Solar cell based on energy level adjustable nickel oxide hole transport layer and preparation method

A technology of hole transport layer and solar cell, applied in nanotechnology, circuit, photovoltaic power generation, etc. for materials and surface science, can solve the problems of difficult dispersion and control of nanoparticles, achieve good dispersion and prevent recombination , The effect of improving the hole transport characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

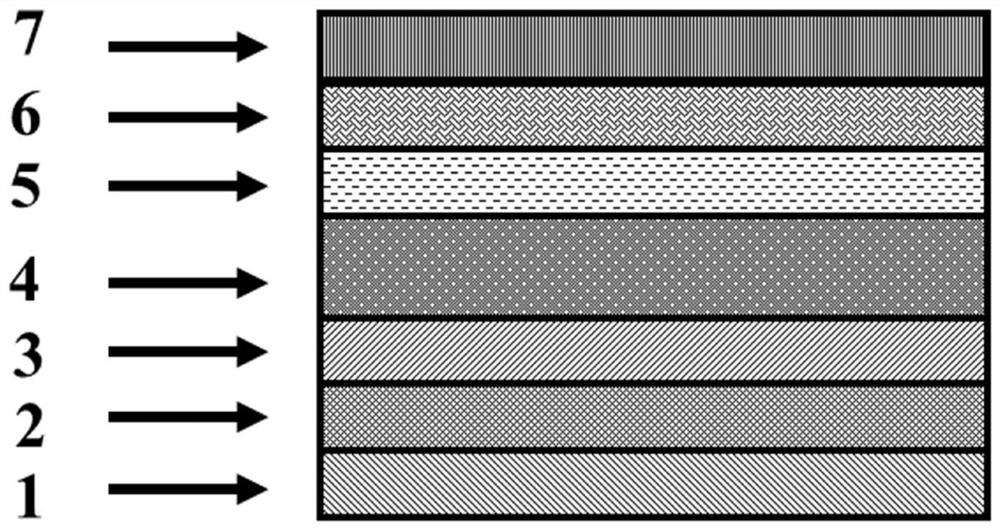

[0040] The present invention also provides a method for preparing a trans-lead-based perovskite solar cell based on a highly dispersed nickel oxide nanoparticle hole transport layer that can be stably synthesized in a wide pH range and has an adjustable energy level. Include the following steps:

[0041] Step 1: preparing a nickel oxide nanoparticle dispersion;

[0042] (1) 40~50mmol nickel nitrate hexahydrate is dissolved in 100mL deionized water; 4 parts of dark green precursor solutions are prepared, then use 25% 4 methyl ammonium hydroxide aqueous solution, 4 ethyl ammonium hydroxide aqueous solution, 4 Propyl ammonium hydroxide aqueous solution and 4 butyl ammonium hydroxide aqueous solution are used to adjust the pH value of the precursor solution to obtain the precursor solution;

[0043] (2) Aging the precursor solution for 12 hours, centrifuging the obtained precipitate at a centrifugal rate of 5000-7000rmp / s for 5-10min; washing with deionized water for 5 times, and...

Embodiment 1

[0070] Step 1: preparing a nickel oxide nanoparticle dispersion;

[0071] (1) 40~50mmol nickel nitrate hexahydrate is dissolved in 100mL deionized water; the dark green precursor solution is prepared, and then the pH value of the precursor solution is adjusted to 4~7 with 25% 4 methyl ammonium hydroxide aqueous solution respectively to obtain Precursor solution;

