Omnidirectional matching non-uniform energy receiving surface for line source radiation

An energy-receiving, non-uniform technology, applied in the radiating element structure, antenna-grounding switch structure connection, antenna and other directions, can solve the problems of unsatisfactory receiver performance, reduced receiving efficiency of receiving metasurface, and deterioration of impedance mismatch, etc. Excellent performance, light weight and improved absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

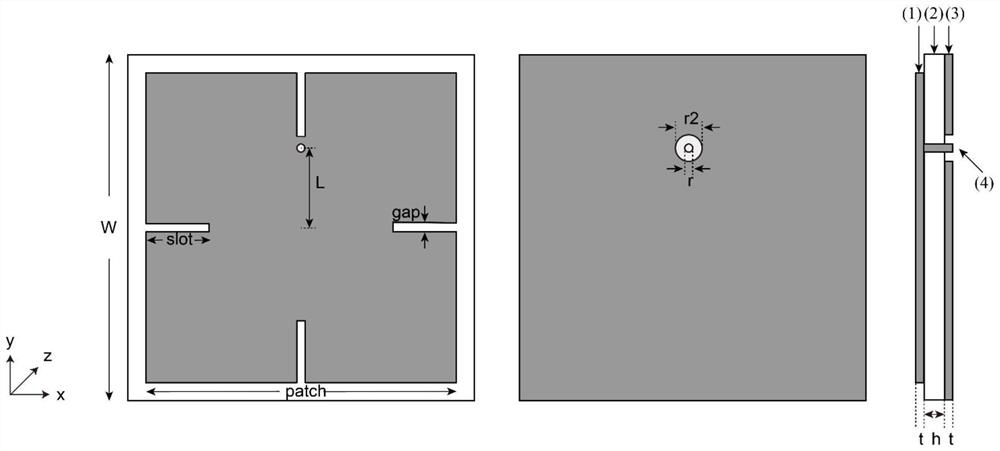

[0035] like figure 1 As shown, the non-uniform surface is mainly composed of square sub-wavelength resonant units whose unit size is less than 1 / 4 of the working wavelength, which can be regarded as a uniform medium. Each sub-wavelength resonant unit is mainly composed of the first metal copper sheet 1, The first dielectric layer 2 and the second metal copper sheet 3 are composed of the first metal copper sheet 1 and the second metal copper sheet 3 in the shape of square sheets, the first metal copper sheet 1 and the second metal copper sheet 3 have the same thickness, and the first metal copper sheet 1 and the second metal copper sheet 3 have the same thickness. The side length of the metal copper sheet 1 is less than the side length of the second metal copper sheet 3, the first dielectric layer 2 is a square block, the thickness of the first dielectri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com