Application of variable-frequency microwaves in drying and curing of gluing material coating of electronic product

A technology for gluing materials and electronic products, applied in coatings, devices for coating liquids on surfaces, pre-treating surfaces, etc., can solve problems such as focus formation, air bubbles, material overheating, and heating process that is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

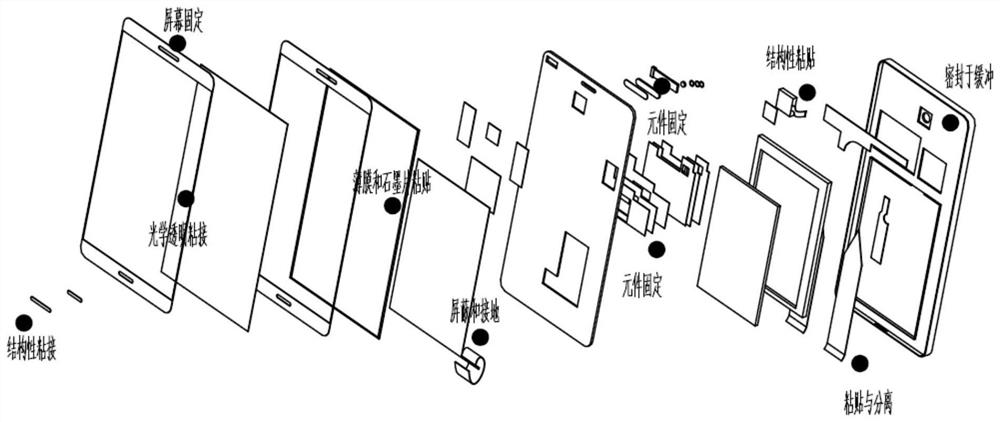

[0023] Hereinafter, the glass material back shell and metal border structural bonding are set up in conjunction with mobile phone production.

[0024] Step 1: The coating (example is an epoxy) and is attached to the metal border over the metal border over the glue-monitoring back shell, and the edge is overlapped;

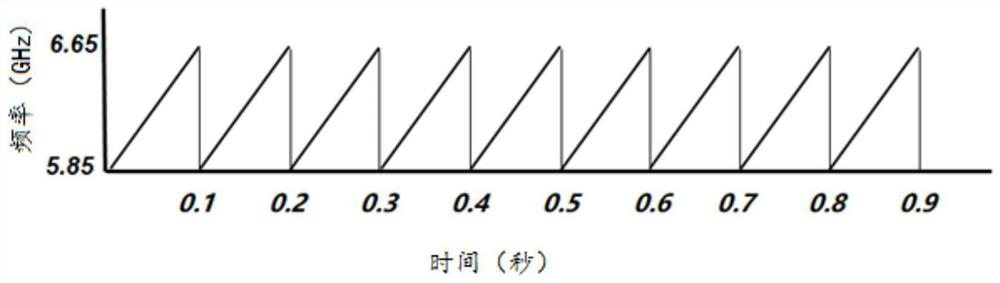

[0025] Step 2: Secure the glued back shell and the border using the fixture and apply pressure on the glue wire. The structural assembly assembly and the clamp in the holding state are placed on the conveyor belt, conveyed into the variable frequency microwave heating furnace, and the variable frequency microwave heating furnace can generate a variable frequency microwave, the present embodiment C-band microwave (eg figure 2 Indicated by it);

[0026] Step 3: For different grades of glue, select the corresponding warming program, start the microwave heating furnace, produce high-speed change electromagnetic fields, acting on the glue material coating. The process is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com