Polymer Clean Drilling Fluid System

A polymer and amine polymer technology, applied in the field of petroleum drilling aids, can solve problems such as wellbore instability, and achieve the effects of wellbore cleanliness, good comprehensive performance, and good fluid loss reduction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

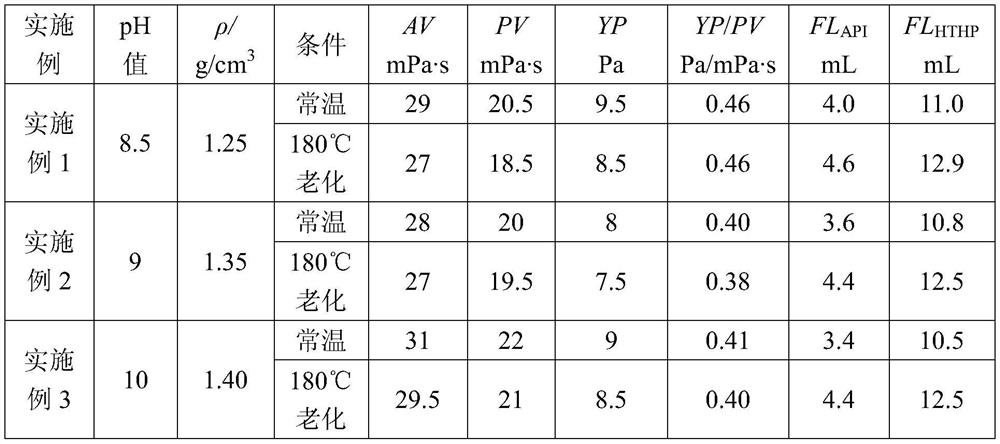

Embodiment 1

[0023] Embodiment 1: polymer cleaning drilling fluid system (i.e. cleaning type polymer drilling fluid system) of the present invention is made by the raw material of following mass ratio: 1000 parts of tap water, 40 parts of bentonite, 2 parts of sodium carbonate , 0.6 parts of sodium hydroxide, 12 parts of fluid loss reducer, 17 parts of wall-fixing agent, 5 parts of coating agent, 6 parts of polyanionic cellulose, 9 parts of high temperature and salt-resistant fluid loss reducer, 12 parts of lubrication inhibitor, drilling 22 parts of solid lubricant for liquid, 6 parts of solid lubricant graphite, 43 parts of KCl, 2 parts of gel plugging agent, 12 parts of superfine calcium carbonate powder, weighting agent barite powder, the amount of weighting agent should meet the adjusted mud density up to 1.20g / cm 3 requirements.

[0024] The main component of the fluid loss control agent is cucurbituril[n]-amine salt polymer microspheres, n=5, cucurbituril[n] is cucurbituril[5], and...

Embodiment 2

[0032] Embodiment 2: The polymer cleaning drilling fluid system of the present invention is made of the raw materials of the following mass ratio: 1000 parts of tap water, 35 parts of bentonite, 2.5 parts of sodium carbonate, 0.8 part of sodium hydroxide, fluid loss reducer 15 parts of agent, 18 parts of wall-fixing agent, 4 parts of coating agent, 7 parts of polyanionic cellulose, 10 parts of high temperature anti-salt fluid loss reducer, 15 parts of lubrication inhibitor, 25 parts of solid lubricant for drilling fluid, solid lubricant 9 parts graphite, 48 parts KCl, 2.5 parts gel plugging agent, 14 parts superfine calcium carbonate powder, weighting agent barite powder, the amount of weighting agent should meet the mud density after adjustment to 1.30g / cm 3 requirements.

[0033] The main component of the fluid loss control agent is cucurbituril[n]-amine salt polymer microspheres, n=6, cucurbituril[n] is cucurbituril[6], and the amine salt is 1,5-diaminopentane Dihydrochlor...

Embodiment 3

[0035] Embodiment 3: The polymer cleaning drilling fluid system of the present invention is made of the raw materials of the following mass ratio: 1000 parts of tap water, 40 parts of bentonite, 2.8 parts of sodium carbonate, 1 part of sodium hydroxide, fluid loss reducer 15 parts of agent, 19 parts of wall-fixing agent, 5 parts of coating agent, 8 parts of polyanionic cellulose, 10 parts of high temperature anti-salt fluid loss reducer, 14 parts of lubrication inhibitor, 24 parts of solid lubricant for drilling fluid, solid lubricant 10 parts of graphite, 49 parts of KCl, 3 parts of gel plugging agent, 15 parts of superfine calcium carbonate powder, weighting agent barite powder, the amount of weighting agent should meet the mud density after adjustment to 1.40g / cm 3 requirements.

[0036] The main component of the fluid loss control agent is cucurbituril[n]-amine salt polymer microspheres, n=7, cucurbituril[n] is cucurbituril[7], and amine salt is 1,1-dimethyl- 4,4'-bipyrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com