High-precision numerical control machine tool machining all-in-one machine

A CNC machine tool, high-precision technology, applied in metal processing mechanical parts, metal processing, metal processing equipment and other directions, can solve the problems of inability to achieve automatic production, lack of smoothness, precision, and manual operation for cutting materials, saving time. , avoid machining deviation and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

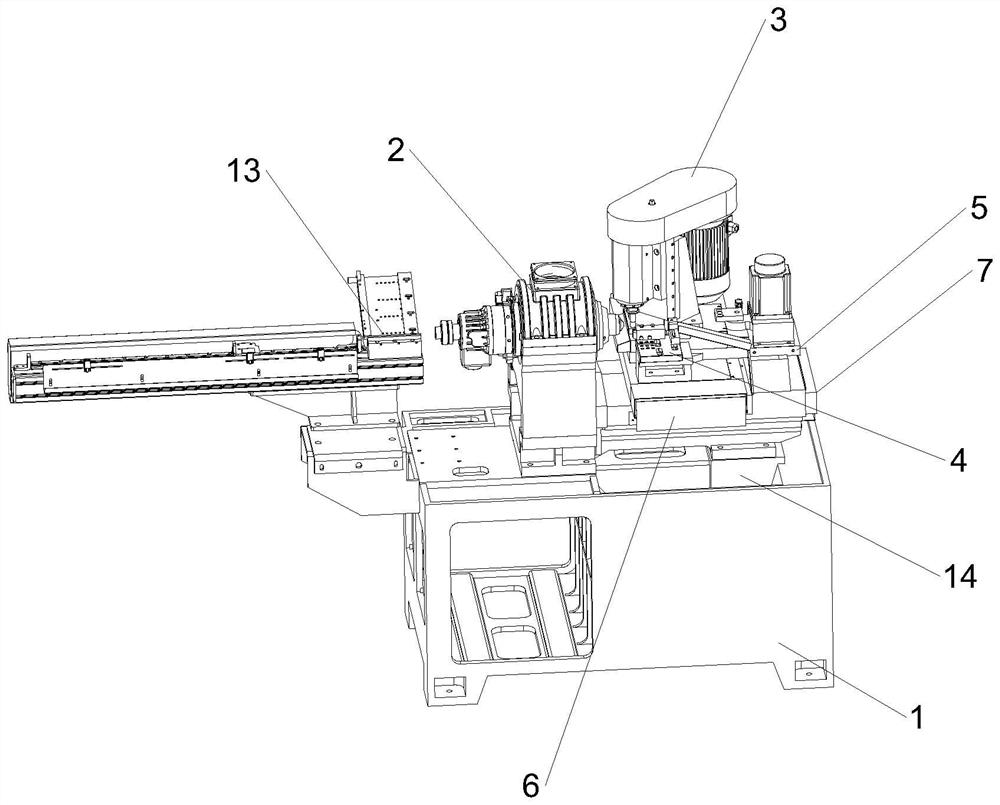

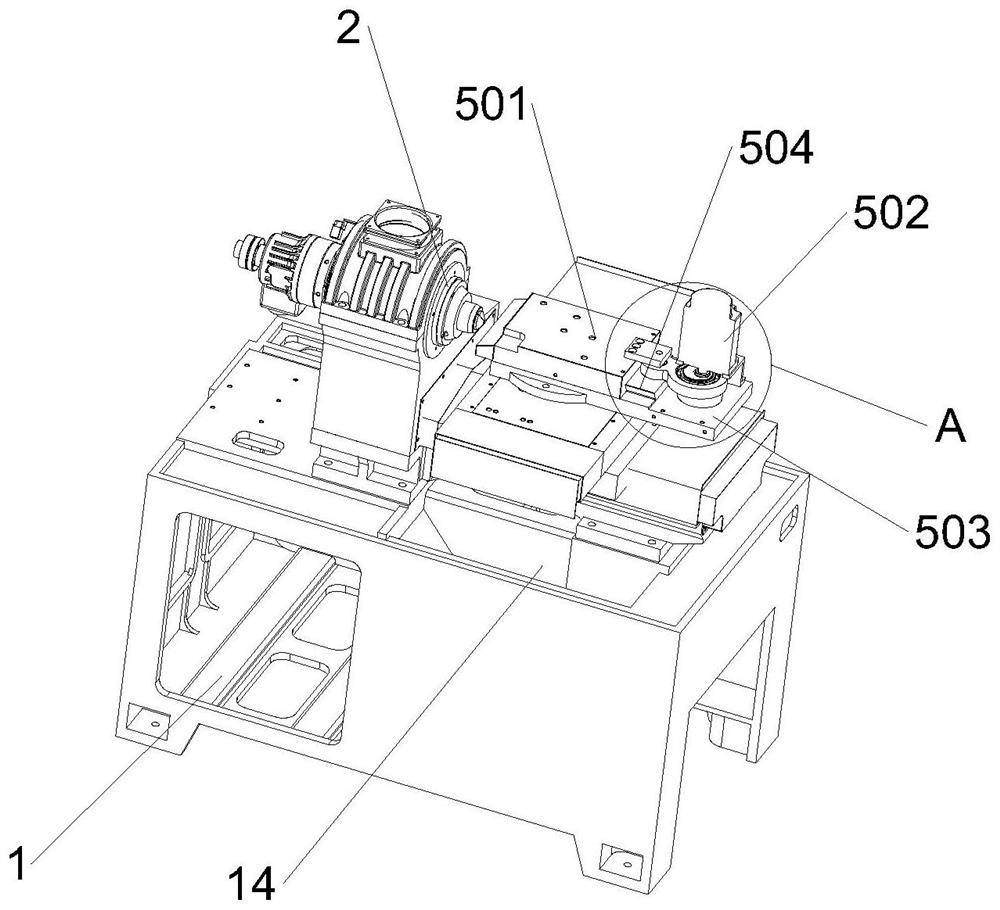

[0037] see Figure 1-Figure 8 As shown, a high-precision CNC machine tool processing integrated machine includes a machine frame 1 and a headstock 2. The headstock 2 is fixed on the upper surface of the machine frame 1. The headstock 2 adopts an electric spindle, which has high precision and fast speed, and can effectively To save product processing time, there is a blanking rack 13 on one side of the spindle box 2, which can be adjusted and replaced according to the processing requirements and specifications of the product, and the outlet end of the blanking rack 13 is located on the same axis as the central axis of the spindle box 2 At the position, the workpiece at the lowest end of the unloading frame 13 can be pushed into the spindle box 2 through a mechanism such as a chain plate, without manual loading and clamping, and the automation of the loading process during processing is realized. The shaft 7 and the third sliding shaft 7 are located on the other side of the head...

Embodiment 2

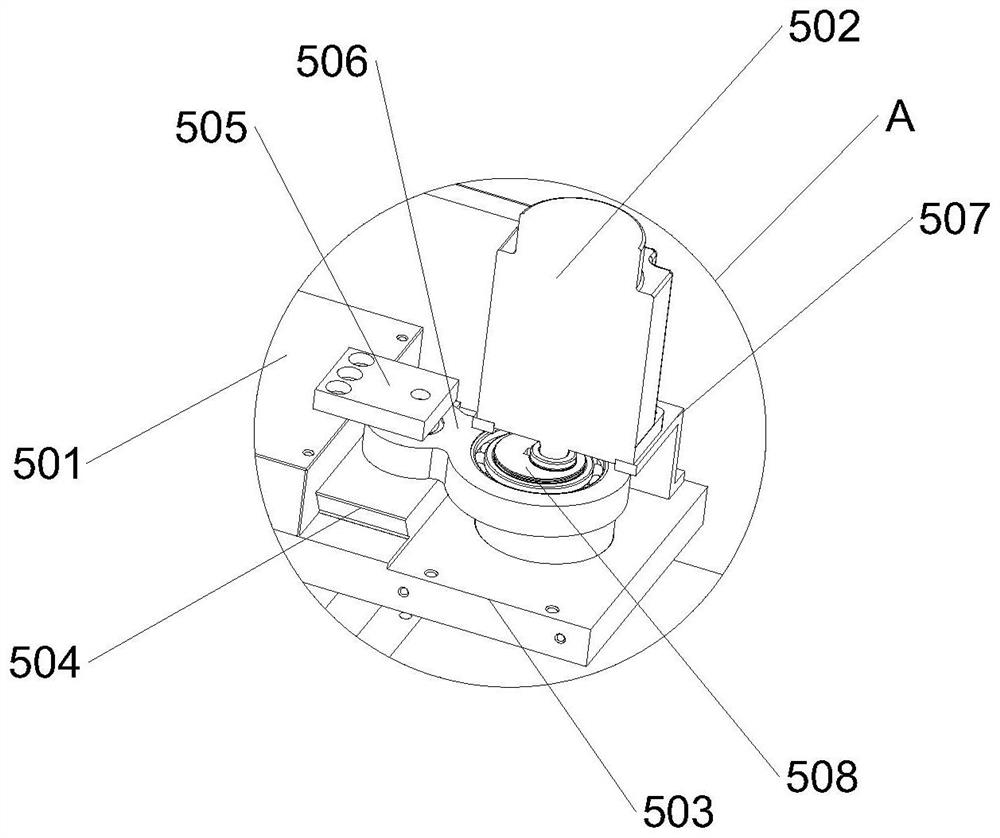

