Paint spraying device for automobile assembly line

An assembly line and automobile technology, applied in the direction of spraying devices, spray booths, laser welding equipment, etc., can solve the problems of heavy pigment odor, heavy pollution of the working environment, and more manual participation, etc., to achieve stable spray paint color, good spray paint effect, and uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

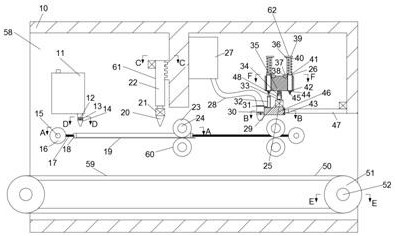

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

[0024] refer to Figure 1-8 According to an embodiment of the present invention, a paint spraying device for an automobile assembly line includes a casing 10, which is provided with a functional cavity 58 communicating with the outside world, and is provided with a stabilizing mechanism 60, a laser Mechanism 61 and control mechanism 62, said laser mechanism 61 can process the processing of pattern painting templates, and said control mechanism 62 can change the color of spray paint;

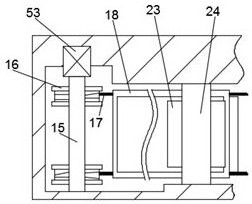

[0025] The stabilizing mechanism 60 includes a transmission mechanism 59 capable of transporting and large-area plastic-sprayed auto parts. The rear end wall of the functional cavity 58 is fixedly connected with two left and right moving motors 53, and the moving motor 53 is powere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com