Overlap welding tool for coordinating rod of millimeter wave filter

A filter and millimeter wave technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as low welding precision, poor welding consistency and reliability, and achieve high production efficiency, strong solder joint reliability, and The effect of accurate welding arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

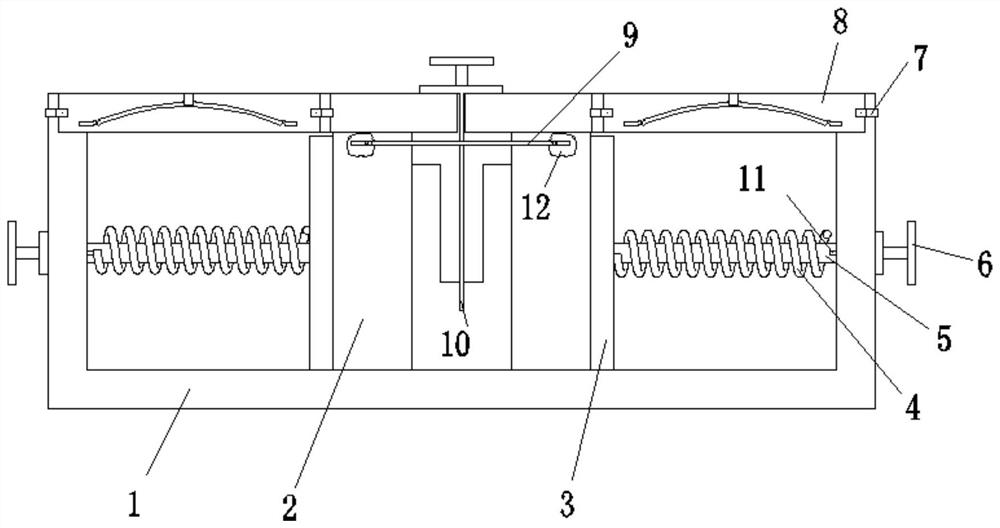

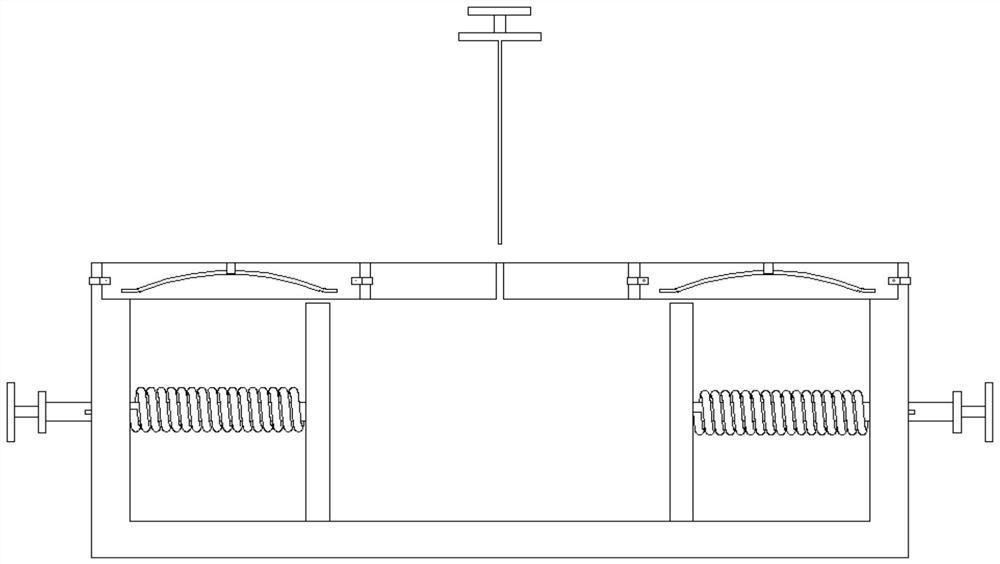

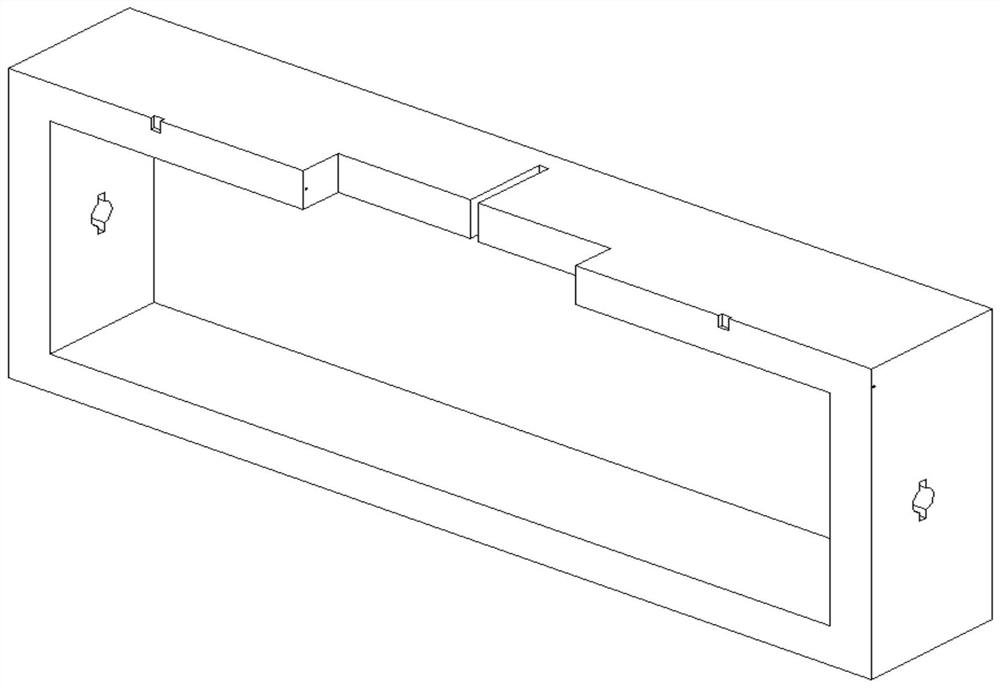

[0028] Such as Figure 1-8 As shown, this embodiment provides a technical solution: a lap welding tool for a millimeter-wave filter coordination rod, including a positioning housing 1, a baffle plate 3, a spring 4, a push-pull rod 5, a feeler gauge 10, and an orthopedic plate 8. The positioning housing 1 is a cuboid structure with a cavity inside or a cube structure with a cavity inside;

[0029] The baffle 3 is symmetrically arranged inside the positioning housing 1, and the opposite sides of the baffle 3 are respectively connected to one end of the push-pull rod 5, and the other end of the push-pull rod 5 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com