[0040] When machining with turning tool, the workpiece rotates at a high speed driven by the spindle. At this time, when the turning tool contacts the workpiece, it will generate a large vibration to the turning tool and will have a large impact on the turning tool during subsequent cutting. At this time, if the turning tool is not fixed firmly, it will easily cause the turning tool to vibrate or shift, resulting in insufficient surface finish and precision of the product. In addition, due to the technical characteristics of the turning tool that needs to be replaced, the turning tool cannot be used permanently during installation. installation method.

[0041] see Figure 9-Figure 11 As shown, a high-precision CNC machine tool processing integrated machine includes a machine frame 1 and a headstock 2. The headstock 2 is fixed on the upper surface of the machine frame 1. The headstock 2 adopts an electric spindle, which has high precision and fast speed, and can effectively T...

Embodiment 3

[0044] In order to improve the effect of automatic production and avoid the situation that the processing process is automatic but the loading and unloading process still needs to be done manually, after the processing is completed, the machine tool can be controlled to complete the automatic blanking work to realize the automation of the blanking process.

[0045] see Figure 9-Figure 11 As shown, a high-precision CNC machine tool processing integrated machine includes a machine frame 1 and a headstock 2. The headstock 2 is fixed on the upper surface of the machine frame 1. The headstock 2 adopts an electric spindle, which has high precision and fast speed, and can effectively To save product processing time, there is a blanking rack 13 on one side of the spindle box 2, which can be adjusted and replaced according to the processing requirements and specifications of the product, and the outlet end of the blanking rack 13 is located on the same axis as the central axis of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com