Apparatus for applying paint and paint on the surface of automotive interior parts made of rattan wood veneer

A technology for automotive interior parts and pigments, which is used in manufacturing tools, wood treatment, wood processing appliances, etc., can solve the problems of lack of grain, affect the appearance, unnatural wood grain, etc., to achieve the real wood grain on the surface and improve the color fastness. , The effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Describe the present invention in further detail below in conjunction with accompanying drawing:

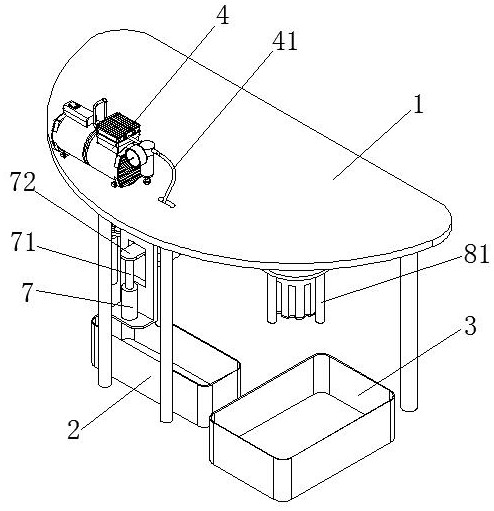

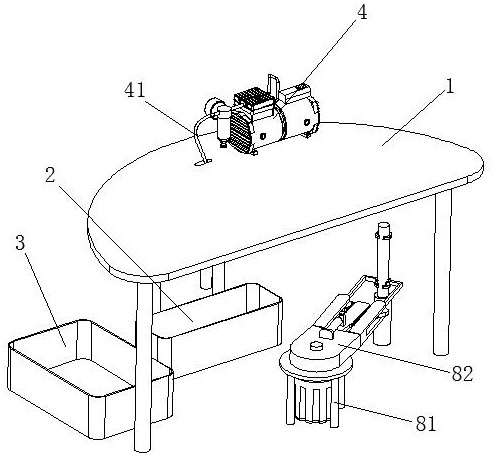

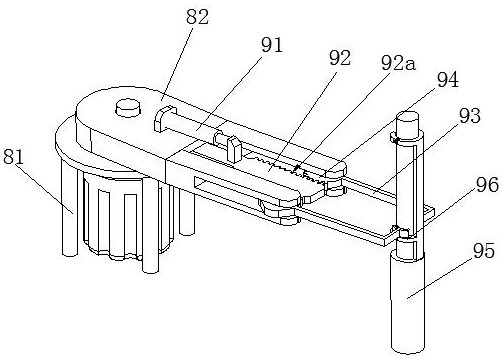

[0031] Such as Figure 1 to Figure 10 Shown, a kind of rattan veneer system automotive interior parts surface pigment paint coloring device, comprises fixed frame 1, paint box 2 and finished product box 3, described fixed frame 1 is fixed with vacuum device 4, and this vacuumizes A hollow hose 41 is connected to the device 4, and the lower end of the hollow hose 41 communicates with the connecting head 5 that can be raised and lowered. The connecting head 5 is provided with a sealing assembly that can close or open the internal passage of the connecting head; The paint box 2 is provided with a transfer mechanism for transferring rattan wood, and the transfer mechanism is provided with a clamping mechanism for clamping rattan wood; the sealing assembly includes several sealing plates 61 capable of forming a sealing surface, A corresponding number of racks 62, a correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com