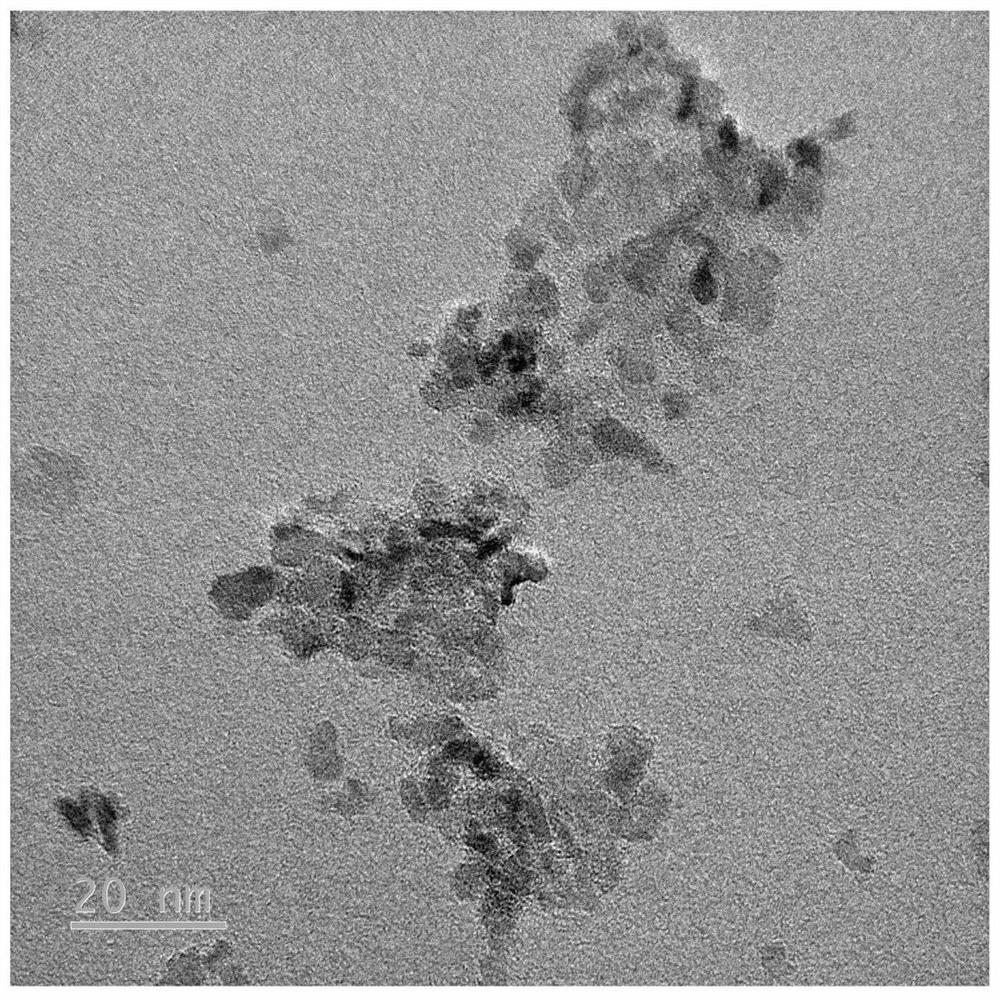

[0072] (2) Aging the precursor solution for 12 hours, centrifuging the obtained precipitate at a centrifugal rate of 5000-7000rmp / s for 5-10min; washing with deionized water for 5 times, and drying the obtained product in a vacuum drying oven, The vacuum drying temperature is 80-100° C., and the drying time is 10-24 hours; after the dried product is obtained, the dried product is ground and placed in a muffle furnace for sintering at 200-400° C. for 30-120 minutes. The calcined product is nickel oxide nanoparticles (NiOx:TMAOH).

[0073] The obtained nickel oxide nanoparticles are dispersed in deionized water or it...

Embodiment 2

[0090] Step 1: preparing a nickel oxide nanoparticle dispersion;

[0091] (1) 40~50mmol nickel nitrate hexahydrate is dissolved in 100mL deionized water; the dark green precursor solution is prepared, and then the pH value of the precursor solution is adjusted to 4~7 with 25% 4 ethyl ammonium hydroxide aqueous solution respectively to obtain Precursor solution;

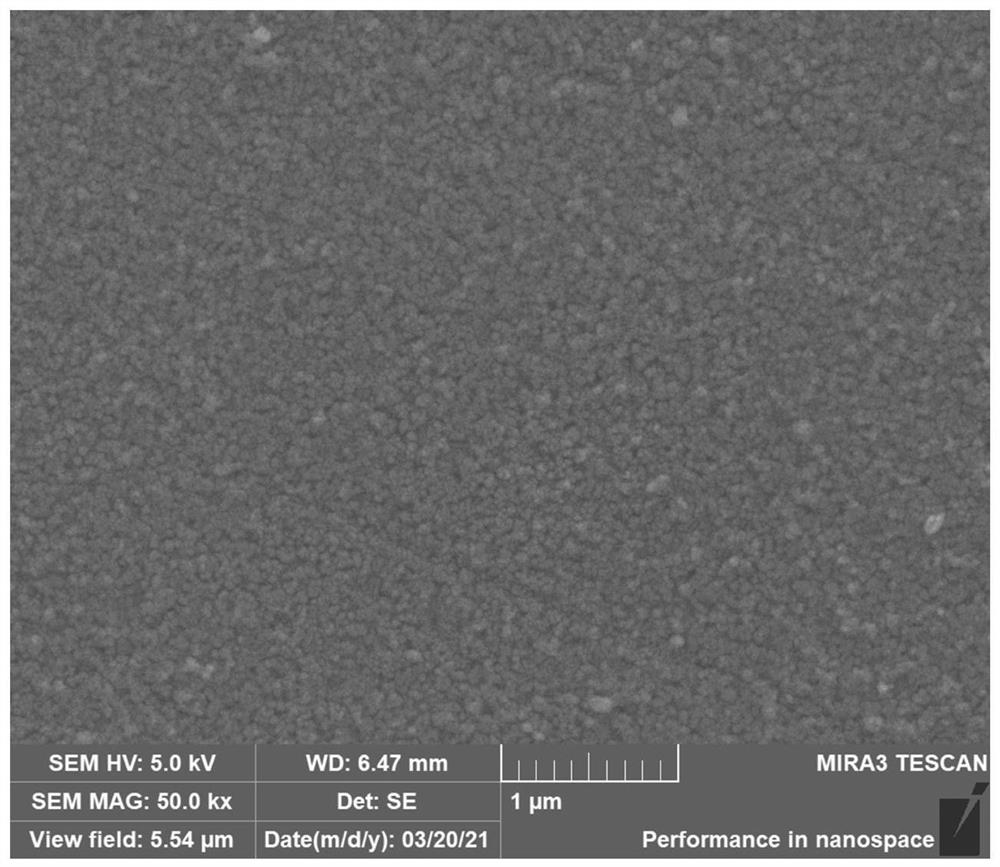

[0092] (2) Aging the precursor solution for 12 hours, centrifuging the obtained precipitate at a centrifugal rate of 5000-7000rmp / s for 5-10min; washing with deionized water for 5 times, and drying the obtained product in a vacuum drying oven, The vacuum drying temperature is 80-100° C., and the drying time is 10-24 hours; after the dried product is obtained, the dried product is ground and placed in a muffle furnace for sintering at 200-400° C. for 30-120 minutes. The calcined product was nickel oxide nanoparticles (NiOx:TEAOH).

[0093] Step 3: preparing a nickel oxide nanoparticle hole transport layer.

[0094] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com