Detachable soil body vibration reduction structure constructed based on vibration reduction and wave absorption material

A technology of wave-absorbing materials and vibration-damping structures, which can be used in infrastructure engineering, buildings, protective devices, etc., and can solve problems such as poor shock-absorbing effect and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

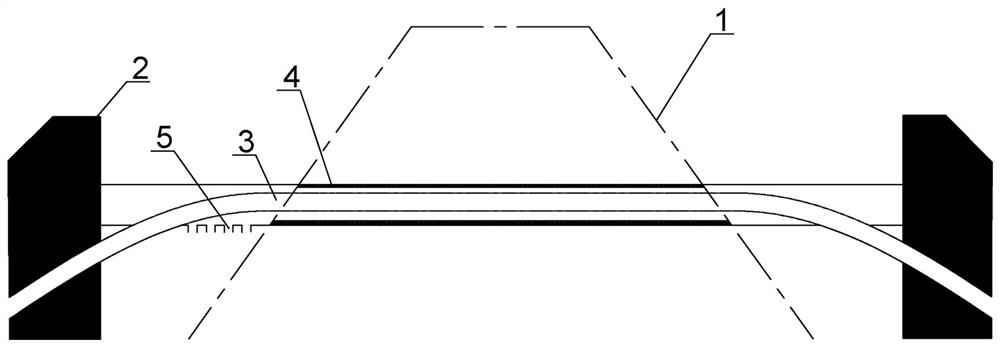

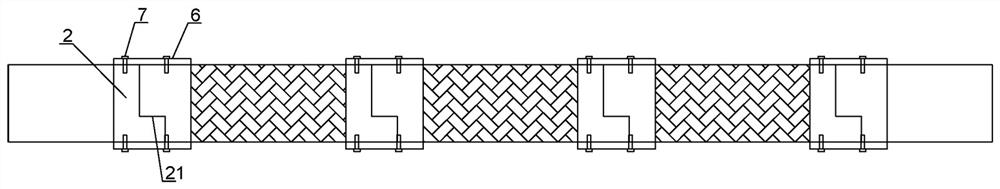

Embodiment 1

[0030]Embodiment 1: This embodiment aims to provide a detachable soil vibration-damping structure based on vibration-absorbing materials, which is mainly used for penetrating soil engineering. Internal vibration sources and external vibration sources (such as earthquakes) ) caused by the impact on engineering stability, in order to ensure the basic stability of soil engineering under the action of internal (common in water pipelines) or external vibration sources (common in earthquakes). Currently, steel pipes are usually placed in reinforced concrete box culverts in the embankment pipeline structure used in current projects, and the gap between the steel pipes and box culverts is filled with medium-coarse sand. Since the structure is relatively simple, and because the density of the filling material is not high and there is a certain gap between the structures, in the case of normal operation of the high-pressure water pipeline, the phenomenon of vibration of the surrounding s...

Embodiment 2

[0038] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further explains the structure of the wave-absorbing concrete material layer.

[0039] In this embodiment, two layers of wave-absorbing concrete material layers are arranged at intervals, and a wave-absorbing cavity 49 is formed between the two layers, wherein the drainage cavity between the inner layer of wave-absorbing concrete material layer and the buffer layer, and the outer layer of wave-absorbing concrete material layer and the transition layer connections.

[0040] In this embodiment, a detachable damping layer is provided, and its inner layer is a wave-absorbing cavity 49 with a certain thickness. The specific thickness of the wave-absorbing cavity 49 is determined by the period length of the vibration wave generated by the vibration source. Generally, it is a period length, which is used to refract and reflect the vibration wave, and to reduce the magnit...

Embodiment 3

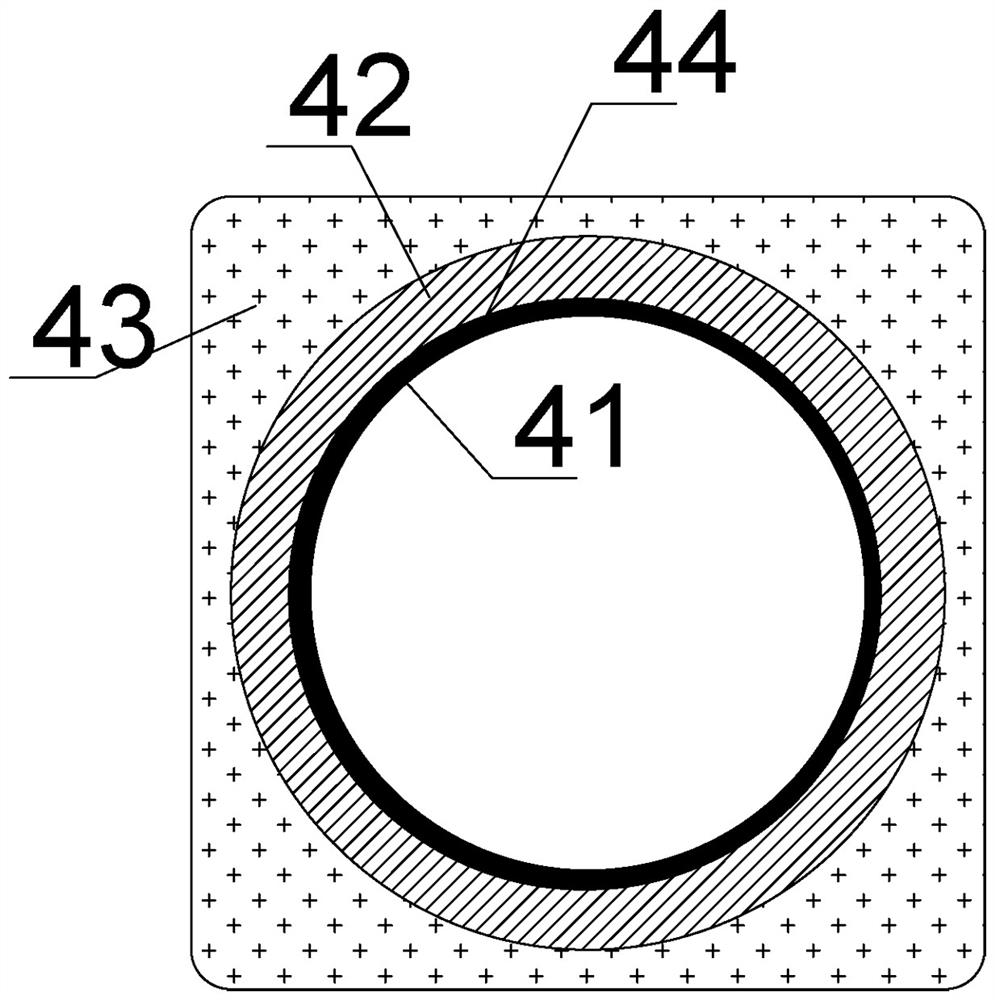

[0041] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further explains the structure of the buffer layer and the steel fiber concrete layer.

[0042] The thickness of the buffer layer 43 is twice the thickness of the steel fiber concrete layer 42. At the same time, the thickness of the buffer layer outside the steel fiber concrete material layer 42 is related to the diameter of the pipe body, the diameter of the pipe body a and the thickness of the steel fiber concrete. If the steel fiber concrete material layer used is b, and b is not greater than 2 cm, it means that the vibration level is small, and the thickness of the buffer layer used at this time is generally 5 cm. If the vibration level is relatively large and the thickness of the steel fiber concrete used is greater than 4 cm, the thickness of the external buffer layer is generally twice the thickness of the steel fiber concrete layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com