Sea-land connector box for low-temperature environment and installation method

A low-temperature environment, joint box technology, applied in the direction of light guide, optics, instruments, etc., to achieve the effect of increasing tensile strength, isolating water vapor, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

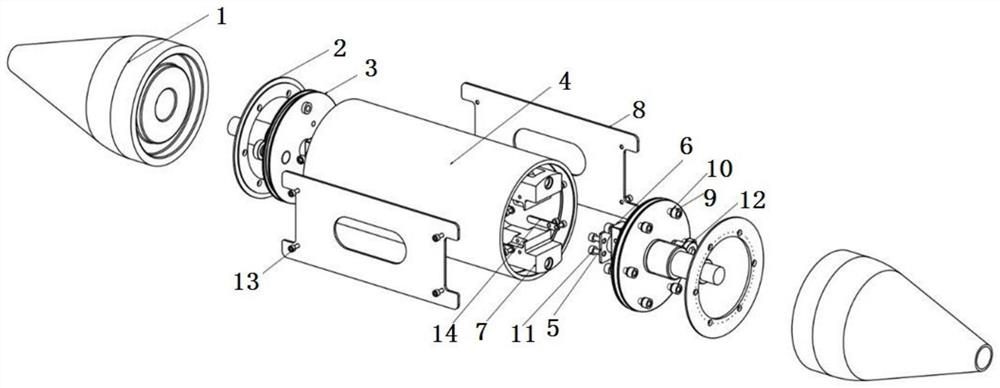

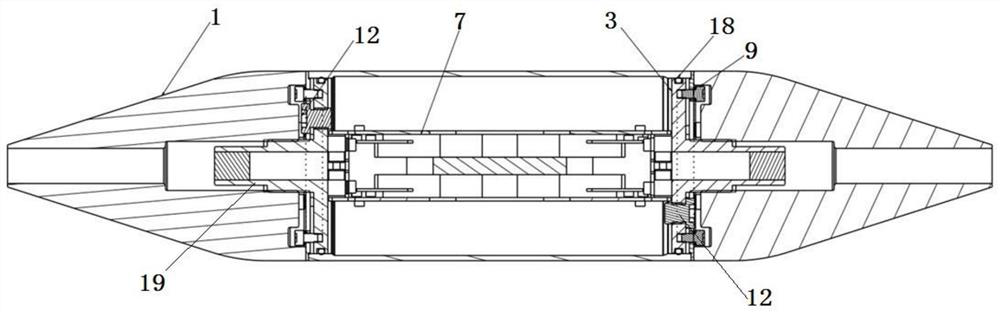

[0050] Such as figure 1 , 2As shown in , 5, the sea-land joint box for low temperature environment includes a fiber optic box 7, a pressure-resistant cylinder 4 and sealing end caps 3 at both ends of the pressure-resistant cylinder. The sealed end cover at the end is connected into the fiber optic box; the sealing process is performed between the sealed end cover and the pressure-resistant cylinder, and between the sealed end cover and the optical cable. Oil plug plug 12 is arranged.

[0051] The outer surfaces of the two sealed end caps are respectively provided with cable end protective sleeves 1, and the interior of the cable end protective sleeves is provided with a through hole for the optical cable to pass through. The outer surface of the sealed end caps is provided with an extension 19. The end protection sleeve is screwed into one body through the extension part and the through hole. The contact surface between the extension part and the inner wall of the through h...

Embodiment 2

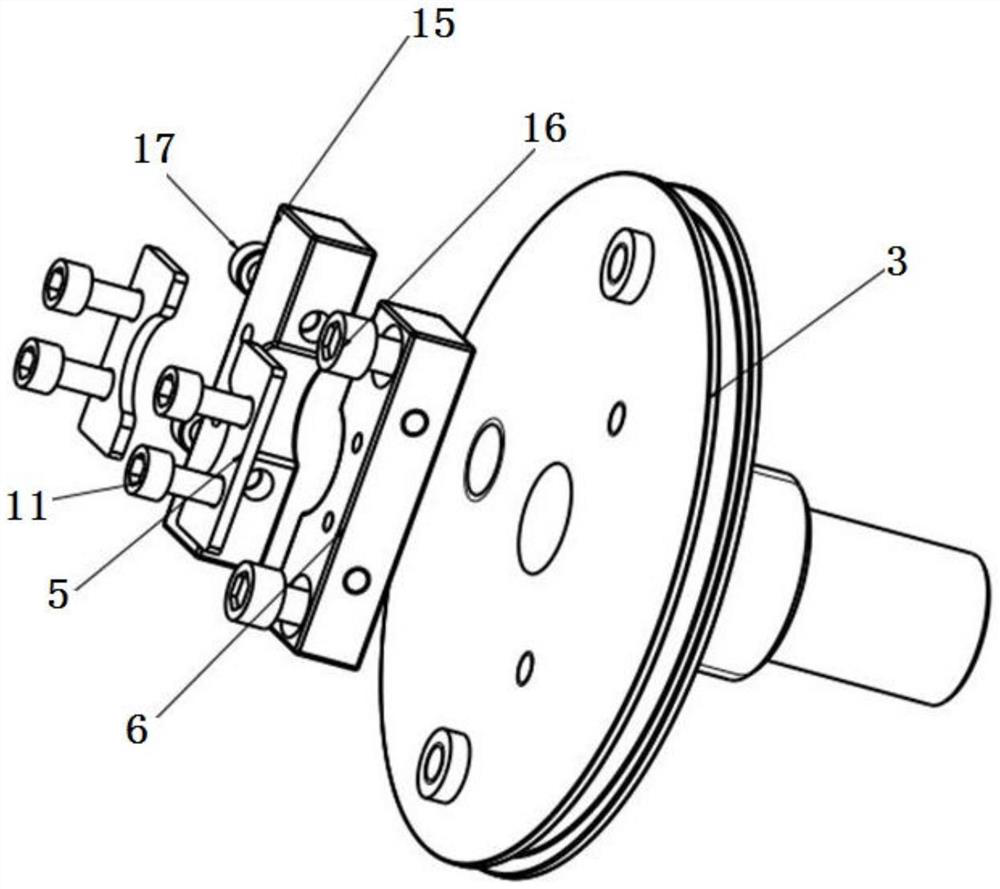

[0059] On the basis of Example 1, such as image 3 As shown, there is an optical cable fixing device inside the sealing end cover, including a cable end fixing piece 6, a cable end locking piece 15, and two anchor pieces 5; the cable end fixing piece, the cable end locking piece, and the anchor piece are in contact with the optical cable There are curved grooves everywhere.

[0060] The cable end fixing part and the cable end locking part are in a half-open structure. The cable end fixing part is fixed on the inner side of the sealing end cover through the fixing screw 16, and the cable end locking part is connected with the cable end fixing part through the locking screw 17. Co-clamping secures the fiber optic cable.

[0061] Similarly, the two anchors have a half-open structure, and the two anchors anchor the cable armored steel wire layer between the cable end fixing piece, the outer surface of the cable end locking piece and the corresponding anchoring pieces through the ...

Embodiment 3

[0064] Such as figure 1 , 2 As shown, the end surface of the protective sleeve of the pressure-resistant cylinder is provided with a groove matching the locking screw of the limit ring to form a limit step surface for matching with the oil plug plug. The stopper is used to limit the position and enhance the sealing performance of the oil filling port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com