Producing method of profile rod piece and assembling method of display screen

The technology of a production method and assembly method, which is applied in the field of display screens, can solve the problems of bulky frame structure, high cost, and inconvenient assembly of the display screen, and achieve the effect of low processing cost and heavy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

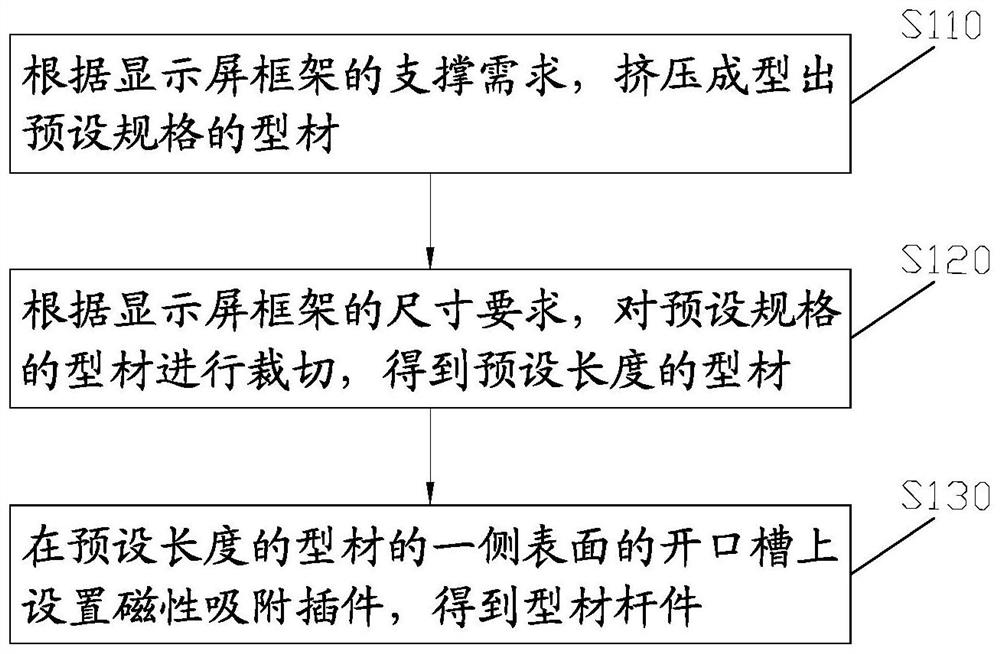

[0032] like figure 1 As shown, Embodiment 1 of the present invention provides a method for producing a profile bar, the production method comprising:

[0033] Step S110: According to the support requirements of the display screen frame, extruded profiles of preset specifications.

[0034] Specifically, a profile is an object with a certain geometric shape made of iron or steel and a material with certain strength and toughness through rolling, extrusion, casting and other processes. This kind of material has a certain appearance size, a certain shape of the section, and has certain mechanical and physical properties. Profiles can be used alone or further processed into other manufactured products, often used in building structures and manufacturing installations. The mechanical engineer can select the specific shape, material, heat treatment state, mechanical properties and other parameters of the profile according to the design requirements, and then divide the profile acco...

Embodiment 2

[0042] like Figure 4 As shown, Embodiment 2 of the present invention provides a method for assembling a display screen, and the method for assembling includes:

