Carbon nanotube, device and method for preparing hydrocarbon by catalytic cracking through circulating intermittent pushing method

A technology of hydrocarbons and carbon nanotubes, applied in the direction of carbon nanotubes, carbon compounds, chemical instruments and methods, etc., can solve the problem that the cracking time of carbon source gas cannot be precisely controlled, and achieve simple structure, complete reaction and less impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

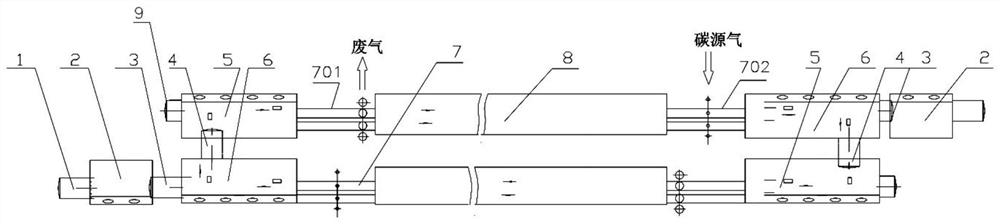

[0044] Such as figure 1 , 5 , Shown in 6, a kind of device of the catalytic cracking hydrocarbon of a kind of circulation type intermittent push method:

[0045] It includes two end-to-end push generation units, and the push generation unit is composed of a feeding glove box 5, a tube furnace 8, a receiving glove box 6, and a discharging glove box 6, wherein the feeding glove box 5, the tube furnace Type furnace 8 and receiving glove box 6 are sequentially sealed and connected, and receiving glove box 6 is sealed and connected with discharging glove box 2 through connecting transition cabin 3; They are all sealed and connected with the feeding glove box 5 of the other transfer generation unit through a transfer transition chamber 4, thereby forming a closed closed loop connected end to end; inside the two transfer generation units, there are multiple carriers containing catalysts. With intermittent shifting, controlling the passing time of the carrier in the tube furnace 8 c...

Embodiment 2

[0058] Such as figure 1 , 5 , Shown in 6, a kind of device of the catalytic cracking hydrocarbon of a kind of circulation type intermittent push method:

[0059]It includes two end-to-end push generation units, and the push generation unit is composed of a feeding glove box 5, a tube furnace 8, a receiving glove box 6, and a discharging glove box 6, wherein the feeding glove box 5, the tube furnace Type furnace 8 and receiving glove box 6 are sequentially sealed and connected, and receiving glove box 6 is sealed and connected with discharging glove box 2 through connecting transition cabin 3; They are all sealed and connected with the feeding glove box 5 of the other transfer generation unit through a transfer transition chamber 4, thereby forming a closed closed loop connected end to end; inside the two transfer generation units, there are multiple carriers containing catalysts. With intermittent shifting, controlling the passing time of the carrier in the tube furnace 8 ca...

