Modularized room convenient to assemble

An easy-to-assemble and modular technology, applied in construction, building construction, etc., can solve the problems of general stability and practicability, troublesome roof structure installation and connection, etc., achieve good stability, reduce transportation costs, and facilitate disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

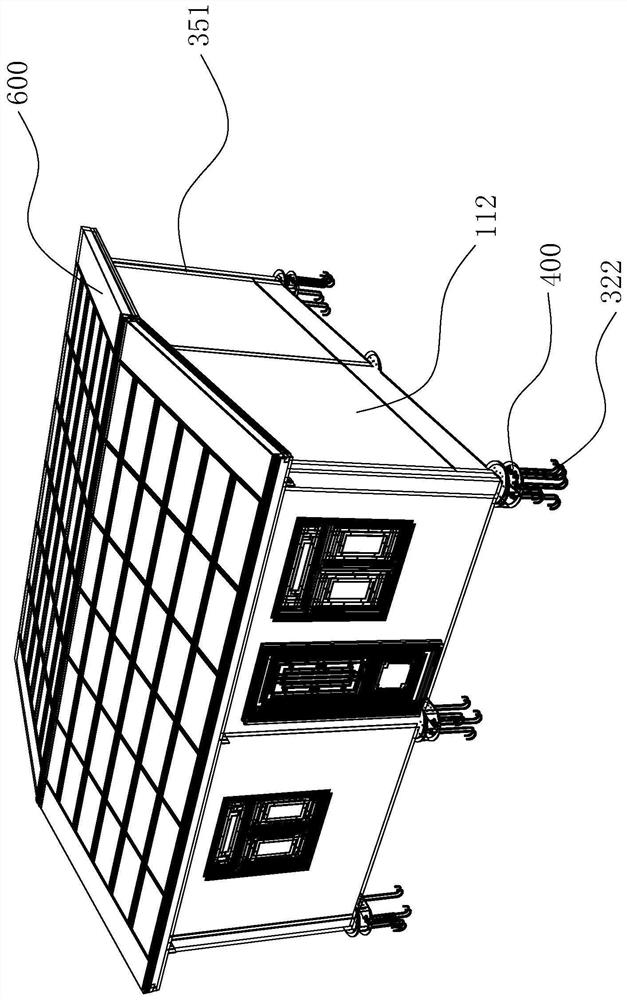

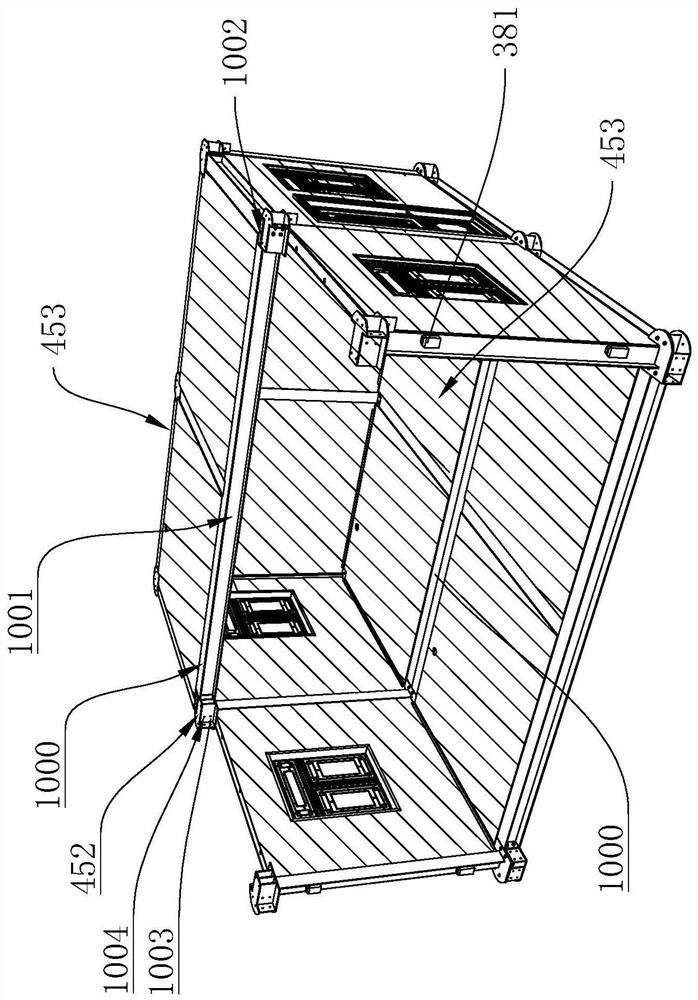

[0040] like Figure 1-7 As shown, a modular room that is easy to assemble includes a horizontal beam 1000, two support bases 452 are connected to the horizontal beam 1000 and the support base 452 is connected to the end of the horizontal beam 1000, and the horizontal beam 1000 Floor installation grooves 1001 are provided on both sides, and modular floor assemblies 453 are also included. The modular floor assemblies 453 are inserted into the floor installation grooves 1001, and a corner column 351 is provided at both ends of the horizontal beam 1000. The corner column 351 is located between the two supporting seats 452, the modular wall 112 is connected to the corner column 351, the modular wall 112 is matched with the modular floor assembly 453, and the above modular floor assembly 453 A roof portion 600 is provided, and the top of the corner column 351 and the top of the modular wall 112 are respectively connected to the roof portion 600 .

[0041]In the present invention, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com