Mining optical cable protection sleeve repairing device

A technology for optical cable protection and mine use, which is applied in the field of mine optical cable protective cover repair devices, can solve the problems of deep damage to soft lines, long time consumption, and damage to the outer protective cover, etc., to achieve repair of damaged parts, easy material picking, and easy operation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

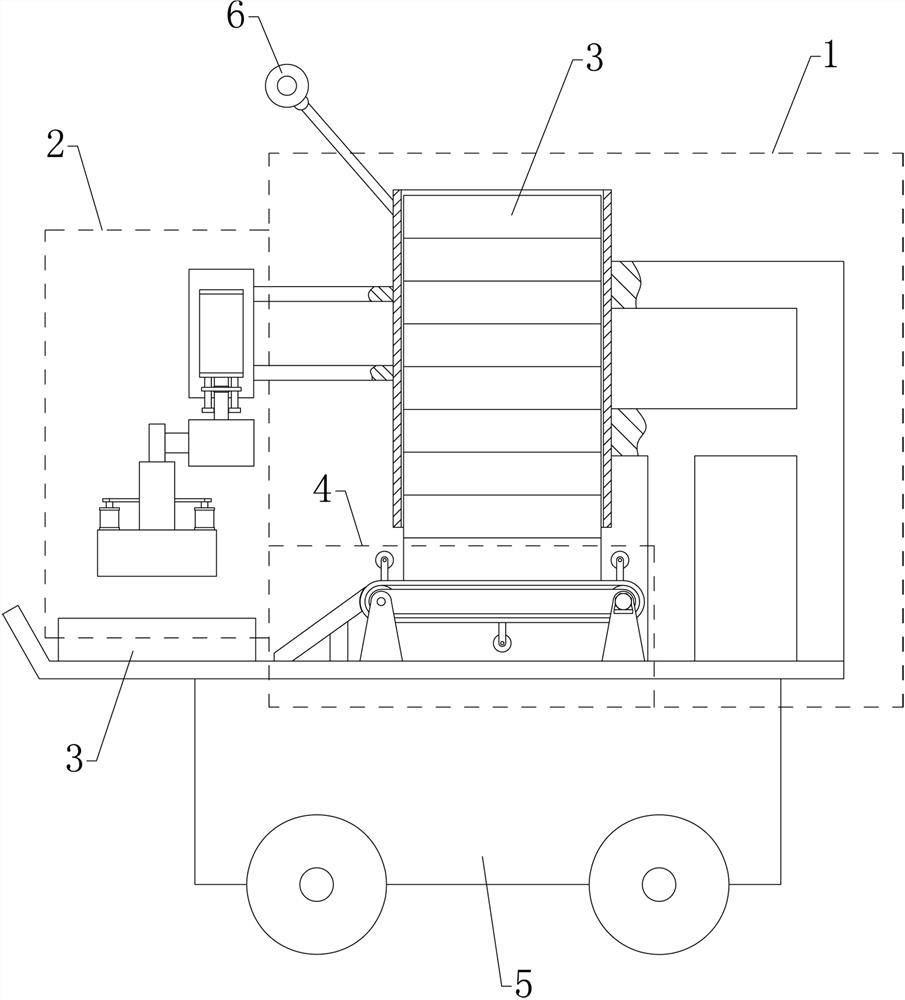

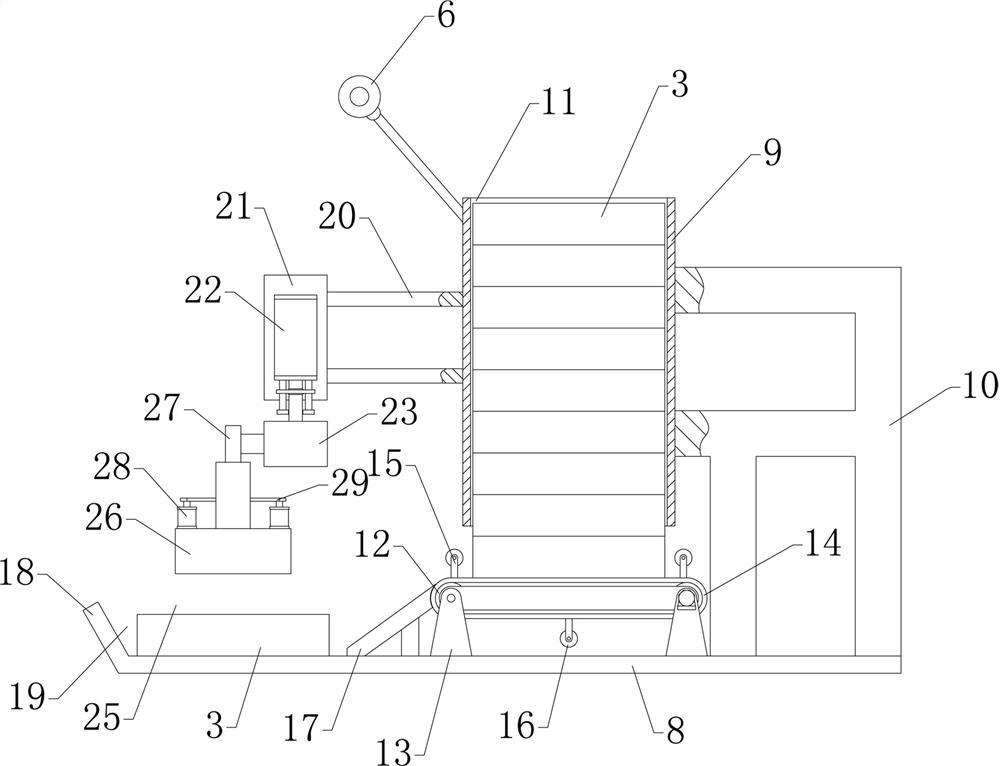

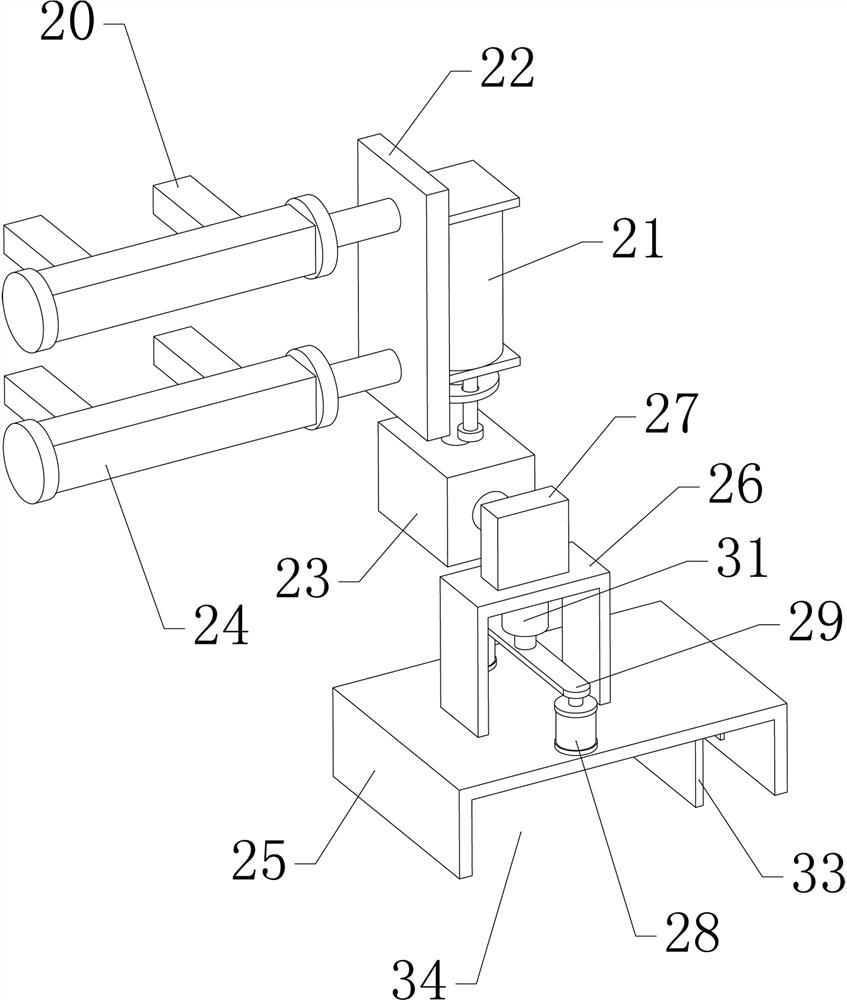

[0041] Such as Figure 1-10 As shown in the above, the mine optical cable protective cover repair device includes a mining remote inspection vehicle 5, and an intelligent monitoring camera 6 is fixedly installed on the top of the mining remote inspection vehicle 5, the intelligent monitoring camera 6, the mine The remote inspection vehicles 5 are all connected to the control center on the ground with signals, and also include a material storage and supply structure 1, a material picking and repairing structure 2, and a belt conveyor 4. There are several storage and supply structures inside the storage and supply st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com