Hub motor winding capable of dissipating heat easily

A technology for in-wheel motors and windings, which is applied to the shape/style/structure of electrical components, winding conductors, electrical components, etc., can solve the problems of long heat conduction path, low heat dissipation efficiency of motors, and many types of materials, and achieves improved power and rotation. moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

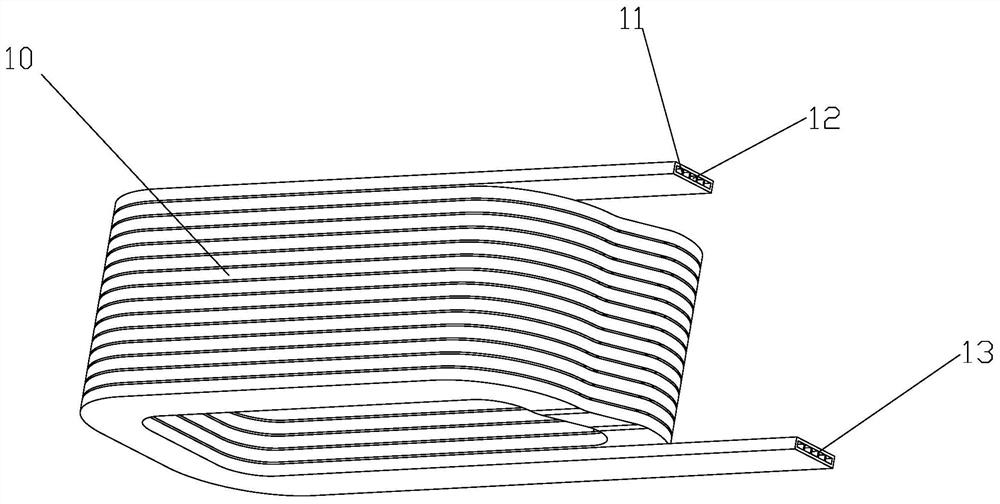

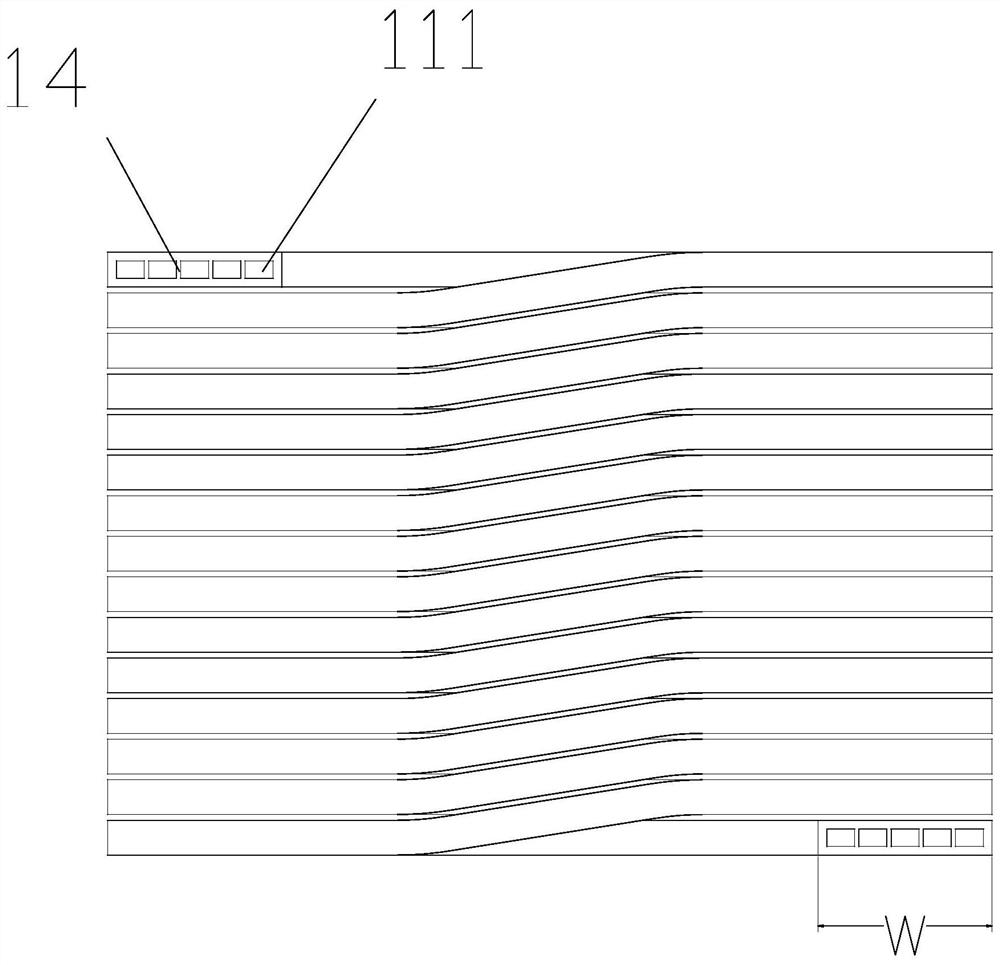

[0014] see Figure 1-3 , this embodiment provides a wheel hub motor winding that is easy to dissipate heat, including a winding body 10, the winding body 10 is bent into multiple layers along itself, and a cooling liquid channel 11 is opened inside the winding body 10, and the cooling liquid channel 11 runs along the length of the winding body The direction runs through both ends of the winding body. One of the two ends of the winding body 10 is the cooling liquid inlet 12 , and the other end is the cooling liquid outlet 13 .

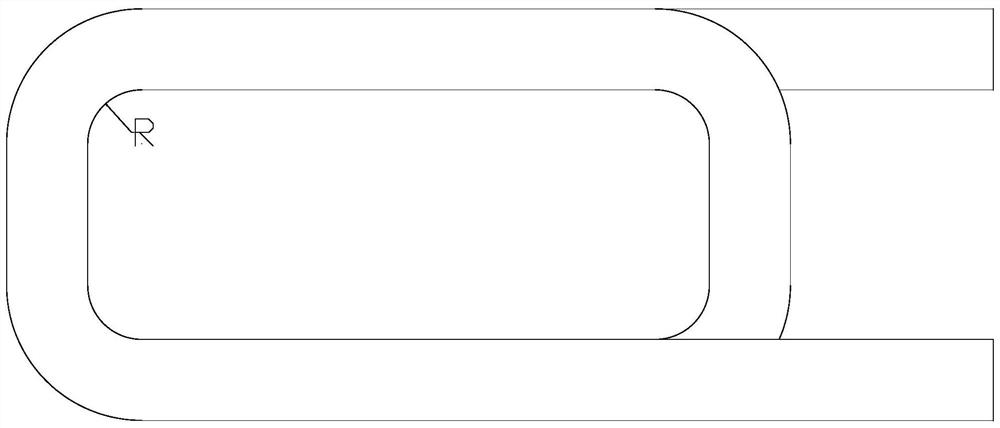

[0015] Specifically, the winding body 10 is bent into a rectangular structure with an inner bending angle and an outer bending angle formed at the bending position. Preferably, the radius of the inner bending angle R is greater than half of the width W of the winding body one.

[0016] Specifically, the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com