High-shrinkage biaxially-oriented polylactic acid film and preparation method thereof

A technology of biaxial stretching and polylactic acid, which is applied in chemical instruments and methods, flat products, and other household appliances, etc., can solve the problems that cannot be applied in the field of cigarette packaging, general performance of biaxially stretched polylactic acid, etc., and achieve mechanical properties Excellent, good gloss and flatness, effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

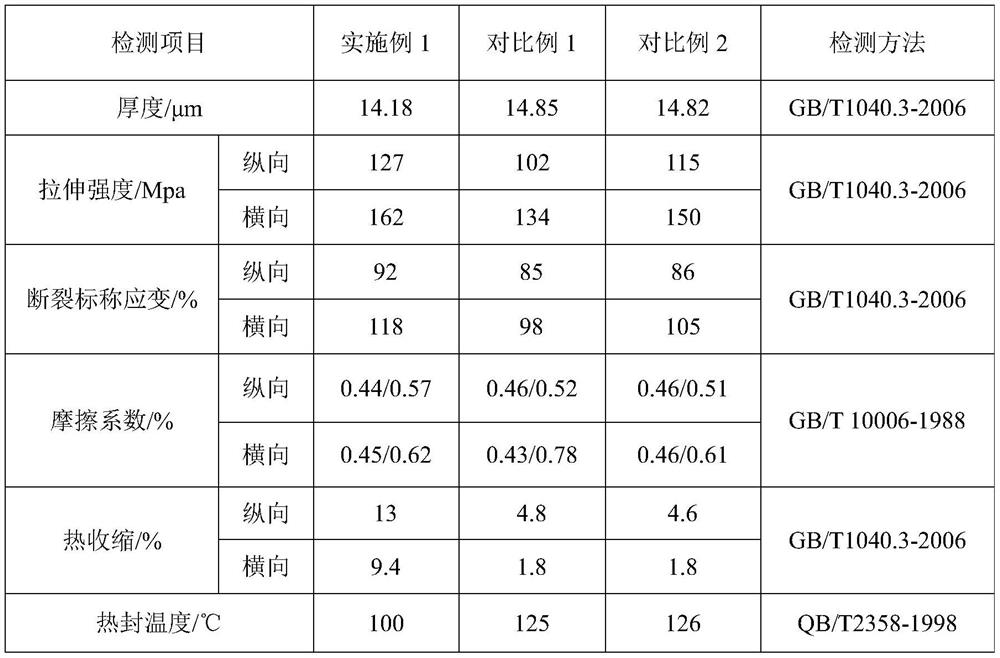

Examples

Embodiment 1

[0031] A high-shrinkage biaxially oriented polylactic acid film, which sequentially includes a surface layer I, a core layer, and a surface layer II; the surface layer I and the surface layer II are made of the following raw materials in parts by mass: 97.5 parts of heat-sealing compound, 2.5 parts of anti-adhesive masterbatch, wherein , the heat-sealing material is polylactic acid resin I; the core layer is made of the following raw materials in parts by mass: 95.5 parts of polylactic acid resin II, 1.5 parts of antistatic masterbatch, and 3 parts of smooth masterbatch; among them, the antisticking masterbatch includes The following mass percentages of raw materials: polylactic acid resin II 97%, silicon dioxide 3%; antistatic masterbatch includes the following mass percentages of raw materials: polylactic acid resin II 97%, ethoxylated alkylamine 3%; smooth masterbatch The raw materials include the following mass percentages: polylactic acid resin II 99%, oleic acid amide 1%;...

Embodiment 2

[0039] A high-shrinkage biaxially oriented polylactic acid film, which sequentially includes a surface layer I, a core layer, and a surface layer II; the surface layer I and the surface layer II are made of the following raw materials in parts by mass: 97 parts of heat-sealing material, 3 parts of anti-adhesive masterbatch, wherein , the heat-sealing material is polylactic acid resin I; the core layer is made of the following raw materials in parts by mass: 93 parts of polylactic acid resin II, 3 parts of antistatic masterbatch, and 4 parts of smooth masterbatch; wherein, the antisticking masterbatch includes the following Raw materials in mass percentage: polylactic acid resin II 96%, silicon dioxide 4%; antistatic masterbatch includes the following raw materials in mass percentage: polylactic acid resin II 96%, ethoxylated alkylamine 4%; smooth masterbatch includes The raw materials in the following mass percentages: polylactic acid resin II 98.5%, oleic acid amide 1.5%; poly...

Embodiment 3

[0047] A high-shrinkage biaxially oriented polylactic acid film, which sequentially includes a surface layer I, a core layer, and a surface layer II; the surface layer I and the surface layer II are made of the following raw materials in parts by mass: 99 parts of heat-sealing compound, 1 part of anti-adhesive masterbatch, wherein , the heat-sealing material is polylactic acid resin I; the core layer is made of the following raw materials in parts by mass: 96 parts of polylactic acid resin II, 1 part of antistatic masterbatch, and 3 parts of smooth masterbatch; wherein, the anti-adhesive masterbatch includes the following Raw materials in mass percentage: polylactic acid resin II 98%, silicon dioxide 2%; antistatic masterbatch includes the following raw materials in mass percentage: polylactic acid resin II 98%, ethoxylated alkylamine 2%; smooth masterbatch includes The raw materials in the following mass percentages: polylactic acid resin II 99.5%, oleic acid amide 0.5%; polyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com