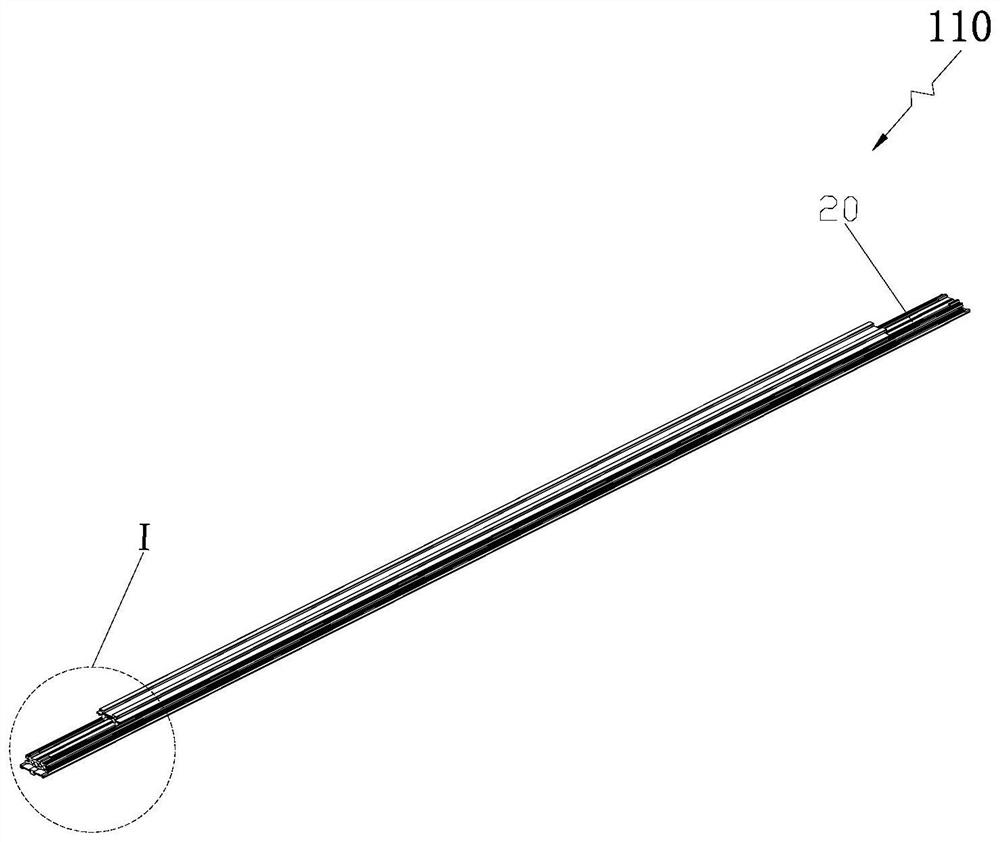

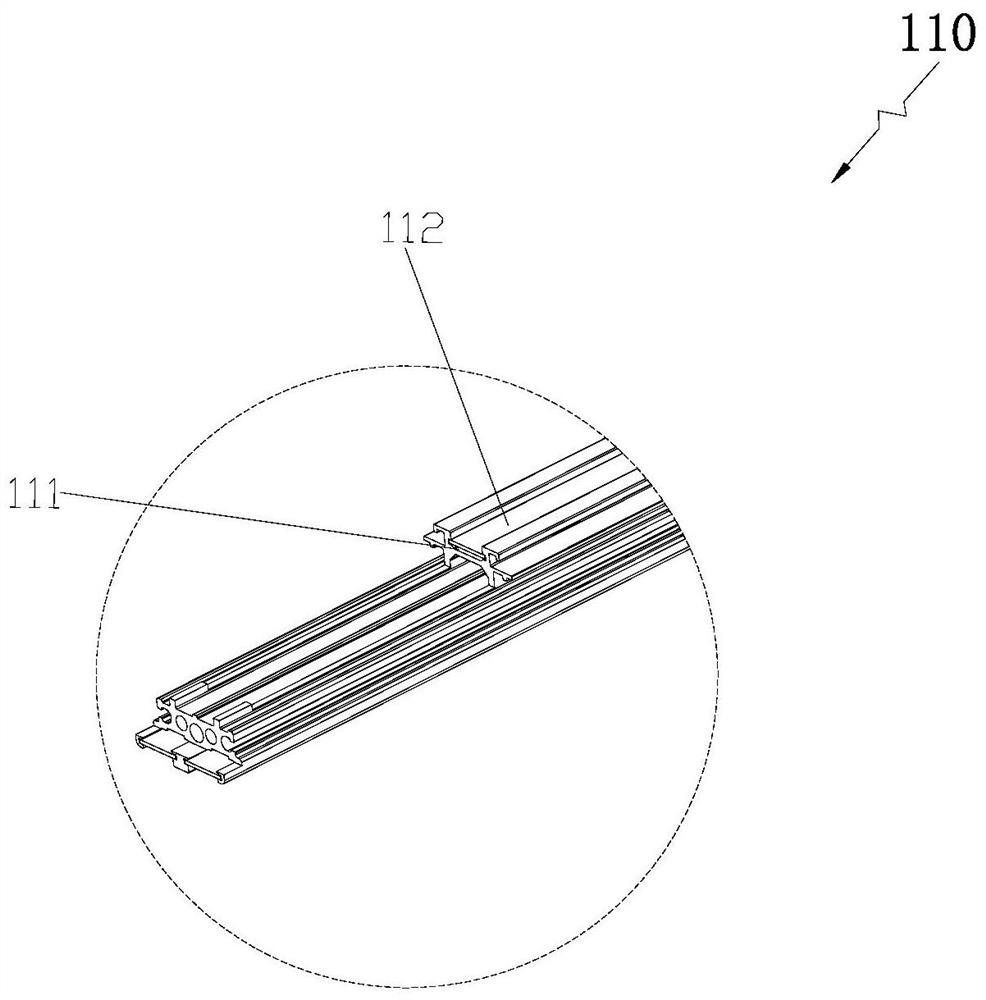

[0043] Step S210: Provide the top side beam member and the bottom side beam member, and after parallel alignment of the bottom side beam member and the top side beam member, serve as installation references for several profile members.

[0044] Specifically, as Figure 5 and Image 6 As shown, the display screen 1 assembled in this embodiment is not limited to the LED display screen, that is, the display module 100 can be an LCD display module, an OLED display module or other display modules that can be spliced in addition to the LED display module. Group. Several profile rods 110 in this embodiment need to be arranged vertically at equal intervals, therefore, it is necessary to provide a top side beam rod 120 and a bottom side beam rod 130, and the bottom side beam rod 120 and the top side beam rod 130 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com