Embodiment 3

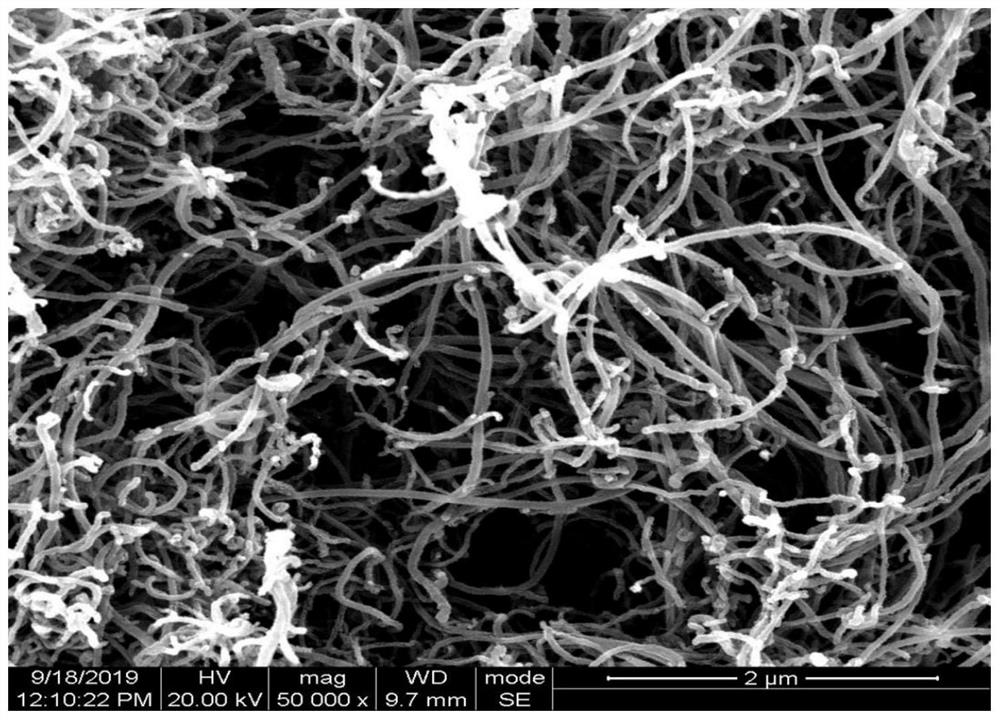

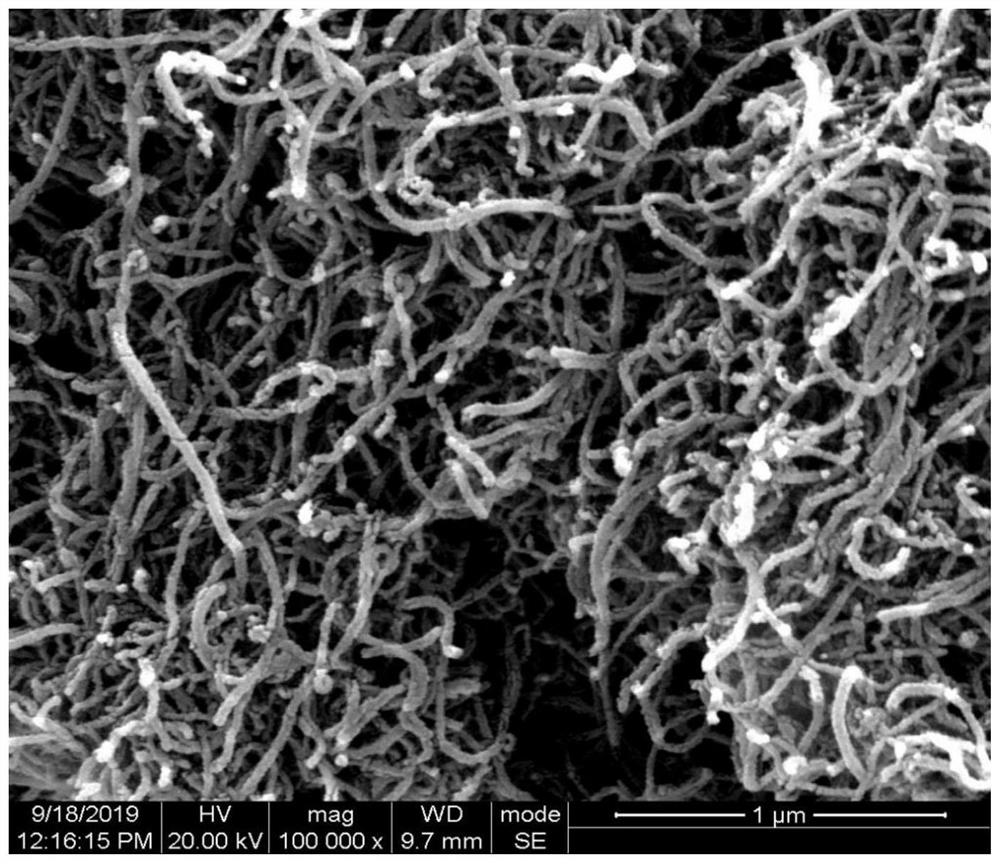

[0084] Embodiment 3 and embodiment 2 device, method, implementation steps are all the same, the difference is that the cracking furnace tube 7 of embodiment 3 is arranged in three or two, and the carbon source gas in each cracking furnace tube 7 The flow rate is 4.5m 3 / h, the diameter of the finally prepared carbon nanotubes is mainly distributed between 30-50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com