 3021 is set facing away from the oil supply chamber 314. 3021 constitutes the one-way oil passing structure. In this embodiment, the oil outlet 313 is arranged on the cover 318 of the oil supply valve core, and one end surface of the oil supply valve core 302 in the moving direction forms a sealing surface of the oil outlet 313 for sealing the oil outlet 313 . The moving direction of the oil pressure piston 3 in this embodiment is consistent with the moving direction of the oil supply valve core 302 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com